High Performance Rim Injection Molding - Household Division – KAIHUA

High Performance Rim Injection Molding - Household Division – KAIHUA Detail:

Household division has an annual production capacity of 300-500 sets moulds, with fast delivery time and competitive cost. Most of the moulds are made for table and chair, storage box, cabinet, laundry basket, kids toys etc. By knowing how to reduce cycle time, how to reduce weight and how to form nice and strong products, our moulds can bring great value to our customers.

our advantages

High Quality (Mold & Product Quality)

On-time delivery (Approval Sample & Mould Delivery)

Cost Control (Direct & Indirect Cost)

Best Service (Service to Customer, Employee & Supplier)

System— U8 ERP management system

Routine—Project Engineering Control

Document—ISO9001-2008

Standardization—Performance Assessment System

Huangyan Headquarters

With an annual mould production capacity beyond 1,600 sets, more than 650 employees, and covering an area of 42,000 square meters, Huangyan base is divided into four different divisions which include Logistic division, Medical division, Automotive division, Household division and Home appliance division.

Sanmen Plant

With an annual mould production capacity beyond 900 sets, more than 500 employees, and covering an area of 36,000 square meters, Sanmen base has specialized in manufacturing automotive moulds for exterior system, interior system and cooling system.

Manufacturing team are consist of machining workshop,assembly workshop,spotting workshop, polish workshop andinjection workshop.Among all manufacturing team, there are more than 30% technicians shom have been awarded as intermediate orsenior technicians Moreover, technicians whom have more than 10 years experience take up more than 20%.

Machining team: consist of rough machining, semi-precision machining, precision machining, 5-axis machining center, programming and other groups. Entire workshop is covering by air conditioner. All processing are under the control of ERP.

Assembly team: all mould makers can focus on making the moulds which they are good at. The average experience of mould maker is over 20 years.

Spotting team: With 100T-500T spotting machine, the operators fully understand the principle of spotting, how to control spotting.

Polishing team: with deep connection to assembly team, they know how to achieve the polishing requirements of different types of products, even mirror polish level.

Injection team: we have injection machines available from 120T-3300T, with robot, magnet clamping and hydraulic clamping. The operators can test in the conditions which are close to the actual production conditions and even exceed the actual production conditions, to let our customer have good references.

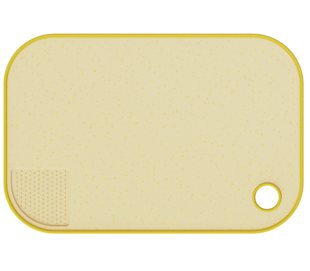

Product detail pictures:

Related Product Guide:

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for High Performance Rim Injection Molding - Household Division – KAIHUA , The product will supply to all over the world, such as: Croatia, Congo, Saudi Arabia, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.