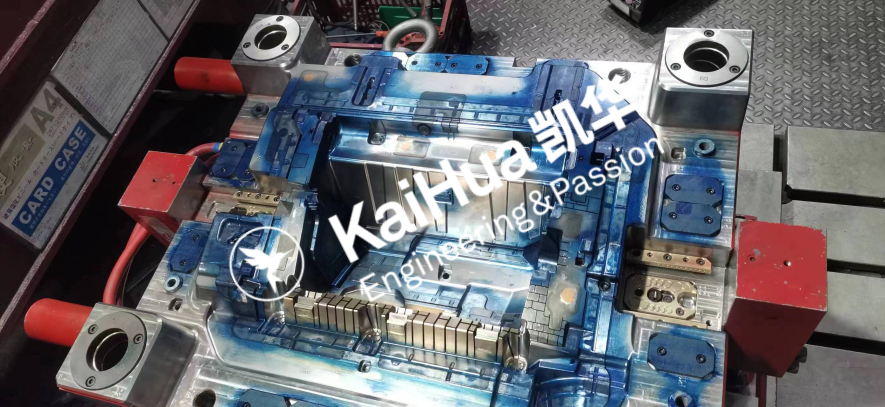

Car Glove Box Plastic Injection Mold

1.Product Introduction

Welcome to KaiHua, where innovation meets excellence in plastic injection molding. Kaihua Car Glove Box Plastic Injection Mold is a testament to our commitment to delivering top-notch automotive parts. Crafted with cutting-edge technology and stringent quality control, this mold ensures precise replication of Car Glove Box components, meeting the industry's highest standards. KaiHua mould excels in providing customized solutions, ensuring that each mold aligns perfectly with your design specifications and production requirements. Partner with KaiHua company for reliable, efficient, and cost-effective molding solutions.

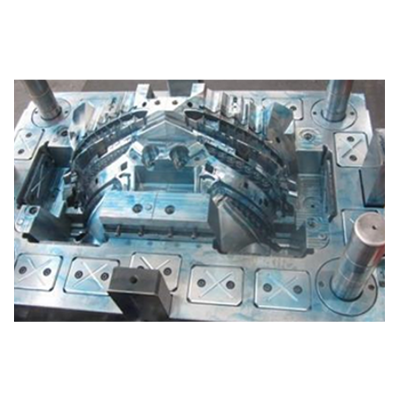

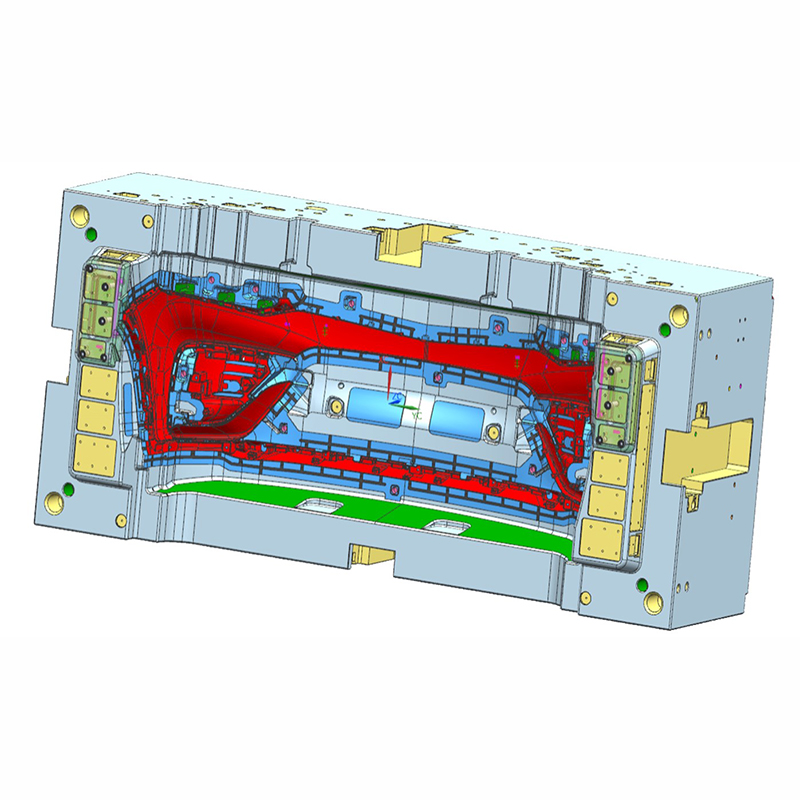

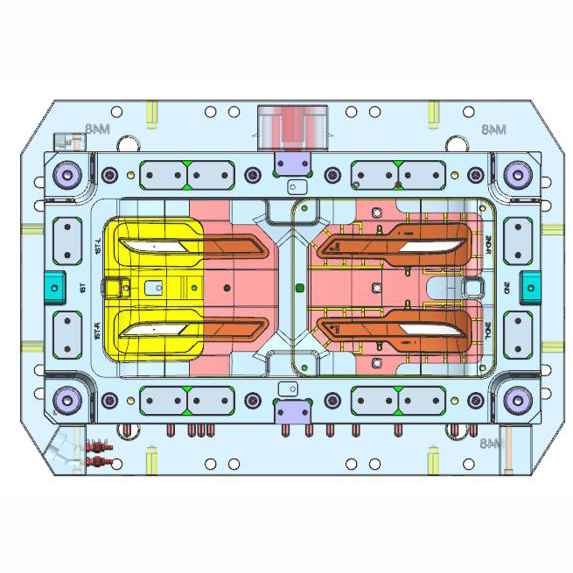

2.Case Product Parameters

|

Part Name |

Glove box surround |

|

Product Images |

|

|

Number of Mold Cavities |

1 |

|

Mat'l Grade |

P/E-MD20 Impact Mod |

|

Part Weight(g) |

820g |

|

Wall Stock(mm) |

3 |

|

Mold Weight(kg) |

11065 |

|

Product Size |

536X377X210 |

|

Mold Size |

2900X1500X1712 |

|

Grain or Electroplate |

fine grain in appearance surface,polish in non-apperance surface |

|

Demolding Requirement |

gripper |

|

Injection molding machine(t) |

650 |

3.3.Production details

4.Product feature and application

(1)Product Feature

Precision Craftsmanship: Leveraging advanced plastic injection molding techniques, KaiHua mold guarantees impeccable detail and accuracy in every Car Glove Box produced.

Durability & Strength: Engineered using high-grade materials, Kaihua Car Glove Box Plastic Injection Mold ensures parts that withstand the test of time, maintaining their structural integrity even under heavy use.

Design Flexibility: KaiHua offers extensive customization options, allowing you to tailor the mold to your exact design specifications, ensuring a perfect fit for your automotive interiors.

Efficient Production: Kaihua state-of-the-art machinery and processes enhance production efficiency, reducing lead times and boosting your manufacturing capacity.

Cost-Effective Solutions: With KaiHua, you benefit from competitive pricing without compromising on quality, making KaiHua Car Glove Box Plastic Injection Mold an excellent value proposition.

(2)Application

The Car Glove Box Plastic Injection Mold from KaiHua is ideal for automotive manufacturers and suppliers seeking to enhance their interior components. Suitable for a wide range of vehicle models, KaiHua mold produces glove boxes that are not only functional but also add a touch of elegance to the cabin. Whether you're looking to upgrade existing designs or develop new prototypes, KaiHua's expertise in plastic injection molding ensures that your Car Glove Box meets all functional, aesthetic, and safety requirements. Trust Kaihua commitment to excellence and join the ranks of satisfied clients who have benefited from KaiHua's innovative and reliable molding solutions.

5.Product qualification

(1)Product shipment and packaging photos

(2)Design review photos

(3)Photos of the Technical Department Meeting

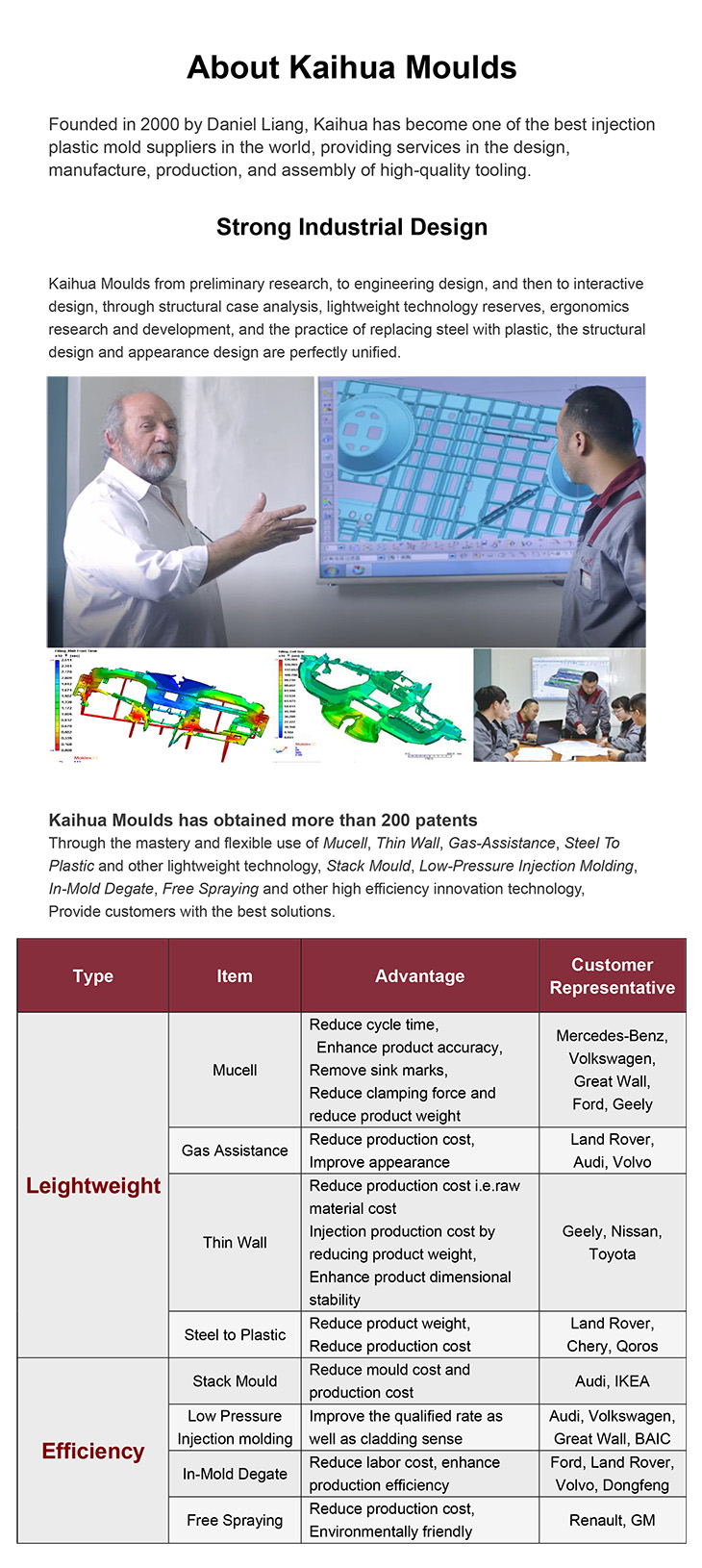

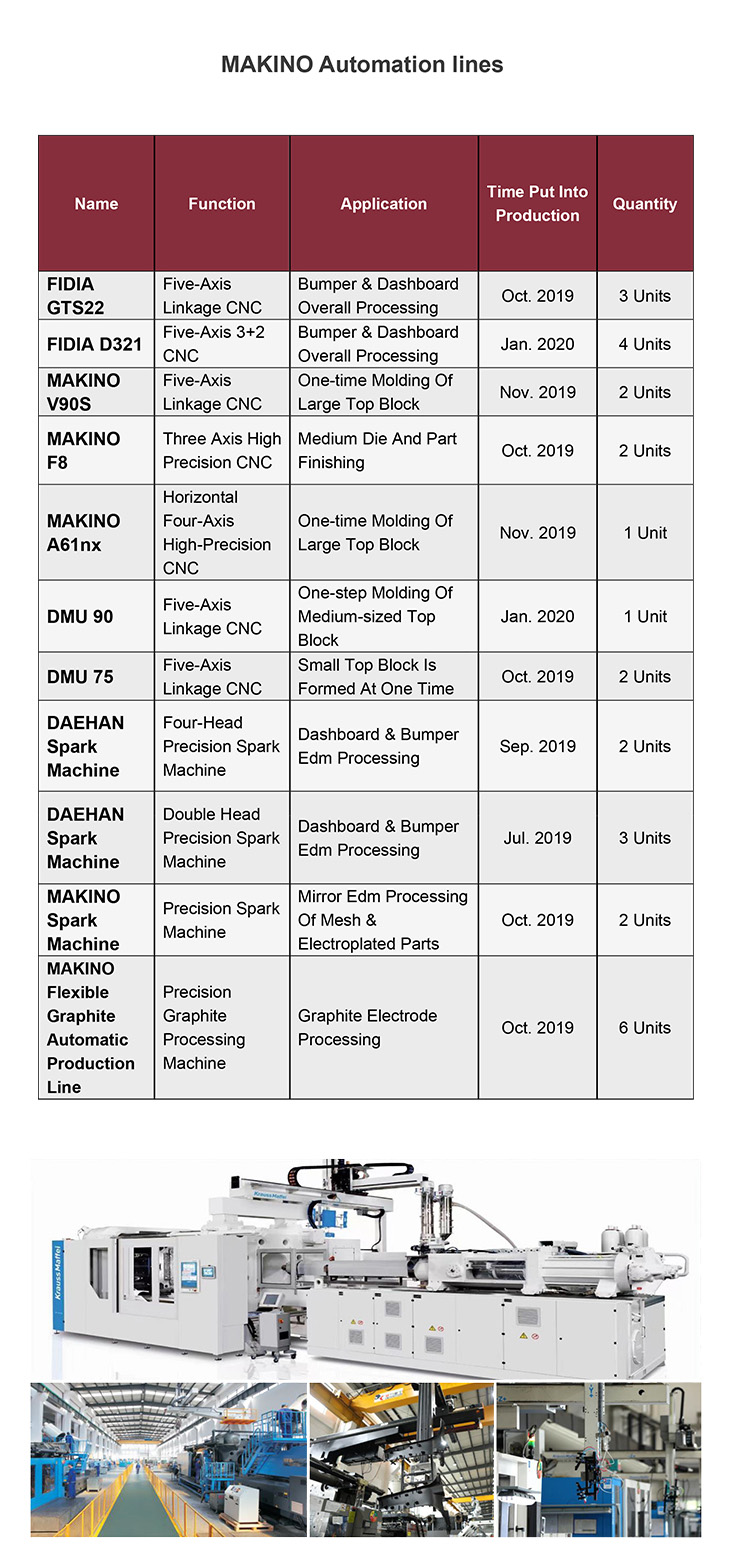

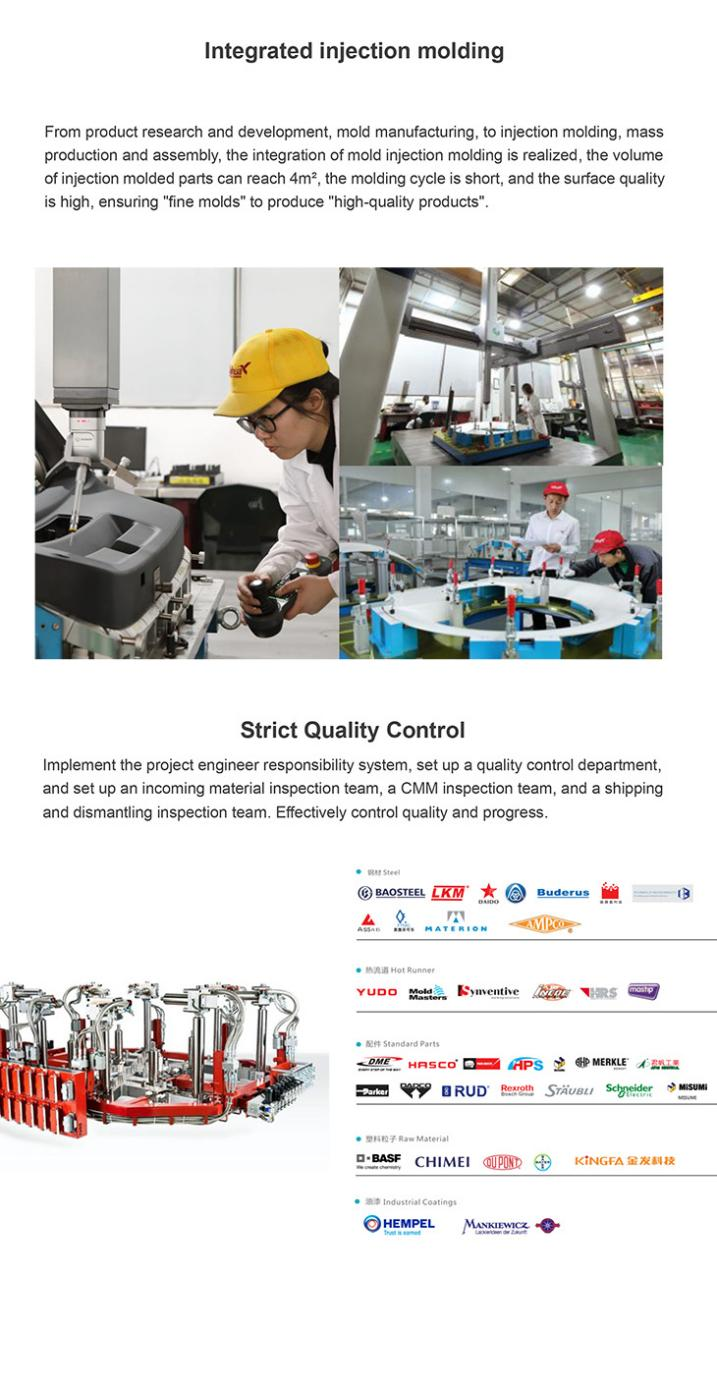

6.Kaihua Mould Advantage

8.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.