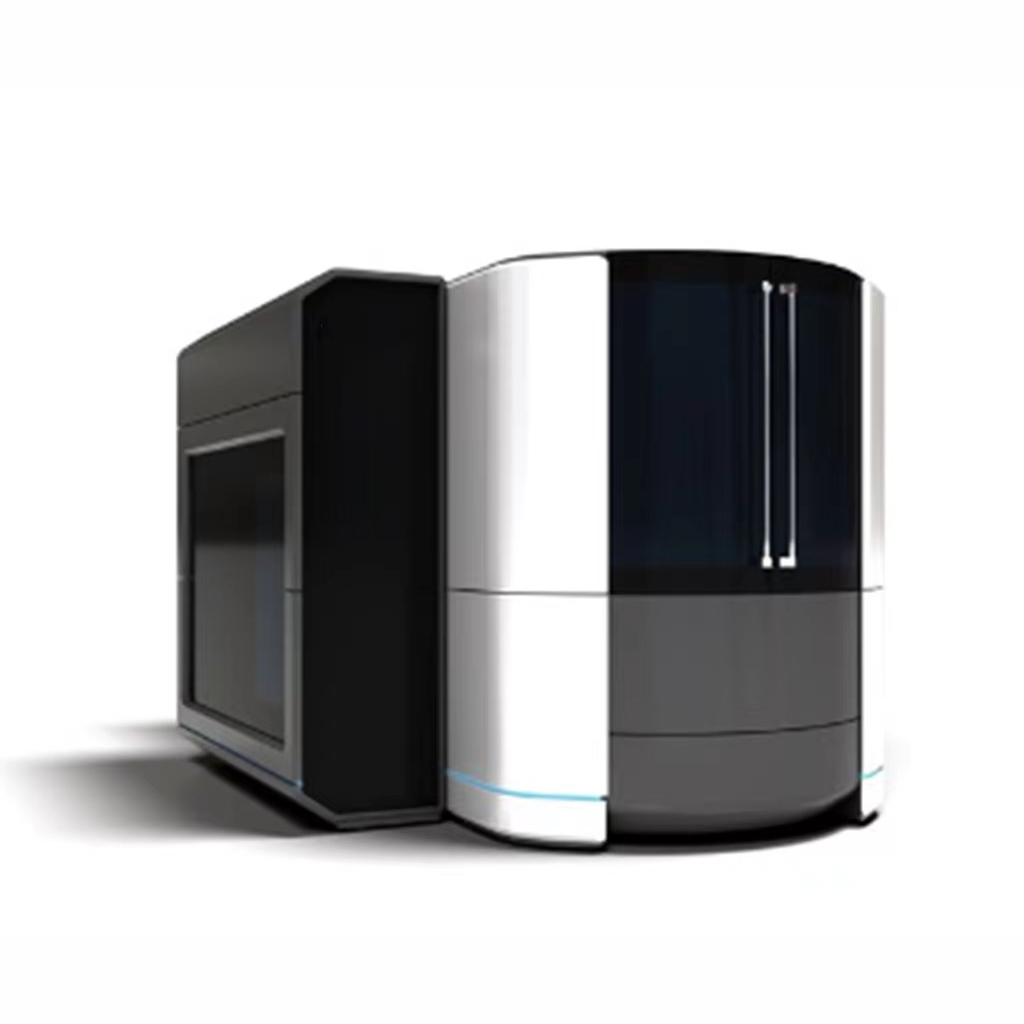

Double Color Injection Machine

1.Product Introduction

Double Color Injection Machine for Improved Product Aesthetics and Efficiency

Double color injection is a popular molding technique that involves the injection of two different materials into the same mold to produce parts with two different colors and/or materials. This process is highly efficient and can result in improved product aesthetics, functionality, and durability.

At our company, we offer a range of high-quality double color injection machines that are designed to ensure precise and efficient production of double color parts. Our machines are equipped with advanced technologies and features that enable fast and accurate injection of two different materials with minimal waste and maximum precision.

One of our key strengths is our partnership with Kaihua Mold, a leading mold manufacturer that specializes in the production of high-quality double color molds. With their expertise and our advanced double color injection machines, we can provide our customers with a comprehensive solution for their double color molding needs.

Our double color injection machines are ideal for a wide range of applications, including automotive parts, electronic components, household appliances, and more. They are highly customizable and can be tailored to meet your specific requirements, including the type of materials to be used, the shape and size of the parts, and the desired level of precision and efficiency.

In addition to our high-quality double color injection machines, we also provide comprehensive technical support and after-sales service to ensure that your production process runs smoothly and efficiently. We are committed to delivering the highest quality products and services to our customers and strive to exceed their expectations every time.

If you are looking for a reliable partner for your double color injection needs, contact us today to learn more about our products and services. We are here to help you achieve your production goals and take your business to the next level.

2.Advantages

· Reliable and durable

The high wear-resistant surface of the turntable doesn’t contact with the die wall when rotating, and the friction force is minimal, which can reduce the fault caused by abrasion.

·Diversity selection

The turntable is equipped with two sets of neutron and mold water transport devices to choose from oil, water, gas, electricity, and circuit.

·Humanized design

The turntable support structure is specially designed to effectively prevent the turntable from tilting forward and sagging after the mold is installed.

·Safe and secure

When the turntable completes the stop position, the mold positioning hole on the disk surface is reconfirmed before closing the mold to protect the safety of the mold from damage.

·Wide range of applications

This machine is equipped with a reciprocating 180-degree turntable on the movable template, which can place two pairs of two-color molds to produce products of two different materials.

·Precise and stable

High-efficiency servo drive gear transmission structure, fast and stable rotation, accurate stop position.

3.Detail

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.