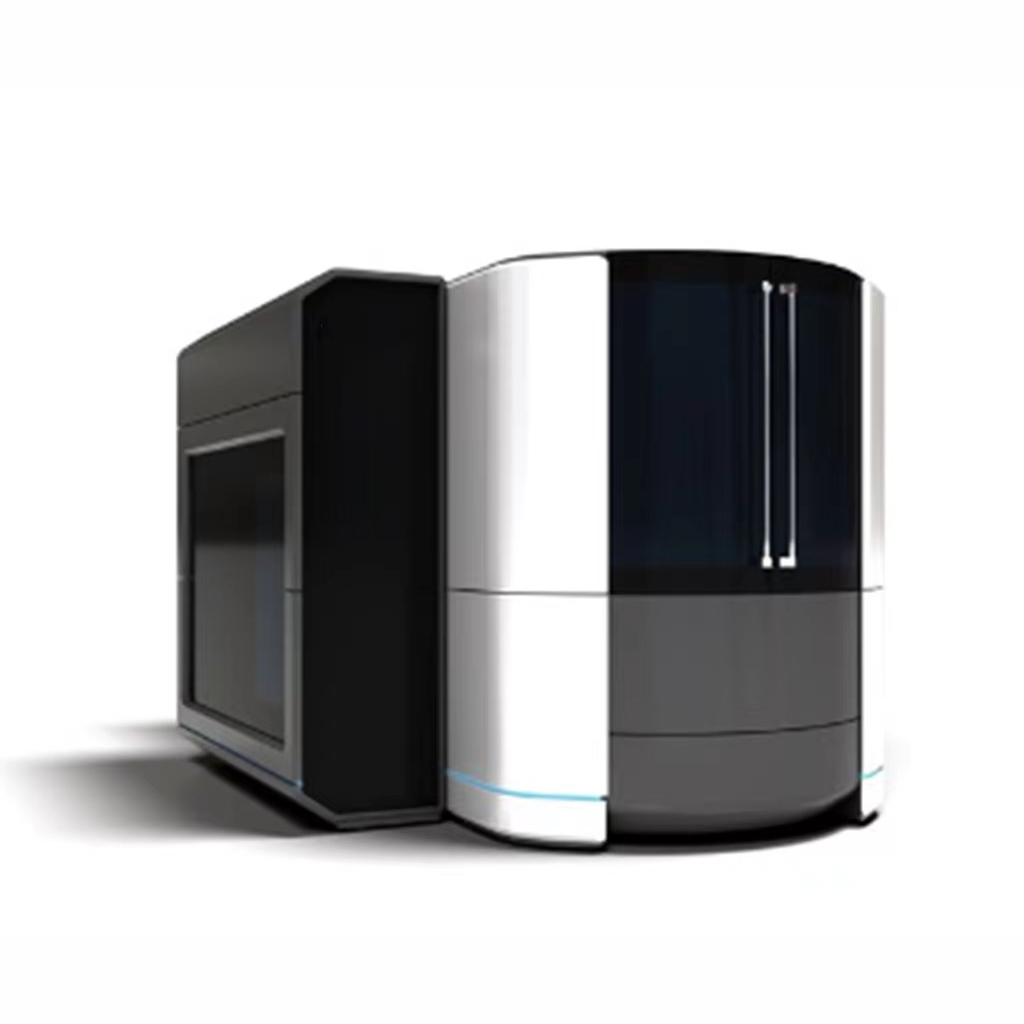

5-Axis Horizontal Machining Center

1.Product Introduction

Kaihua Mold introduces the 5-Axis Horizontal Machining Center, a revolutionary piece of machinery that aims to take your mold production to the next level. This advanced tool processing technology reduces the risks associated with tool shaking and breakage during processing, and improves the surface quality of the mold. With its high precision, efficiency, and durability, the 5-Axis Horizontal Machining Center can dramatically enhance your mold manufacturing process and help you achieve your production goals.

The 5-Axis Horizontal Machining Center offers a wide range of benefits to its users. It can easily accommodate complex parts and geometries with high accuracy and precision. Moreover, this technology allows for an increased level of flexibility in the manufacturing process as it can process multiple angles and contours at once. With its advanced features, it helps reduce processing time, increases production efficiency and reduces the incidence of errors. The result is a seamless and precise mold production process from start to finish.

At Kaihua Mold, we believe that innovation is key to staying ahead in a highly competitive market. That's why we have invested in this cutting-edge technology that outperforms the competition in several key areas. Our 5-Axis Horizontal Machining Center offers fast and smooth spindles, high rigidity, and ultra-high precision that can meet the needs of many industries. Whether you need to make complex molds for the automotive, aerospace, medical devices, or electronics industries, this technology will deliver the results you demand.

Our team of experienced and dedicated technicians are dedicated to providing you with the highest quality service and support. We offer comprehensive training, installation, maintenance, and repair services to ensure that your 5-Axis Horizontal Machining Center operates at peak performance. We also pride ourselves in our excellent customer support, so you can rest assured that you are not alone. When you choose Kaihua Mold, you choose a partner that always puts your needs first.

In short, the 5-Axis Horizontal Machining Center by Kaihua Mold is the perfect solution for your mold manufacturing needs. We guarantee that you will be satisfied with its high quality, efficiency, and performance. Contact us today to schedule a consultation and see the difference our technology can make for your business.

2.Advantages

· FANUC five axis CNC system, with support for high speed, high precision, fast and stable feed characteristics.

·Adopt imported high precision CNC dual axis indexing plate, realize five axis linkage function through NUMERICAL control system control.

·The machine adopts timing and quantitative automatic centralized oil supply lubrication system.

3.Project Cases:

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.