China wholesale China Sheet Metal Plate Stamping Moulds Factory – Internal Parting Car Bumper Mould with Thin wall Design – KAIHUA

China wholesale China Sheet Metal Plate Stamping Moulds Factory – Internal Parting Car Bumper Mould with Thin wall Design – KAIHUA Detail:

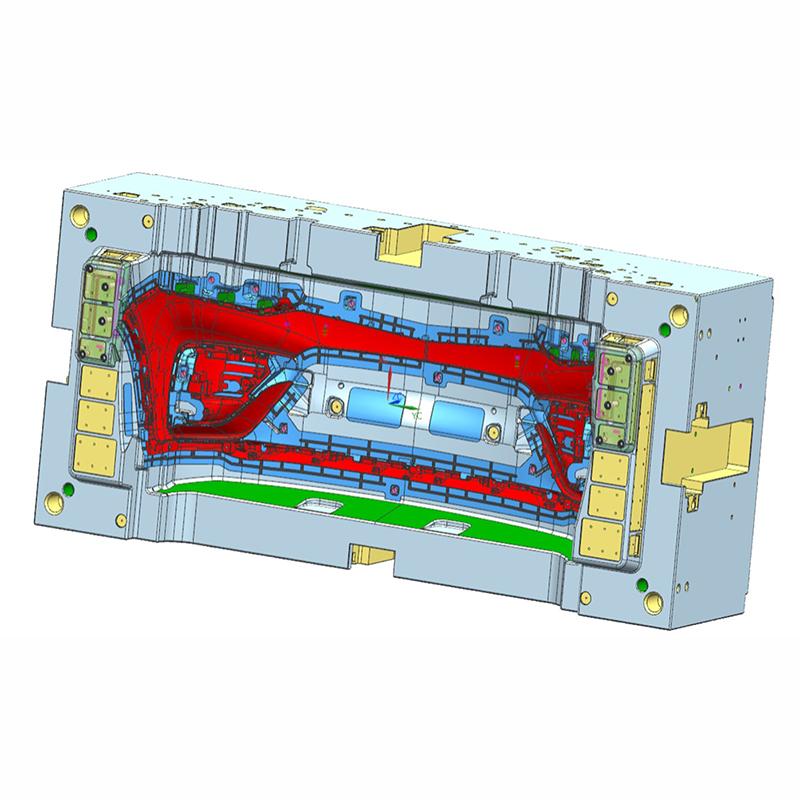

1.Product Introduction

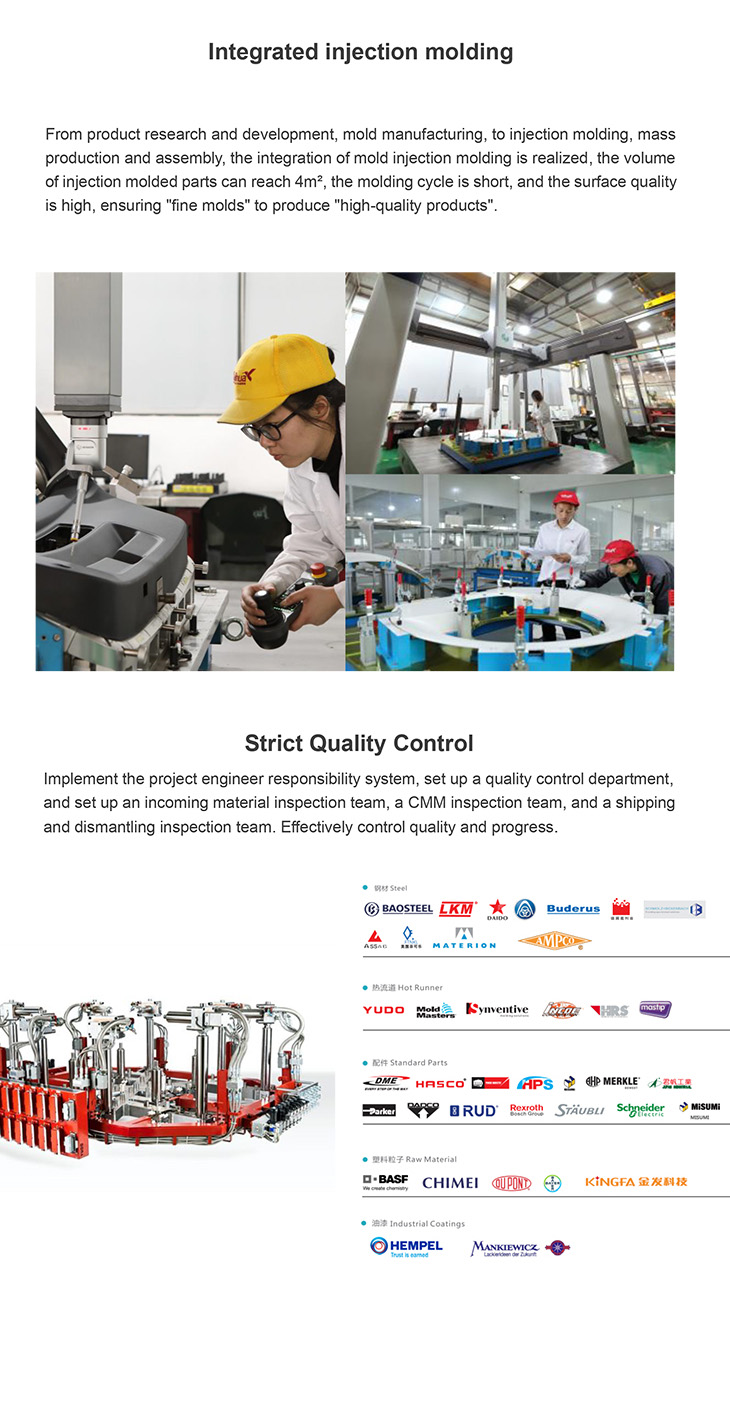

We can provide customers with the best solutions for Automotive Plastic Injection Molding for Internal Parting Car Bumper.

Kaihua Service include: Product Design, Mold Design, Mold Making, Products Research & Development & Produce, Provide Processing Injection Molding For Tier 1.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | P20, 718, 8407, Nak80, H13, S136, DIN 1.2738, DINt |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc, or your requirement |

| Shaping Mode: | Plastic Injection Mould |

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Quote | According to Samples, Drawing and Specific Require |

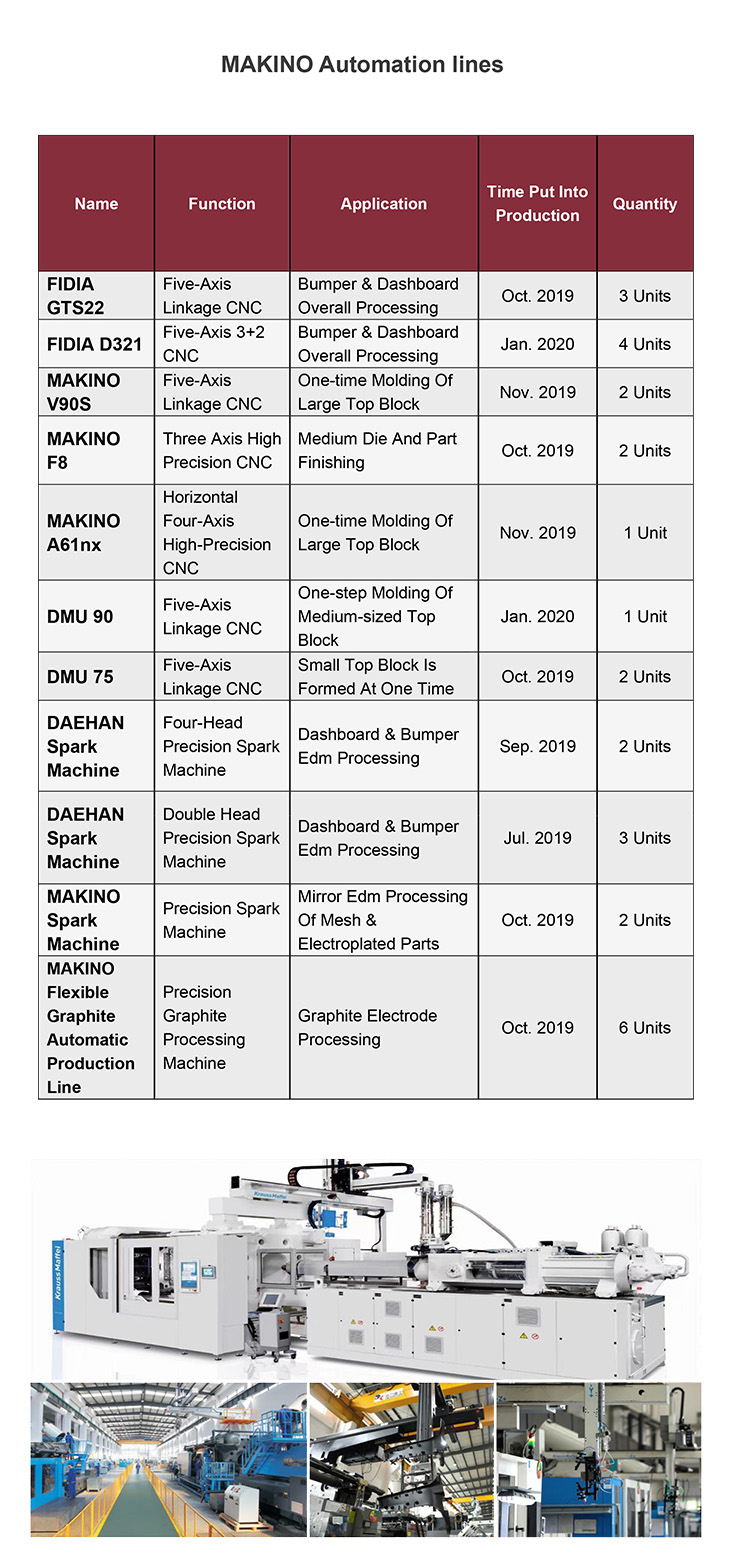

| Production Capacity | 2400 Sets/Year |

| Design Software | CATIA, UG |

3.Product Feature and Application

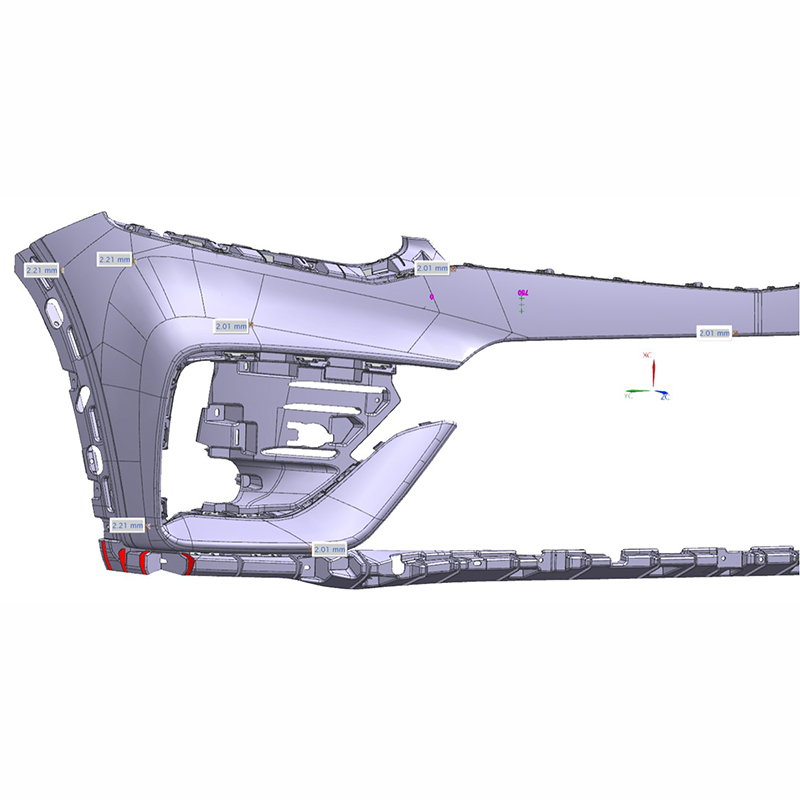

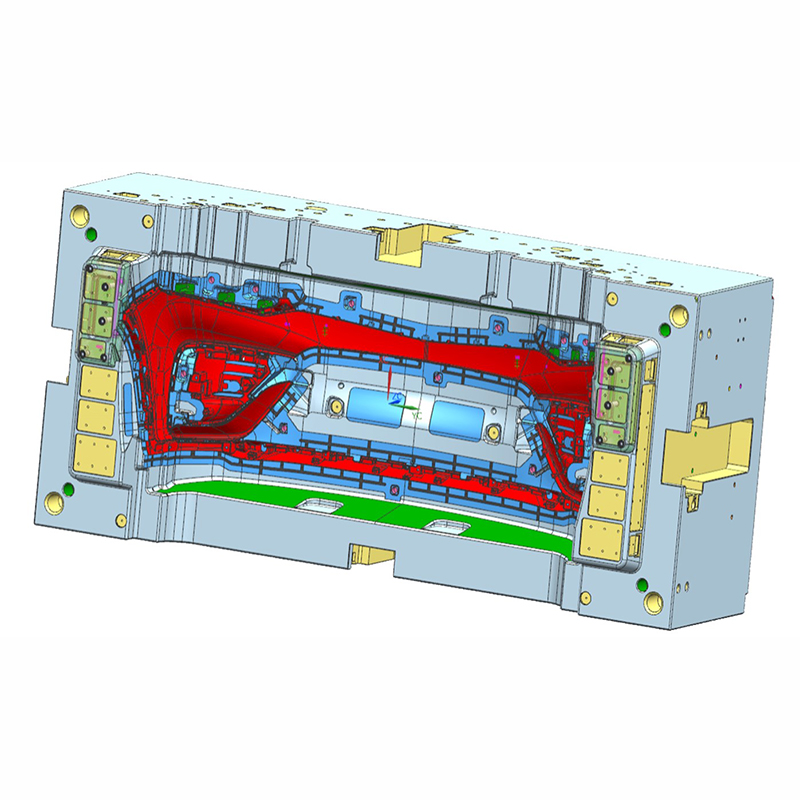

Technical Features : Internal Parting Car Bumper

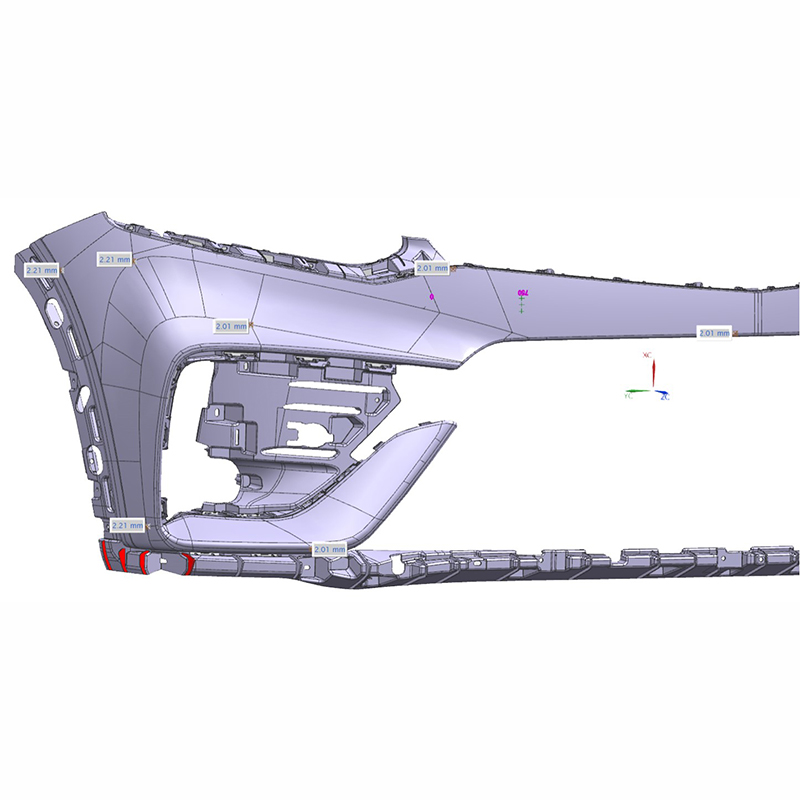

2.Unequal thin-wall design

The middle area is 2.0mm, and the ends on both sides are thickened gradually to 2.2mm.

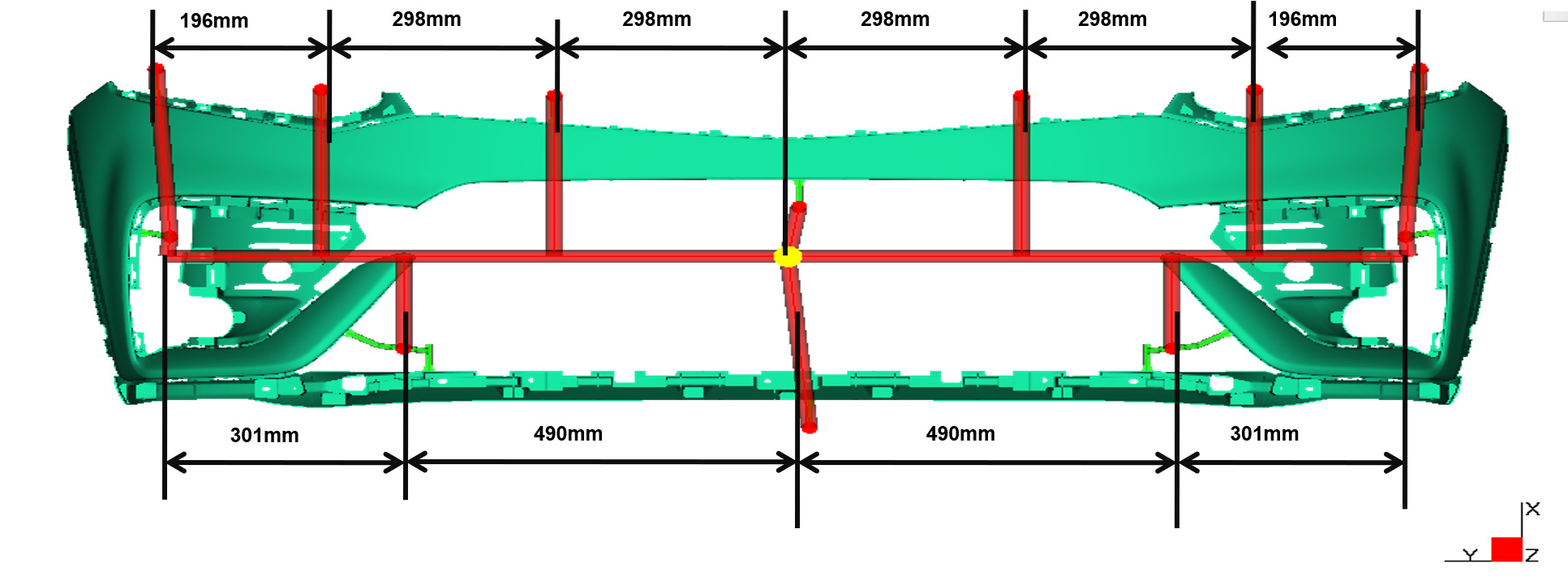

2.Hot runner scheme

2.Hot runner scheme

The hot runner scheme using Synventive Sequence valve gate 12 drops.

3.Simulated fill time (About 7.1s)

3.Simulated fill time (About 7.1s)

4.Cavity parting technology

4.Cavity parting technology

The internal parting bumper is perfectly injection-molded at one time through the secondary track change track control technology, therefor ensuring the appearance quality of the bumper and saving the processing procedures and processing costs of plastic parts.

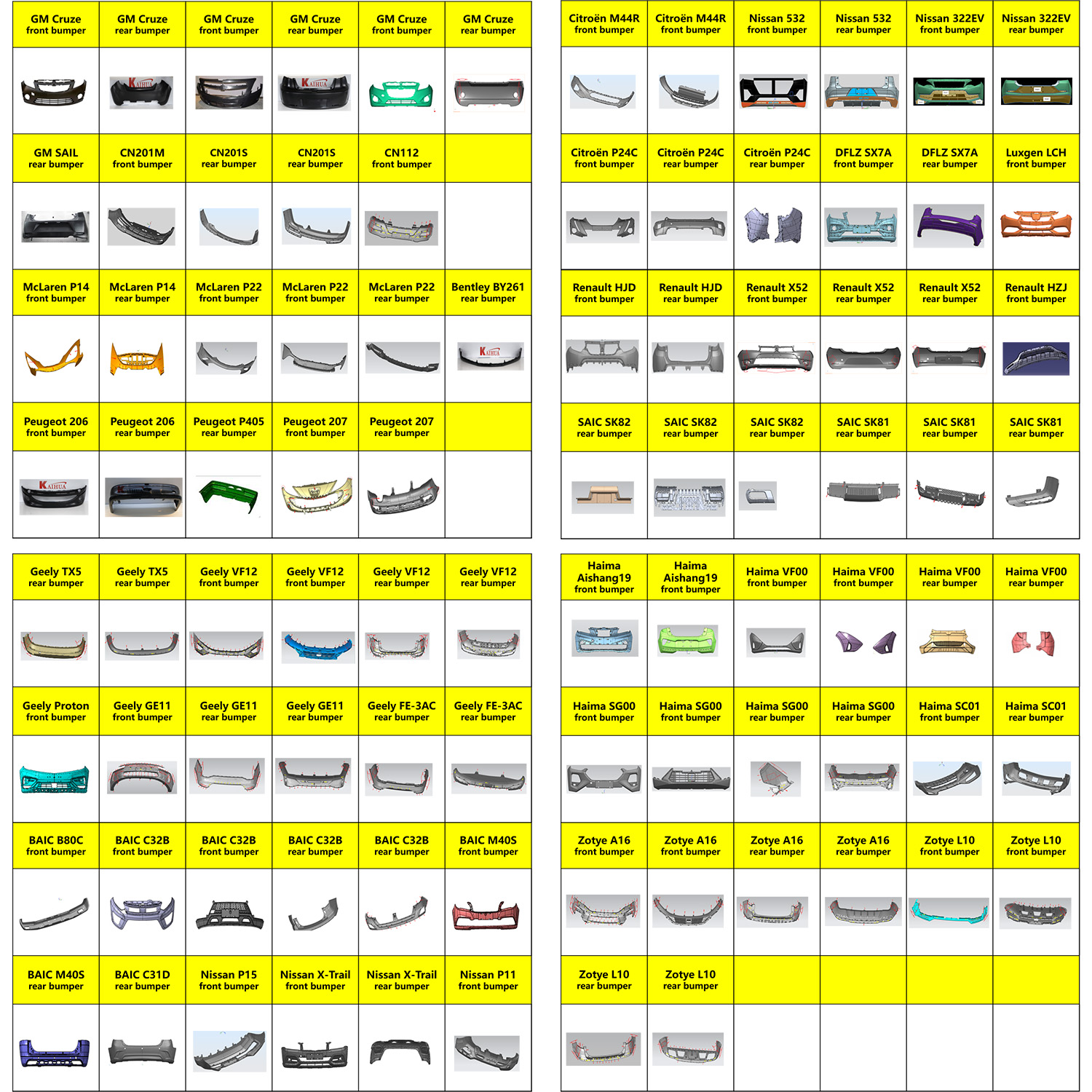

4. Cooperation Cases

Product detail pictures:

Related Product Guide:

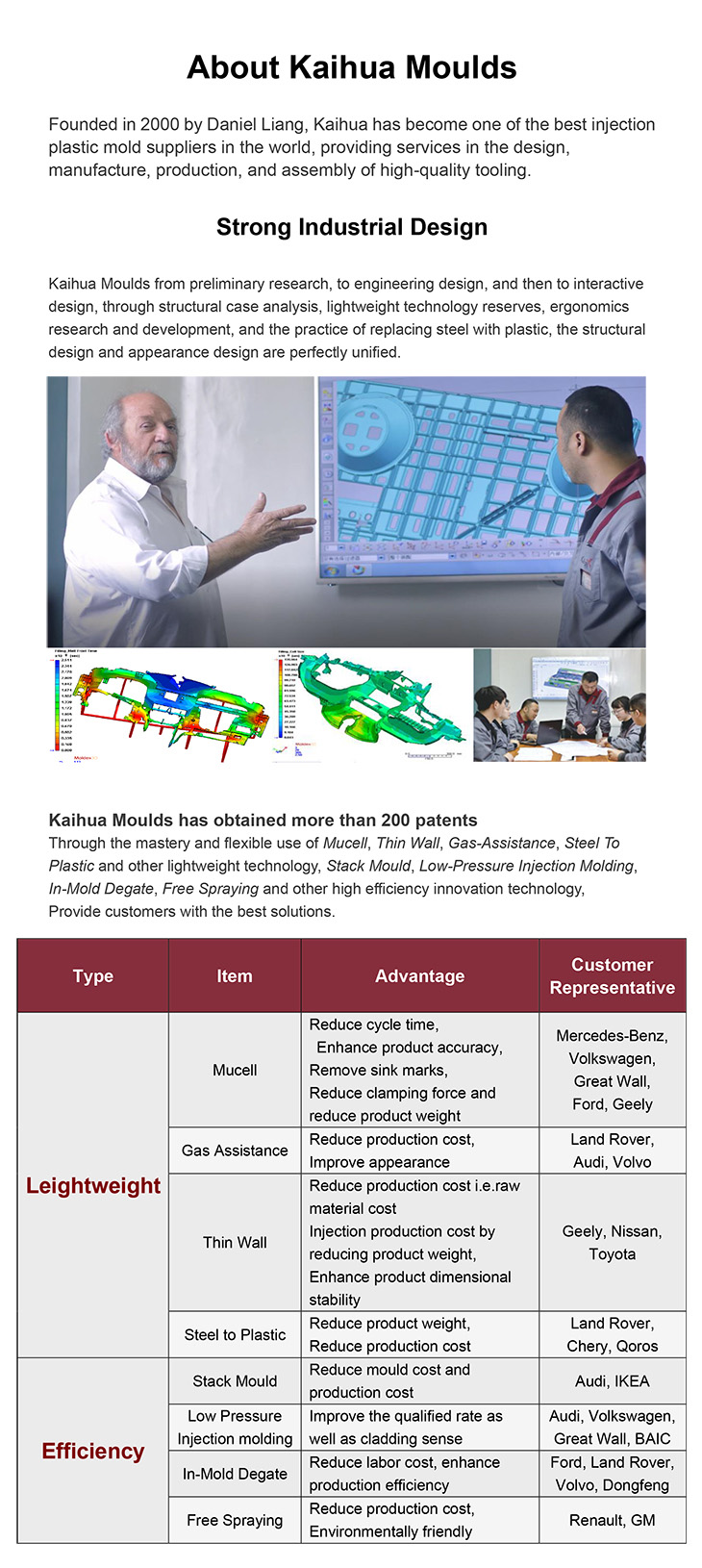

Our goal is to satisfy our customers by offering golden service, good price and high quality for China wholesale China Sheet Metal Plate Stamping Moulds Factory – Internal Parting Car Bumper Mould with Thin wall Design – KAIHUA , The product will supply to all over the world, such as: Bangalore, Auckland, Turkmenistan, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products and solutions have been exported to more than 15 countries in the world and have been widely used by customers.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.