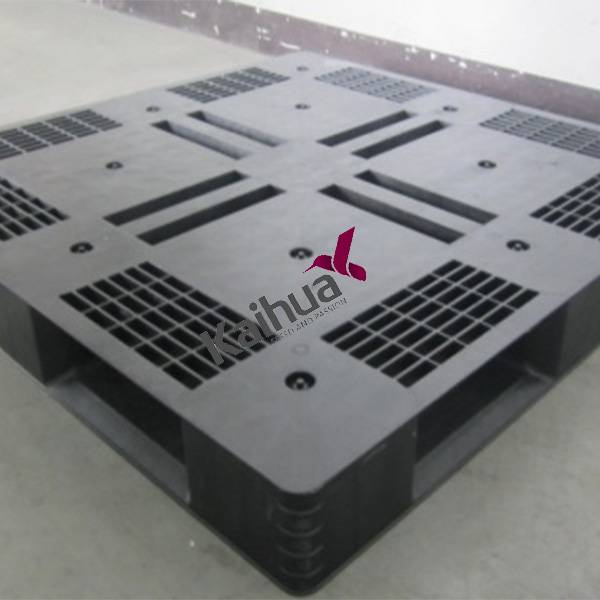

Double-deck Plastic Pallet of injection moulds products

1.Product Introduction

Kaihua excels in the manufacture of premium pallets, with a particular proficiency in crafting Double-deck Plastic Pallets. Kaihua production process encompasses two primary techniques: the integrated approach and the welding method, the latter of which is further tailored into grid-structured plastic pallets and flat, double-sided welded pallets to cater to diverse application requirements.

Renowned for their exceptional temperature resilience, Kaihua's Double-deck Plastic Pallets maintain stability in high-temperature environments and operate seamlessly in low-temperature conditions. Utilizing HDPE (high-density polyethylene) and PP (polypropylene) materials, these pallets also demonstrate robust corrosion resistance. Consequently, kaihua's Double-deck Plastic Pallet are ideal for various settings, including factories, warehouses, and shipyards.

Beyond offering standard double-layer plastic pallets, Kaihua is dedicated to providing customized solutions tailored to each customer's unique needs. Regardless of the specific size, shape, or load capacity you require, kaihua professional team collaborates closely with you to design and manufacture personalized products that perfectly align with your demands.

At Kaihua, customer service and support are paramount, ensuring a superior experience throughout our partnership. For those seeking a dependable and cost-effective logistics solution, Kaihua Mold's Double-deck Plastic Pallets stand as an exemplary choice. With an unwavering commitment to quality, innovation, and service, kaihua guarantee top-tier products and services in the market. Do not hesitate to reach out to us at any time for further details and to explore how our products can optimize your transportation and logistics operations, enhancing efficiency and profitability.

2.Case Product Parameters

| Part Name | Double-deck Plastic Pallet |

| Mat'l Grade | PP |

| Part Weight(KG) | 12 |

| Product size(mm) | 1300X1100X150 |

| grain or electroplate | polishing |

| Demolding requirement | Gripper |

| wall stock(mm) | 3mm |

| mold weight(t) | 2.4 |

| Injection Machine(t) | 2700 |

| cavity number | 1 |

3.Production details

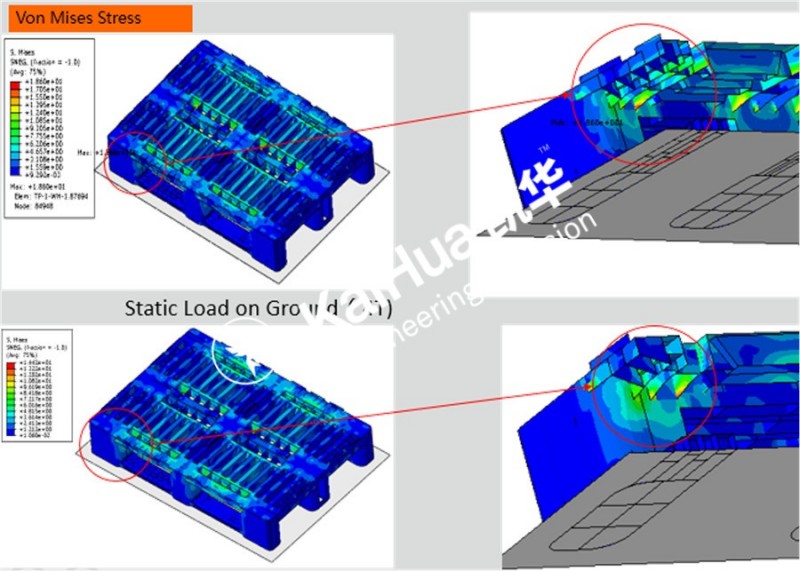

(1)Load-bearing analysis

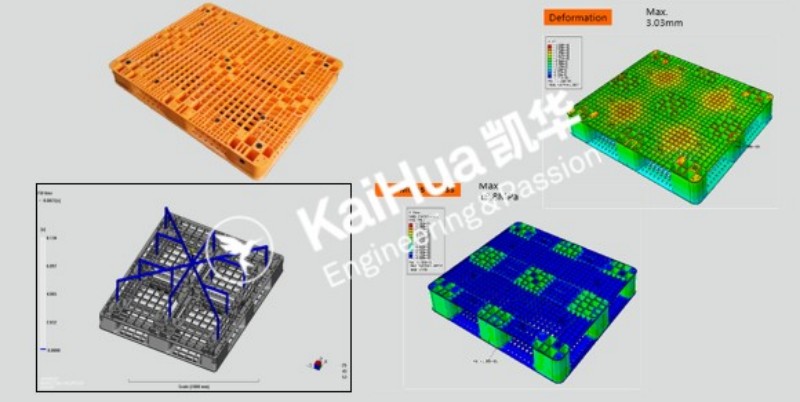

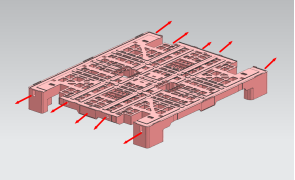

(2)3D image

(3)Pallet Mold Flow

4.Product feature and application

●The temperature resistance range is usually -25 ℃ to+50 ℃ (some high-quality materials such as polypropylene Double-deck Plastic Pallet can be used normally within the temperature range of -30 ℃ to 65 ℃, but should avoid direct sunlight exposure and proximity to heat sources).

●The process application is an automated line. Manual labor only requires loading the processed iron material onto the fixture and feeding it; All other loading, processing, and unloading tasks are completed by robots, and the program is inputted through programming. Reduce labor costs, improve accuracy, and reduce production cycles by half.

5.Prodect qualification

(1)Production process

●Mold Closure: Secure and verify the closure of the mold to ensure its proper alignment.

●Material Loading: Place the dried plastic pellets into the injection molding machine's feed hopper.

●Thermal Treatment: Increase the temperature within the injection molding system to liquefy the plastic pellets.

●Material Injection: Use an injection unit to push the now-melted plastic into the mold cavity.

●Pressure Maintenance: Apply and sustain pressure within the mold to ensure it is thoroughly filled with plastic.

●Cooling Process: Allow the plastic to cool and harden inside the mold, defining its final form.

●Product Removal: Release the mold and extract the newly formed plastic item.

(2)Product shipment and packaging photos

(3)Technical team

| Responsibilities of project members | Main responsibilities |

| project leader | Execute the entire project planning work arrangement, control quality, time, and cost |

| Project Engineer | Specific project site follow-up, handling, and control responsible person |

| salesman | Responsible for specific customer communication and logistics work |

| Design team leader | Responsible for reviewing and guiding product analysis and design, as well as mold structure design |

| Process Supervisor | Responsible for the development of mold production processes and production management |

| Project Director | Overall project planning, quality, time, cost control, and exception handling |

(4)Design review photos

(5)Photos of the Technical Department Meeting

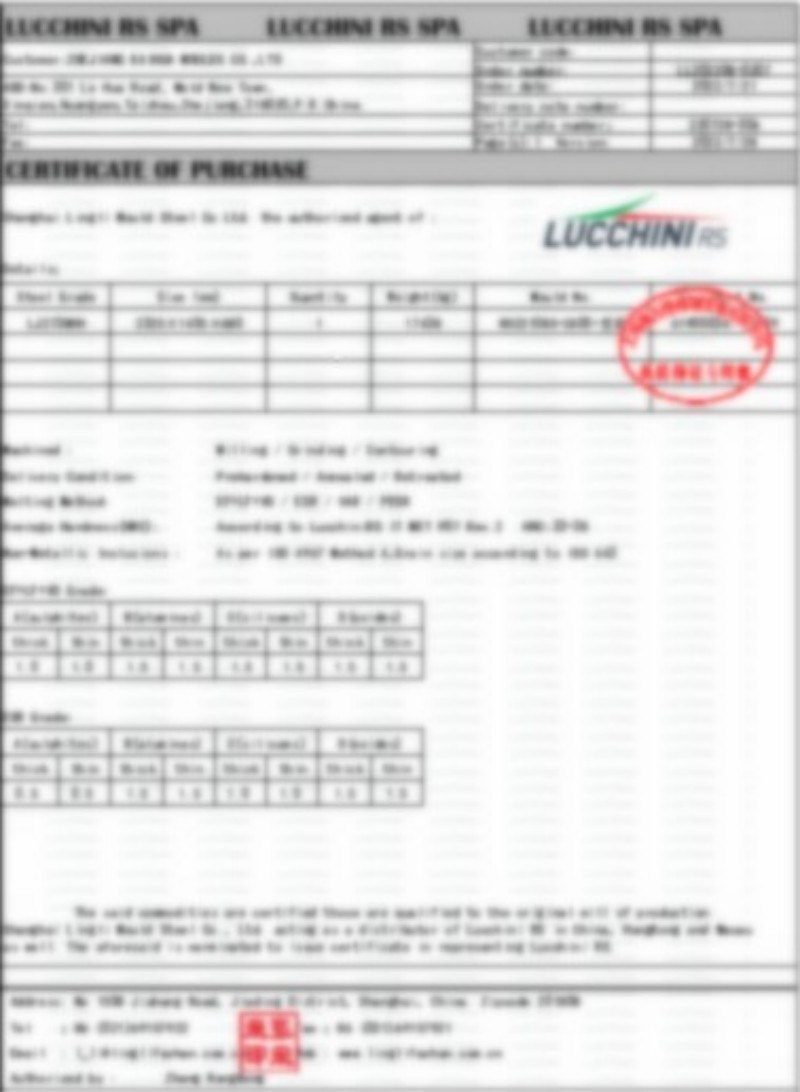

(6)Certificate

To learn more about Kaihua's certificates, please click here

6.Kaihua Mould Advantage

Click here,gain a deeper understanding of Kaihua's advantages,experience our professional strength and quality assurance!

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.