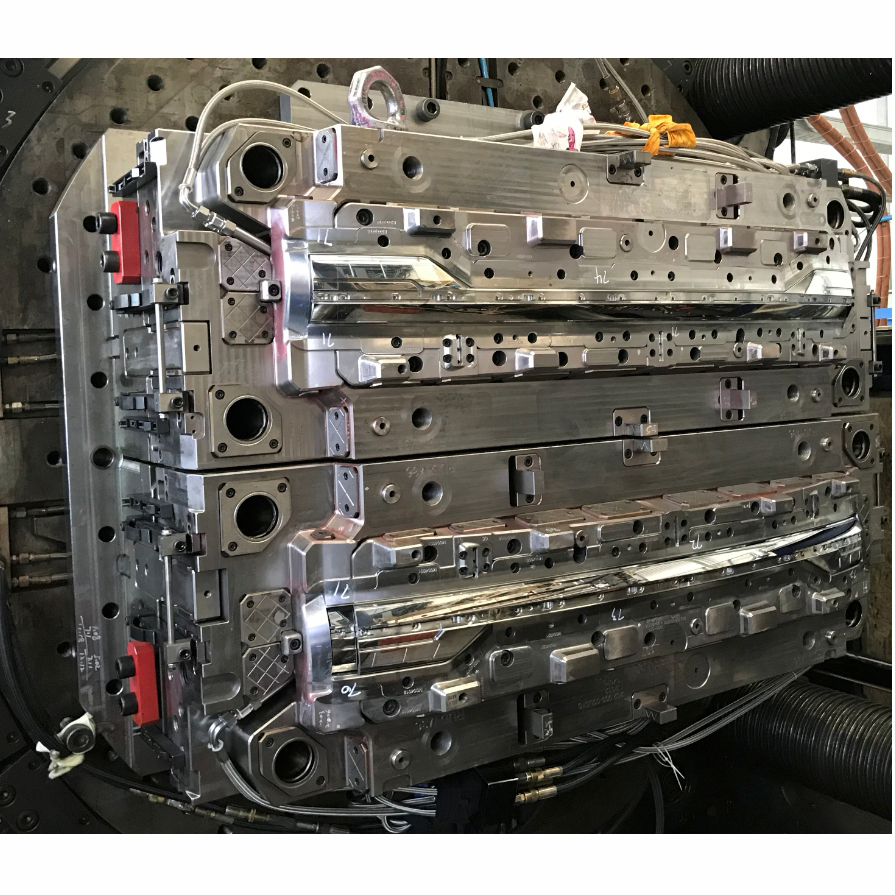

Car Bumper of Plastic Injection Mold

1.Product Introduction

At Kaihua Mold, Kaihua specialize in Car Bumper of Plastic Injection Mold that set the benchmark for precision and durability in the automotive industry. With over two decades of experience, Kaihua is dedicated to delivering unparalleled quality and innovative solutions.

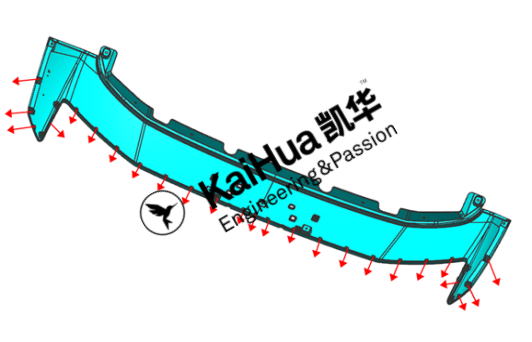

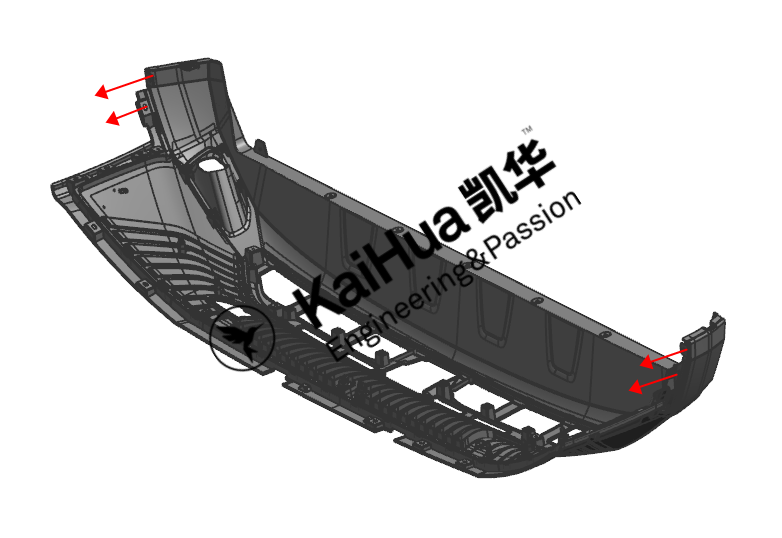

Kaihua's plastic injection mold for car bumpers offers a seamless blend of functionality and aesthetics. Crafted from high-quality materials, Car Bumper of Plastic Injection Mold ensures robust performance even under the most demanding conditions. The meticulous design process ensures that the bumper fits perfectly with various car models, providing a snug and stylish addition to your vehicle's exterior.Car Bumper of Plastic Injection Mold use of plastic injection molding technology allows for the production of bumpers with intricate details and smooth finishes. This process ensures consistency in quality and reduces production time, making it an ideal choice for both automotive manufacturers and aftermarket parts suppliers.

2.Case Product Parameters

|

Product Name |

Upper body of front bumper |

|

Plastic material |

PP+EPDM-T20 |

|

Product weight (g) |

2600 |

|

Product size |

1939X560X474 |

|

Product wall thickness(mm) |

2.8 |

|

Mold weight(t) |

29.9 |

|

Mold size |

2900*1500*1712 |

|

Injection molding machine tonnage |

2500 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

spray painting |

|

Automatic demolding requirements |

gripper |

|

Product Name |

Lower body of front bumper |

|

Plastic material |

PP+EPDM-T20 |

|

Product weight (g) |

3140 |

|

Product size |

1865X388X420 |

|

Product wall thickness(mm) |

2.8 |

|

Mold weight(t) |

22.9 |

|

Mold size |

2700*1400*1560 |

|

Injection molding machine tonnage |

2500 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

Grain |

|

Automatic demolding requirements |

gripper |

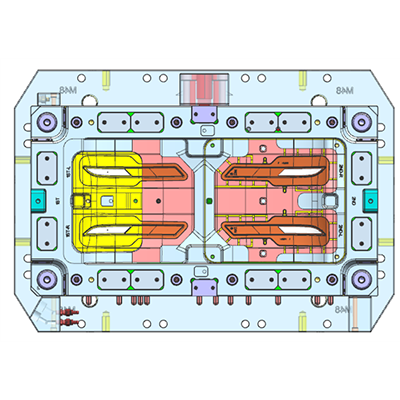

3.3.Production details

5.Product feature and application

(1)Product feature

· Durability and Strength: Fabricated using high-quality plastic materials, Kaihua car bumper mold ensures that the final product is robust and capable of withstanding minor collisions and road impacts without sustaining damage.

· Precision Engineering: With state-of-the-art injection molding technology, every car bumper is meticulously crafted to fit perfectly on various car models, ensuring a seamless installation process and a perfect aesthetic fit.

· Design Flexibility: Kaihua mold design allows for customization options, enabling you to create bumpers that cater to different stylistic preferences and aerodynamic needs.

· Cost-Effective: Injection molding is a highly efficient manufacturing process, which translates to lower production costs and more affordable pricing for end-users without compromising on quality.

(2)Product application

· Automotive Industry: Perfectly suited for OEM (Original Equipment Manufacturer) applications, Kaihua Car Bumper of Plastic Injection Mold cater to leading automakers worldwide.

· Aftermarket Parts:Car Bumper of Plastic Injection Mold ideal for producing high-quality replacement bumpers that match original specifications, ensuring vehicles maintain their safety and aesthetic standards post-collision repairs.

· Export Markets: With Kaihua robust and versatile molds, Kaihua support international markets, ensuring compliance with global standards and delivering consistent quality across borders.

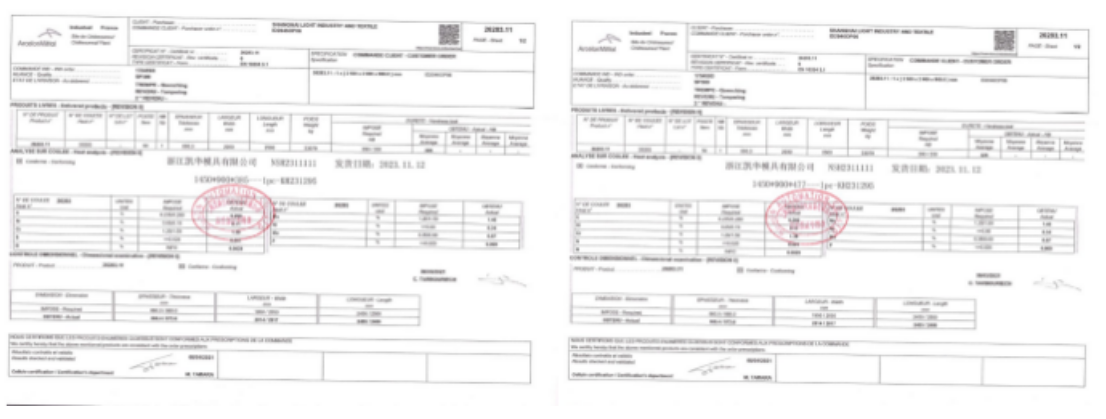

Prodect qualification

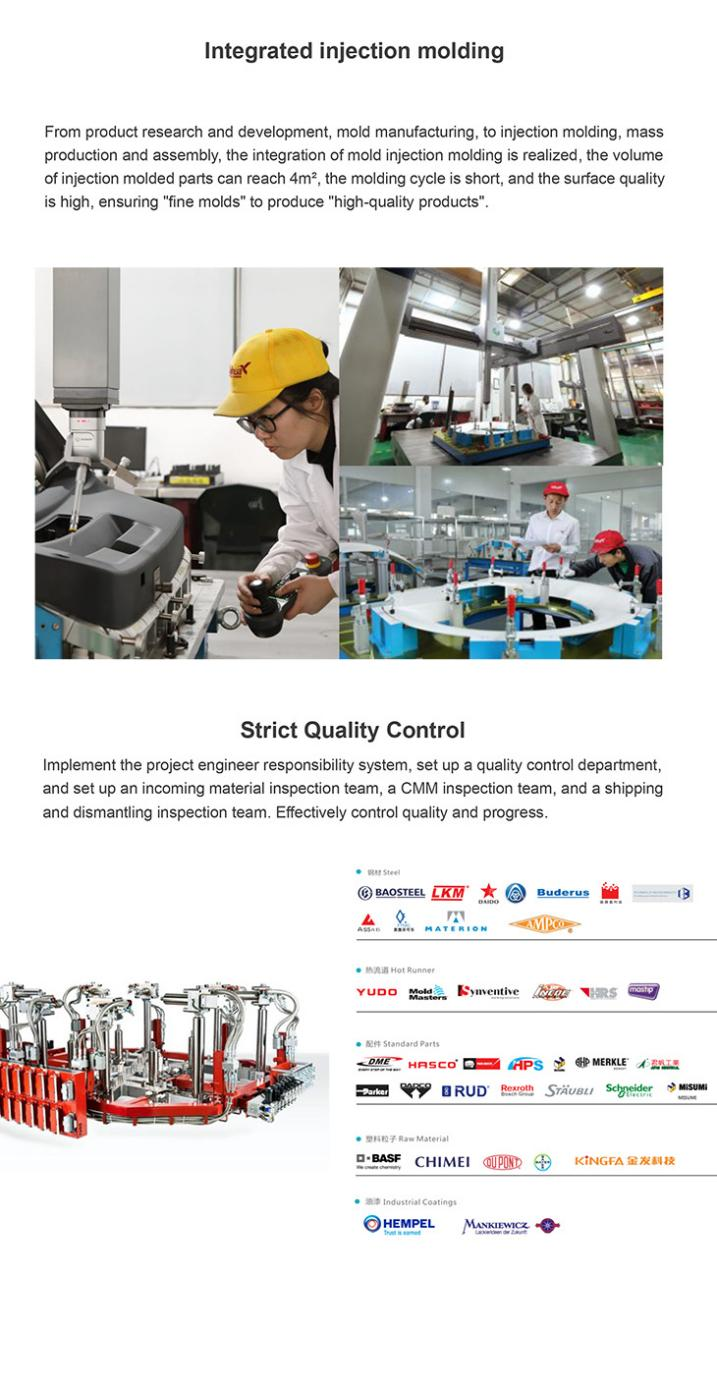

(1)Car Dashboard of Plastic Injection Mold Trial Process

· Mold Preparation: Securely close the mold to ensure it is properly aligned and ready for injection.

· Material Loading: Introduce dried plastic pellets into the hopper of the injection molding machine.

· Melting Phase: Heat the injection unit to melt the plastic pellets uniformly.

· Injection Phase: Inject the molten plastic into the mold cavity using a precision injection system.

· Pressure Maintenance: Apply consistent pressure to ensure the mold cavity is fully filled and maintains its shape during the filling process.

· Cooling Phase: Allow the injected plastic to cool and solidify within the mold, taking on the desired shape.

· Ejection: Carefully open the mold and eject the finished plastic product.

(2)Product shipment and packaging photos

(2)Design review photos

(3)Photos of the Technical Department Meeting

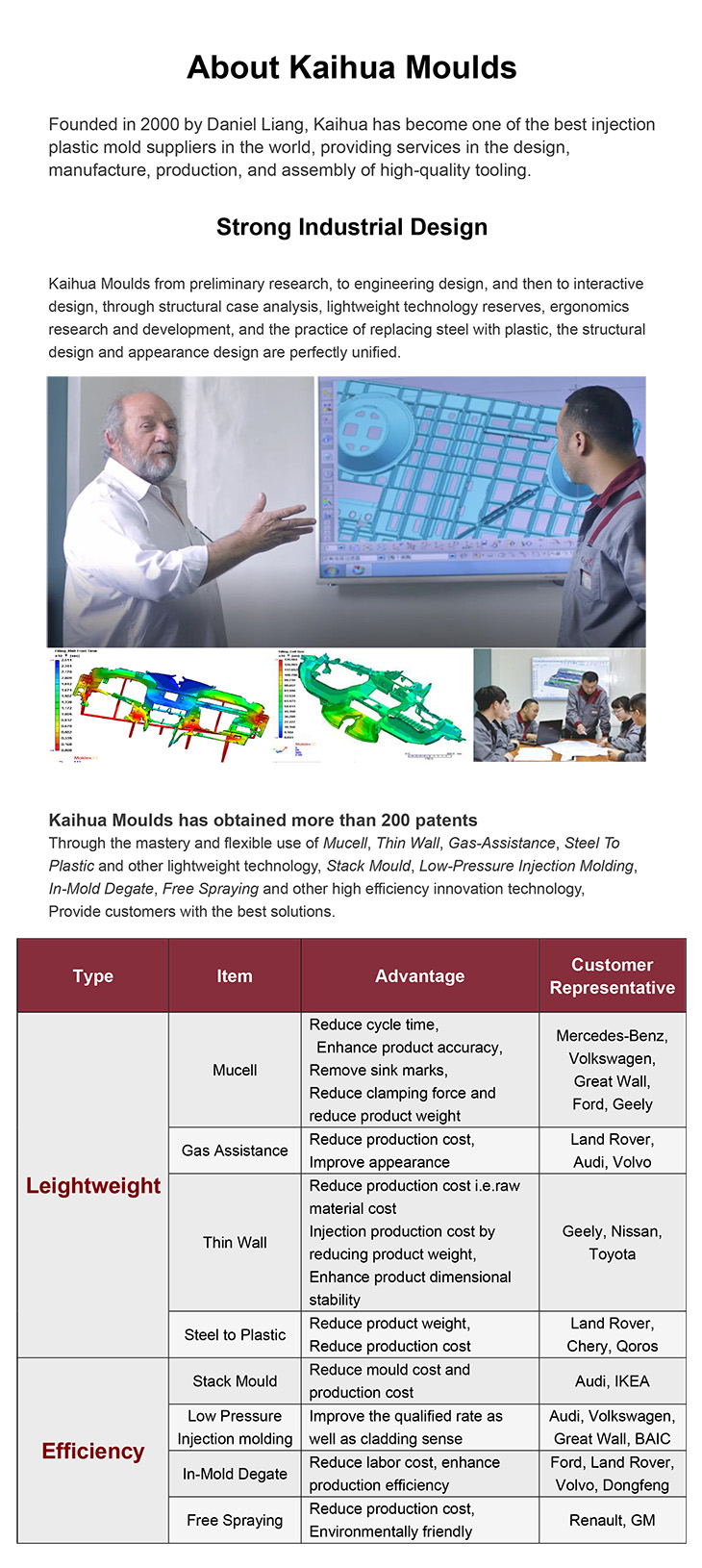

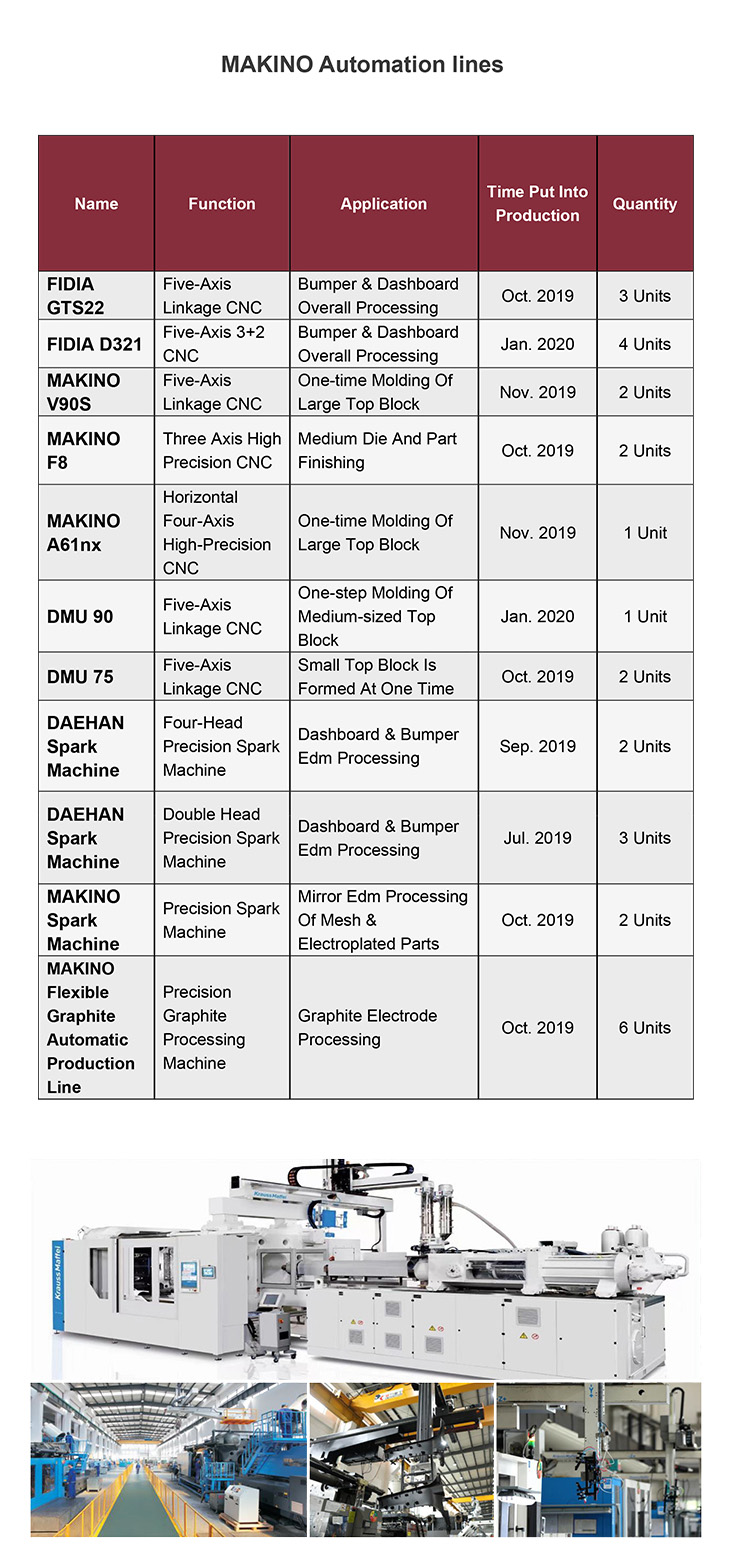

6.Kaihua Mould Advantage

8.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.