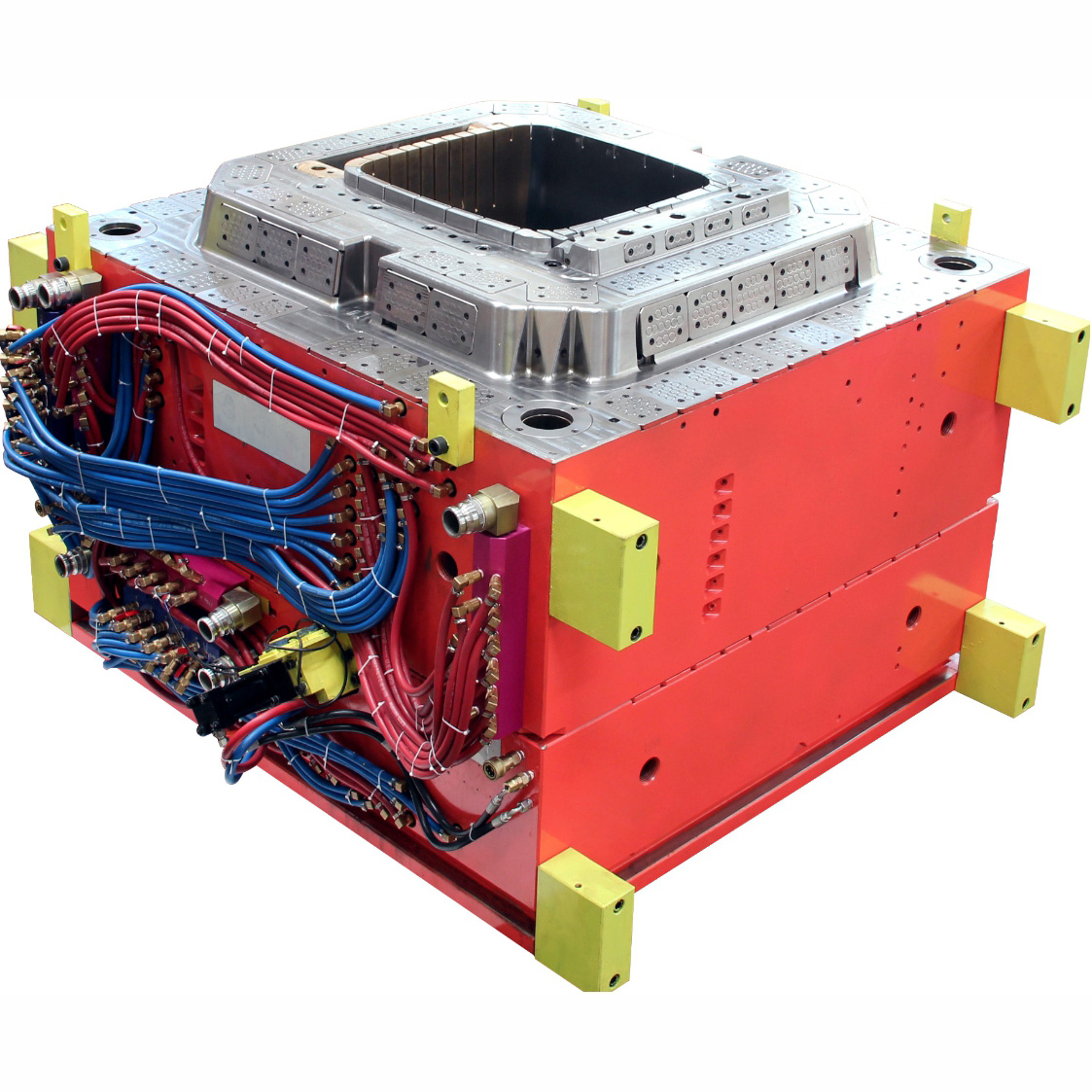

Double-deck Plastic Pallet Mould of Injection Mold

1.Product Introduction

Kaihua Mold specializes in the production of high-quality pallet molds, particularly skilled in manufacturing Double-deck Plastic Pallet Mould. In terms of production process, kaihua adopt two methods: integrated process and welding process. The welding process is further subdivided into grid structured plastic pallets and flat double-sided welding pallets to meet the needs of different application scenarios.

Kaihua Double-deck Plastic Pallet Moulds are known for their excellent temperature resistance, which can maintain stability in high temperature environments and function normally under low temperature conditions. Due to the main use of HDPE (high-density polyethylene) and PP (polypropylene) materials,Double-deck Plastic Pallet also exhibit excellent corrosion resistance. Therefore, the Double-deck Plastic Pallet produced by Kaihua are very suitable for various occasions such as factories, warehouses, and shipyards.

In addition to providing standard series double-layer plastic pallet molds, Kaihua is also committed to providing customized solutions to meet the unique needs of each customer. No matter what specific size, shape, or load capacity you need, kaihua mold professional team will work closely with you to design and manufacture personalized products that fully meet your requirements.

Kaihua always puts customer service and support first, ensuring that customers enjoy a high-quality experience throughout the entire cooperation process. If you are looking for a reliable and cost-effective logistics solution, Kaihua Mold's double-layer plastic pallets will be your ideal choice. With a strong commitment to quality, innovation, and service, kaihua can guarantee to provide you with the highest quality products and services on the market. Feel free to contact us anytime to learn more details and explore how to optimize your transportation and logistics operations, improve efficiency and profitability through our products.

2.Case Product Parameters

| Part Name | Double-deck Plastic Pallet |

| Mat'l Grade | PP |

| Part Weight(KG) | 12 |

| Product size(mm) | 1300X1100X150 |

| grain or electroplate | polishing |

| Demolding requirement | Gripper |

| wall stock(mm) | 3mm |

| mold weight(t) | 2.4 |

| Injection Machine(t) | 2700 |

| cavity number | 1 |

3.Production details

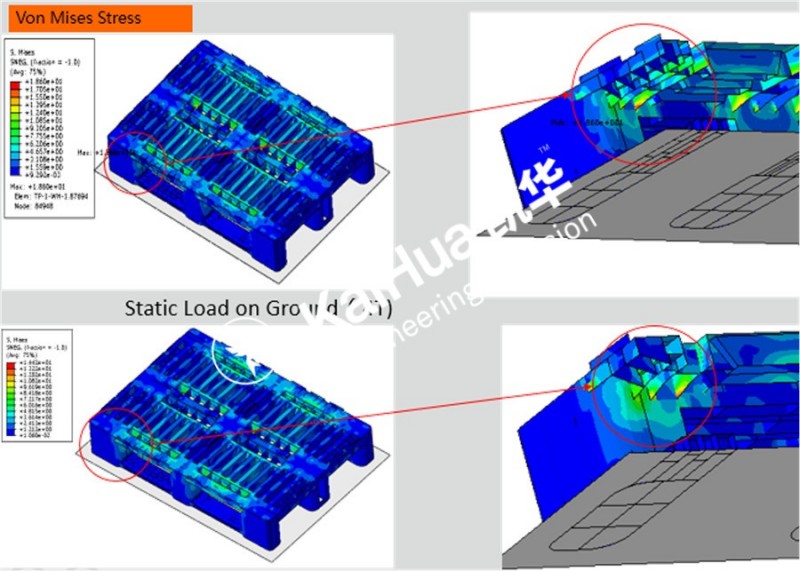

(1)Load-bearing analysis

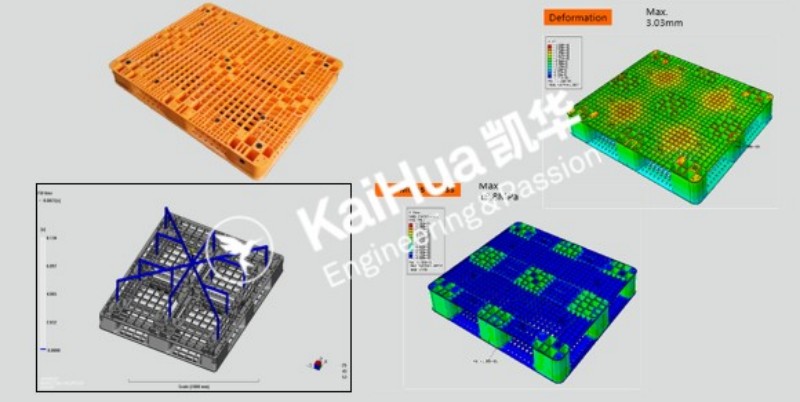

(2)3D image

(3)Pallet Mold Flow

4.Product feature and application

(1)Features:

●Four sided fork, suitable for flat ground, stacking, shelving, and forklift turnover of goods.

●Compared with single-sided pallets, the main function of Double-deck Plastic Pallet is to stack goods.

●Both sides can be used, with the same structure and specifications, and both sides can be interchanged for use

(2)Applications:

Kaihua Double-deck Plastic Pallet, crafted from thermoplastics like polyethylene (PE) and polypropylene (PP) along with performance-enhancing additives, are essential components in modern logistics, utilized alongside forklifts, storage racks, and other material handling equipment. Manufactured through processes such as injection and blow molding, Kaihua Double-deck Plastic Pallet excel in the efficient storage, loading, and handling of goods, serving as indispensable tools in contemporary warehousing systems. The shift towards plastic pallets reflects a move toward more sustainable practices, reducing reliance on timber and thus preserving forest resources. This transition aligns with the evolving needs of the logistics industry and addresses environmental concerns. Moreover, the food and pharmaceutical sectors increasingly favor Kaihua Double-deck Plastic Pallet due to their superior properties—resistance to corrosion, moisture, rust, insects, and mold—which meet stringent hygiene and safety standards. Additionally, their high load-bearing capacity and durability make Kaihua Double-deck Plastic Pallet suitable for a broad spectrum of applications across industries such as chemicals, textiles, and manufacturing, ensuring they remain a vital asset in today’s supply chains.

5.Prodect qualification

(1)Production process

●Closing the mold: Close the mold to ensure it is in place.

●Feeding: Add the dried plastic pellets into the hopper of the injection molding machine.

●Melting: Heating the injection molding machine to melt the plastic particles.

●Injection: Molten plastic is injected into a mold through an injection device.

●Pressure holding: Maintain a certain pressure in the mold to fully fill the mold with plastic.

●Cooling: Cooling and solidifying in the mold to shape the plastic.

●Demoulding: Open the mold and remove the plastic product.

(2)Product shipment and packaging photos

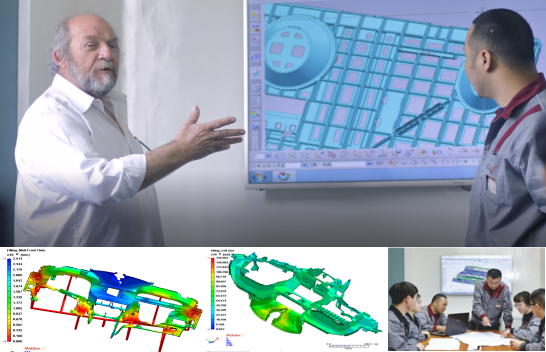

(3)Technical team

| Responsibilities of project members | Main responsibilities |

| project leader | Execute the entire project planning work arrangement, control quality, time, and cost |

| Project Engineer | Specific project site follow-up, handling, and control responsible person |

| salesman | Responsible for specific customer communication and logistics work |

| Design team leader | Responsible for reviewing and guiding product analysis and design, as well as mold structure design |

| Process Supervisor | Responsible for the development of mold production processes and production management |

| Project Director | Overall project planning, quality, time, cost control, and exception handling |

(4)Design review photos

(5)Photos of the Technical Department Meeting

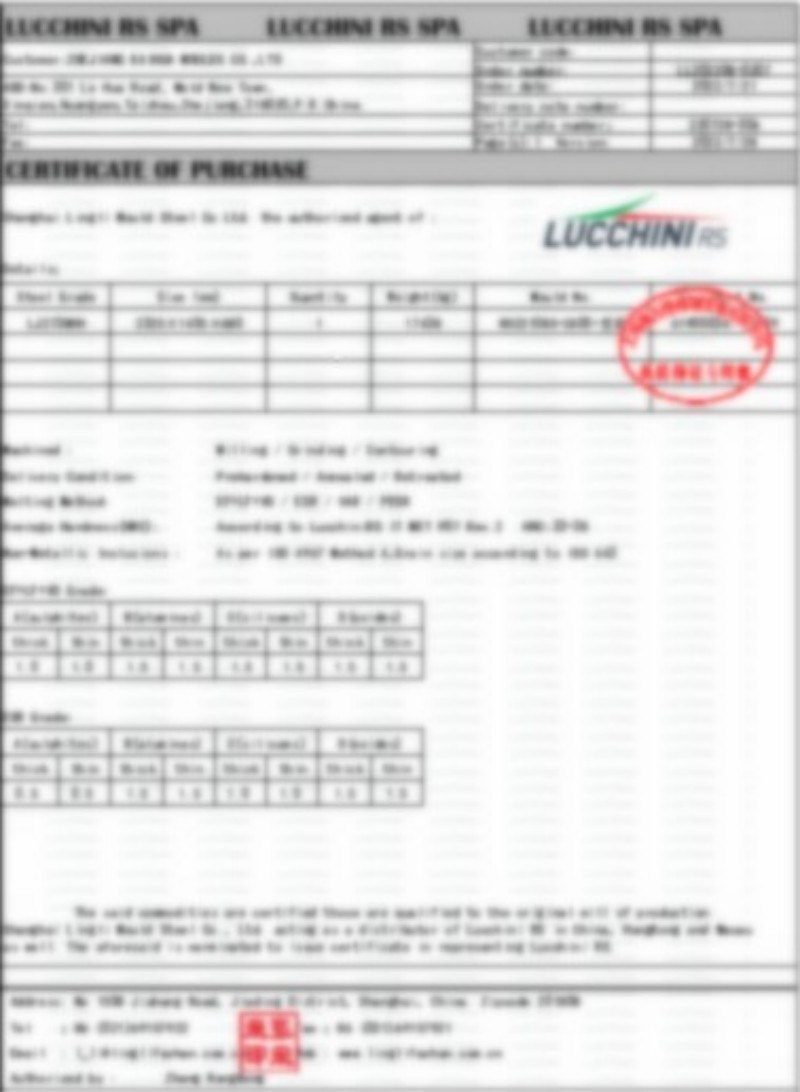

(6)Certificate

To learn more about Kaihua's certificates, please click here

6.Kaihua Mould Advantage

Strong Industrial Design

Kaihua Car Lamp Moulds from preliminary research, to engineering design, and then to interactive design, through structural case analysis, lightweight technology reserves, ergonomics research and development, and the practice of replacing steel with plastic, the structural design and appearance design are perfectly unified.

Kaihua has obtained more than 200 patents.

Through the mastery and flexible use of Mucell, Thin Wall, Gas-Assistance, Steel To Plastic and other lightweight technology, Stack Mould, Low-Pressure Injection Molding, In-Mold Degate , Free Spraying and other high efficiency innovation technology,

Provide customers with the best solutions.

|

Type |

Item |

Advantage |

Customer |

|

Leightweight |

Mucell |

Reduce cycle time,Enhance product accuracy,Remove sink marks,

Reduce clamping force and reduce product weight |

Mercedes-Benz, Volkswagen, |

|

Gas Assistance |

Reduce production cost, Improve appearance |

Land Rover, |

|

|

Thin Wall |

Reduce production cost i.e.raw material cost/Injection production cost by reducing product weight, Enhance product dimensional stability |

Geely, Nissan, Toyota |

|

|

Steel to Plastic |

Reduce product weight, Reduce production cost |

Land Rover, |

|

|

Efficiency |

Stack Mould |

Reduce mould cost and production cost |

Audi, IKEA |

|

Low Pressure |

Improve the qualified rate as well as cladding sense |

Audi, Volkswagen, |

|

|

In-Mold Degate |

Reduce labor cost,enhance production efficiency |

Ford, Land Rover, |

|

|

Free Spraying |

Reduce production cost, Environmentally friendly |

Renault, GM |

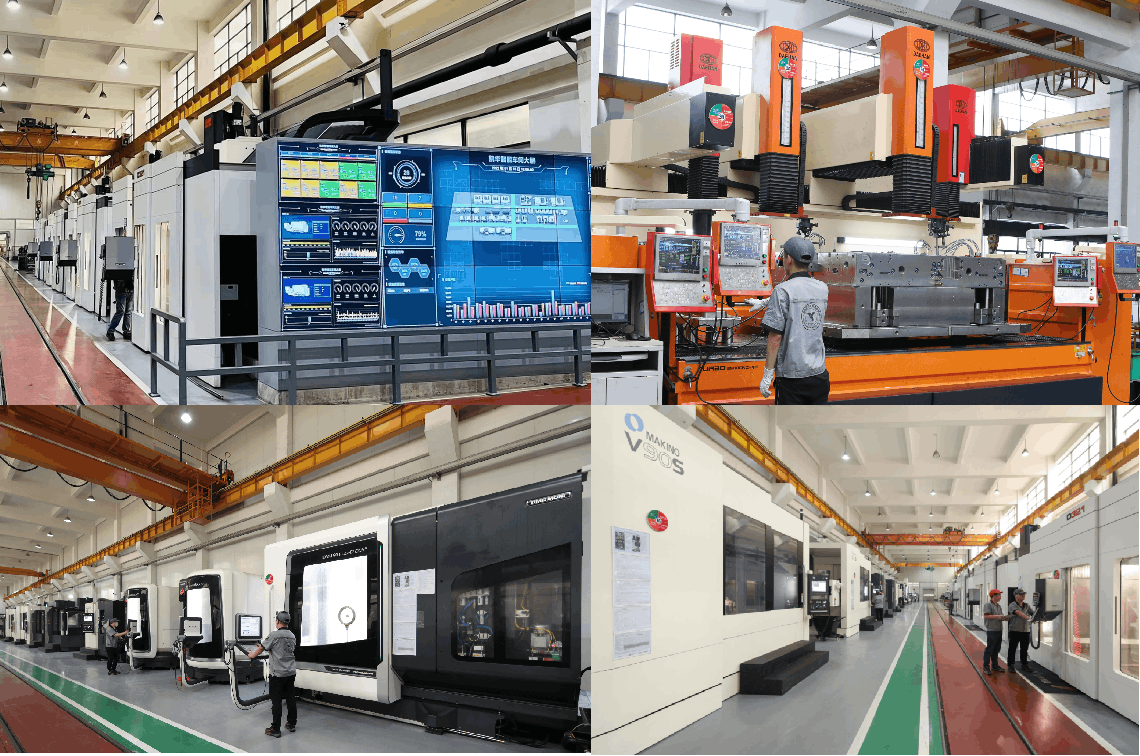

Machinery

Injection Production Equipment

■ Krauss Maffei 1600T Three-color Injection Molding Machine

1) Three-color injection molding, Core Back function, DIY main nozzle translation and other functions

2) It can be applied to two-color/three-color injection of headlights, chemical foamed door panels, injection-molded compression spoilers, etc.

■ YIZUMI 3300T Injection Molding Machine with 5 Axis Pickup

■ 17 Injection Molding Machines Covering 160T ~ 4500T

Five-Axis Linkage Mold Processing Equipment

■ FIDIA, Italy

■ MAKINO, Japan

■ DMU, German

■ 12 in Total

■ ……

High Precision Spark Machine

■ DAEHAN

■ MAKINO

■ 7 in Total

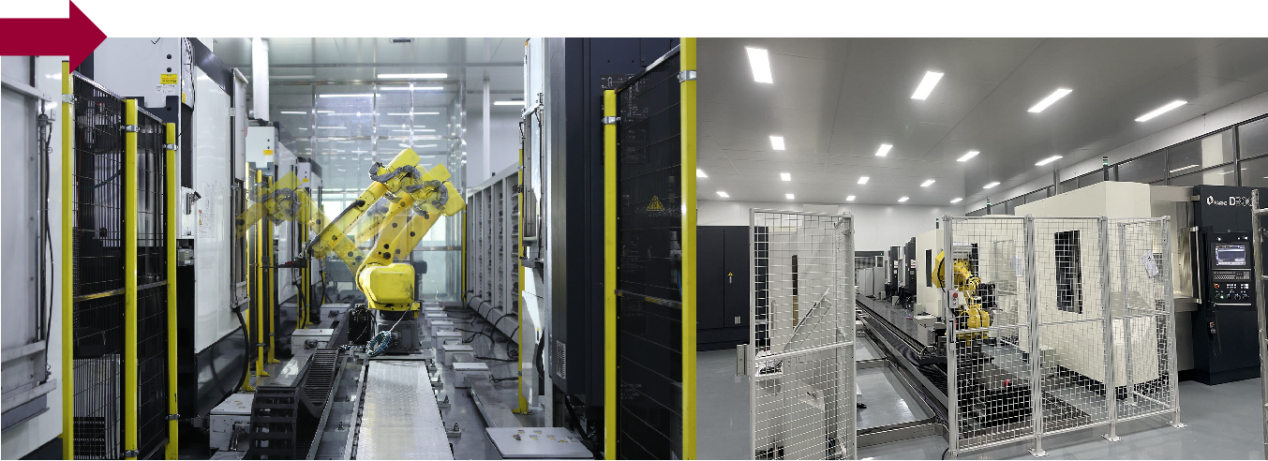

MAKINO Automation lines

|

Name |

Function |

Application |

Time Put Into Production |

Quantity |

| FIDIA GTS22 | Five-Axis Linkage CNC | Bumper & Dashboard Overall Processing | Oct. 2019 | 3 Units |

| FIDIA D321 | Five-Axis 3+2 CNC | Bumper & Dashboard Overall Processing | Jan. 2020 | 4 Units |

| MAKINO V90S | Five-Axis Linkage CNC | One-time Molding Of Large Top Block | Nov. 2019 | 2 Units |

| MAKINO F8 | Three Axis High Precision CNC | Medium Die And Part Finishing | Oct. 2019 | 2 Units |

| MAKINO A61nx | Horizontal Four-Axis High-Precision CNC | One-time Molding Of Large Top Block | Nov. 2019 | 1 Unit |

| DMU 90 | Five-Axis Linkage CNC | One-step Molding Of Medium-sized Top Block | Jan. 2020 | 1 Unit |

| DMU 75 | Five-Axis Linkage CNC | Small Top Block Is Formed At One Time | Oct. 2019 | 2 Units |

| DAEHAN Spark Machine |

Four-Head Precision Spark Machine | Dashboard & Bumper Edm Processing | Sep. 2019 | 2 Units |

| DAEHAN Spark Machine |

Double Head Precision Spark Machine | Dashboard & Bumper Edm Processing | Jul. 2019 | 3 Units |

| MAKINO Spark Machine |

Precision Spark Machine | Mirror Edm Processing Of Mesh & Electroplated Parts | Oct. 2019 | 2 Units |

| MAKINO Flexible Graphite Automatic Production Line | Precision Graphite Processing Machine | Graphite Electrode Processing | Oct. 2019 | 6 Units |

Integrated injection molding

From product research and development, mold manufacturing, to injection molding, mass production and assembly, the integration of mold injection molding is realized; the volume of injection molded parts can reach 4m², The molding cycle is short, and the surface quality is high, ensuring "fine molds" to produce "high-quality products".

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.