Car Dashboard of injection moulds products

1.Product Introduction

Kaihua Mold is specialize in manufacturing high-quality automotive molds, particularly for car dashboards. kaihua's car dashboards are thin-walled, large-volume components with complex shapes and numerous installation holes, designed to house various instruments and controls.

Kaihua key technology for car dashboard molds is Mucell, a revolutionary process that encapsulates tiny gas bubbles within the plastic material. This reduces the density of the material while improving its strength and stiffness, resulting in lighter weight components without compromising on durability. The Mucell process also shortens the forming cycle, improves dimensional accuracy, reduces volume shrinkage, and clamping force, making it an ideal choice for automotive applications. Kaihua's car dashboards are designed using cutting-edge software such as DFM, CAE, and 3D design, ensuring precision and functionality. Kaihua offer custom Mockup Sample services, enabling customers to test new products and identify any defects before full-scale production. This reduces the risk of product R&D and overall costs, while increasing efficiency in the production process.

2.Case Product Parameters

| Product Name | U718 Lincoln Navigator SUV |

| Mat'l grade | 30%LGPP |

| Mold size | 2710x1890x1700mm |

| Mold weight | 34.5T |

| Molding cycle | 58s |

| Hot runner | 17-point valve gate |

| Demolding requirement | Gripper |

| Mold shrinkage | 0.42% |

| Physical weight | 3571g |

| Product size | 1585 x 700 x 475mm |

| Mat'l Spec | WSS M99D514-A1 |

| Mold material | DIN 1.2738HH |

| Ejection | hydraulic ejection |

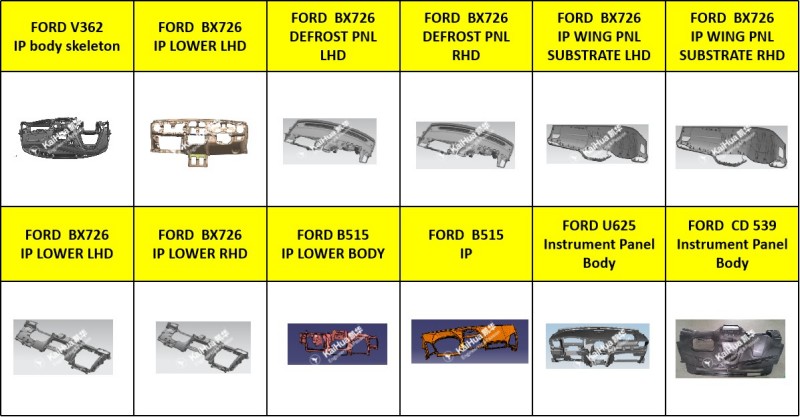

3.Product Display

• FORD V362 IP body skeleton

• FORD BX726 DEFROST PNL LHD

• FORD BX726 IP WING PNL SUBSTRATE LHD

• FORD BX726 IP WING PNL SUBSTRATE RHD

• FORD BX726 IP LOWER RHD

• FORD B515 Instrument Panel Body

• FORD BX726 IP LOWER LHD

• FORD B515IP LOWER BODY

• FORD BX726 IP LOWER LHD

• FORD BX726 IP LOWER LHD

• FORD U625 Instrument Panel Body

• FORD CD 539 Instrument Panel Body

4.Production details

(1)Water Interface

(2)Hot runner socket

(3)Front View and Rear View

5.Product feature and application

(1)Features:

●Precision Craftsmanship: Kaihua car dashboards are precision crafted using Mucell technology, ensuring the highest levels of accuracy and quality.

●Lightweight and Durable: Mucell technology reduces the weight of the car dashboards while maintaining their durability and strength, making them ideal for modern vehicles.

●Cost-Effective: The Mucell process reduces material usage and manufacturing costs, allowing Kaihua to offer competitive pricing without compromising on quality.

●Enhanced Dimensional Accuracy: Mucell technology greatly improves the dimensional accuracy of the dashboards, ensuring a perfect fit for various automotive models.

●Environmentally Friendly: The reduction in material usage and lighter weight components have a lower environmental impact, making Kaihua car dashboards ideal for electric and hybrid vehicles.

(2)Applications:

Kaihua Car Dashboard Injection Mold with Mucell technology is widely used in the automotive industry, particularly for modern car models that require lightweight, durable, and aesthetically pleasing dashboards. Kaihua car dashboards are designed to meet the specific needs of automotive manufacturers, ensuring a perfect fit for various models and a competitive edge in the market. Whether you're looking to reduce costs, improve production efficiency, or enhance the overall quality of your automotive components, Kaihua Mould is your trusted partner.

6.Prodect qualification

(1)Production process

●Mold Preparation: Secure and position the mold correctly to prepare for the production cycle.

●Material Input: Place the pre-dried polymer granules into the feeding chamber of the injection molding equipment.

●Thermal Processing: Activate the heating system within the machine to transform the solid plastic granules into a molten state.

●Material Injection: Transfer the liquefied plastic material into the prepared mold cavity via an injection mechanism.

●Pressure Application: Apply consistent pressure within the mold to ensure the plastic fills all details of the mold design.

●Setting Phase: Allow the injected material to cool inside the mold, thereby stabilizing its form according to the mold's specifications.

●Product Ejection: Once cooled, separate the mold components and extract the finished plastic item.

(2)Car Dashboard Mould Video

(3)Product shipment and packaging photos

(4)Technical team

| Responsibilities of project members | Main responsibilities |

| project manager

|

Supervise the entire project planning and control the quality, time, and cost of the project |

| Quality Manager

|

Responsible for project quality matters |

| salesman | Responsible for project business and logistics work |

| Design team leader | Responsible for reviewing and guiding product analysis and design, as well as mold structure design |

| Process Supervisor

|

Responsible for the development of mold production processes and production management |

| Mold Supervisor | Responsible for the research and assembly of molds, as well as guidance on mold technology |

(5)Design review photos

(6)Photos of the Technical Department Meeting

(7)Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

Click here,gain a deeper understanding of Kaihua's advantages,experience our professional strength and quality assurance!

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.

Car Dashboard Mould Video

Kaihua Mold is a professional automobile dashboard mould manufacturers and all-round solution provider. Our automobile Instrument Panel Injection Molds ( IP Mold ) are of the highest quality and are designed to meet the specific needs of automotive manufacturers. Our team of experts works closely with clients to ensure that their needs are fully met, and we are committed to providing the best possible service to our customers. We specialize in injection moulding automotive mold and are one of the leading providers in China. Trust Kaihua Mold to provide you with the best quality products and services for all your automobile instrument panel injection molds ( IP Mold ) needs.

At Kaihua Mold, we specialize in automobile Instrument Panel Injection Molds (IP Molds) that set the benchmark for precision and durability in the automotive industry. With over two decades of experience, Kaihua is dedicated to delivering unparalleled quality and innovative solutions.

Key Features & Benefits:

●Precision Engineering: Leveraging advanced CAD/CAM technology, Kaihua Automobile Dashboard Mould are meticulously engineered to meet the stringent standards of modern automotive manufacturers, ensuring a perfect fit every time.

●Superior Durability: Constructed from high-grade steel, Kaihua Automobile Dashboard Mould are built to endure harsh environments and maintain their integrity over extended periods, providing long-term reliability and reduced maintenance costs.

●Customization Flexibility: Tailored to your specific needs, Kaihua china offer both OEM and ODM services, enabling you to bring your unique designs to life while benefiting from Kaihua extensive expertise.

●Innovative Technology: Equipped with state-of-the-art machinery, Kaihua china production process integrates the latest advancements in mold-making technology, allowing Kaihua to deliver superior results efficiently.

●Expert Team: Kaihua team of seasoned designers and engineers brings years of knowledge and skill to each project, ensuring that every Automobile Dashboard Mould not only meets but exceeds expectations.

●Comprehensive Support: From initial consultation through to post-delivery support, Kaihua china provide comprehensive services that ensure a seamless experience and lasting satisfaction.