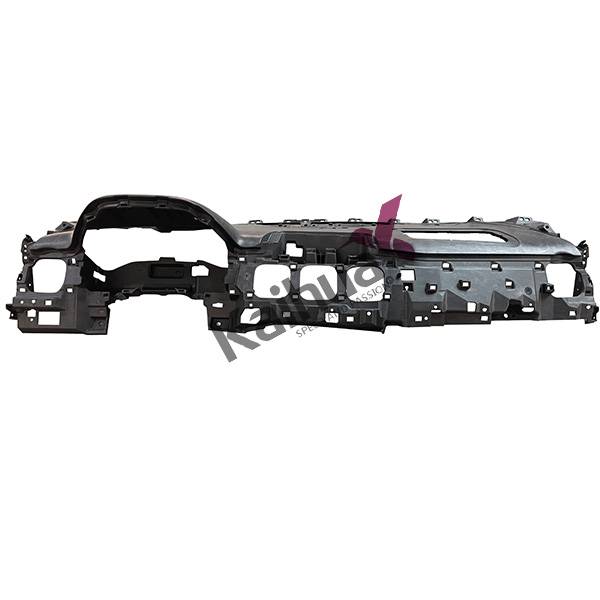

High definition Low Run Injection Molding - Automobile instrument panel mould – KAIHUA

High definition Low Run Injection Molding - Automobile instrument panel mould – KAIHUA Detail:

The most important part of the automobile mold is the cover mold. This type of die is mainly a cold die. In a broad sense, “automobile mold” is the general term for the molds used to manufacture all parts of automobiles. For example, stamping molds, injection molds, forging molds, casting wax molds, glass molds, etc.

The stamping parts on the car body are roughly divided into cover parts, beam parts and general stamping parts. The stamping parts that can clearly express the characteristics of the car’s image are the car cover parts. Therefore, the more specific automobile mold can be said to be the “automotive cover stamping mold.” Referred to as automotive panel die. For example, the front door outer panel trimming die, the front door inner panel punching die, etc., of course, not only on the car body, there are stamping parts. All stamping dies on automobiles are called “automotive stamping dies”. In summary:

Automobile mold is the general name of molds used to manufacture all parts of automobiles.

Automobile stamping dies are used to punch all stamping parts on automobiles.

Auto body stamping die is a die for punching all stamping parts on auto body.

Auto cover stamping die is a die for punching all cover parts on auto body.

Now when we talk about automobile molds in this sector, it seems to refer to automobile cover die. In order not to be confused with automobile die in a broad sense, it is best to use automobile cover die instead of auto die when posting. There are many forms of stamping dies, and the dies are also classified according to the nature of work, mold structure, and mold materials.

Automotive division annually make about 1200 moulds on average, especially good at large and medium-sized interior mold, classic case such as foaming dashboard mould for ford, Volkswagen, Benz, the Great Wall and stc., stack mould of door panel for audi, gas-assisted door panel mould, highlights non-mark grille mould, low-pressure molding column mould for jaguar

Sanmen base covers an area of 36,000 square meters with over 350 employees, and produces over 600 sets of molds annually. It is specialized in plastic injection moulds for automobile parts like automobile bumpers, fences, lamps and other exteriors system parts; automobile dashboard, door panel and other interior decoration system parts; wind frame, wind blade, flume and other cooling system parts. It mainly provide moulds and services to well-know automobile brands such as GM, FORD, VW, BMW, BENZ, Peugeot, RENAULT, Magna, FIAT, VOLVO, NISSAN, TOYOTA, and well-known automobile enterprises such as IAC, PO, Faurecia, Viston, BOSCH, BEHR, Valeo and Denso. 70% of the moulds are exported to more than 30 countries or regions such as Europe, North America, South America, Asia and etc.

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for High definition Low Run Injection Molding - Automobile instrument panel mould – KAIHUA , The product will supply to all over the world, such as: Malaysia, Morocco, Lebanon, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!