Hot Runner

1.Product Introduction

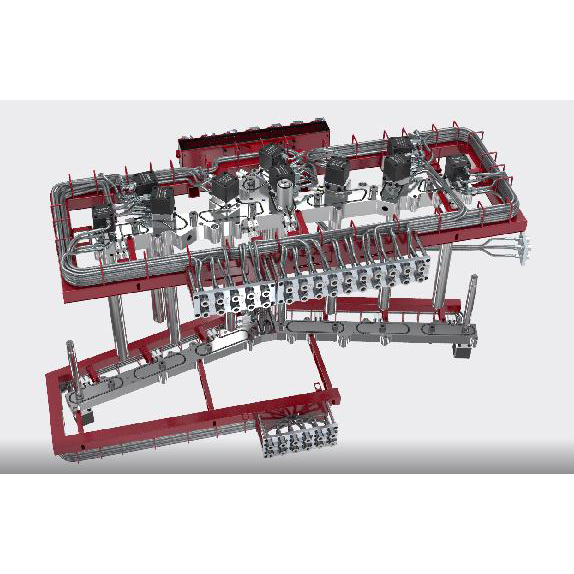

Hot Runner Systems from Kaihua Mold: The Economical Choice for Mass-Produced Plastic Parts

When it comes to mass production of plastic parts, such as everyday items and consumer goods, hot runner systems are often the most efficient and economical choice. And when it comes to reliable, high-quality hot runner systems, Kaihua Mold is a leading name in the industry.

Hot runner systems are designed to allow melted plastic to flow directly into the mold cavity, eliminating the need for additional waste plastic. This not only reduces material costs, but also makes the process more environmentally friendly. And with Kaihua Mold's innovative hot runner technology, you can expect even greater precision and accuracy in your production process.

Kaihua Mold offers a wide range of hot runner systems to suit any application, with options for both high and low volume production. Plus, our experienced team of engineers is always on hand to provide expert guidance and support throughout the process.

So whether you're looking to mass-produce plastic components for consumer goods or industrial applications, Kaihua Mold can help you achieve your goals with unparalleled efficiency and quality. Contact us today to learn more about our hot runner systems and how we can help take your production process to the next level.

2.Advantages

The cost of raw materials is low, and there is no waste recycling, saving runner waste and grinding recycling costs.

Shorten filling time, cooling time, mold opening and closing stroke and molding cycle.

The gate part can be automatically separated, saving the time of taking out the runner.

The molding temperature and pressure are low, and the stress of the finished product is small.

Precise control of gate temperature for balanced multi-cavity filling.

Fully automatic molding.

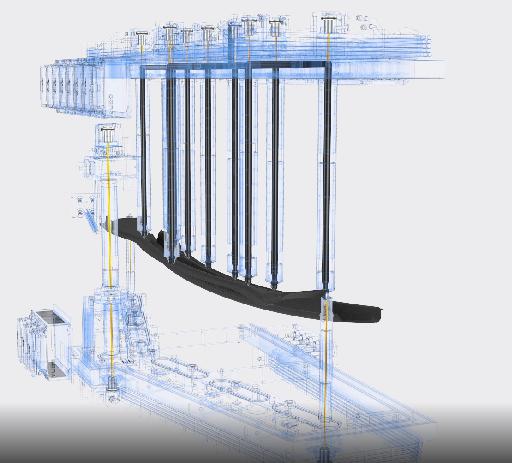

3.Detail

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

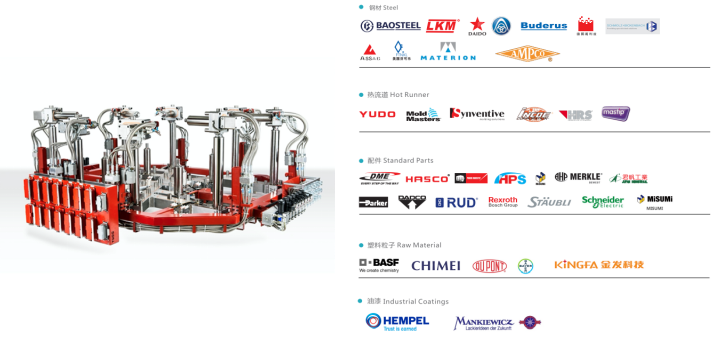

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.