Hot Sale for OEM Plastic Injection Mould for Car Spare Parts Auto Bumper

Adhering to your principle of “quality, assistance, performance and growth”, we have now gained trusts and praises from domestic and international customer for Hot Sale for OEM Plastic Injection Mould for Car Spare Parts Auto Bumper, Presently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Adhering to your principle of “quality, assistance, performance and growth”, we have now gained trusts and praises from domestic and international customer for China Injection Mold and Automotive Parts, We welcome you to visit our company, factory and our showroom displayed various solutions that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to supply you the best service. If you will need more information, remember to do not hesitate to contact us by E-mail or telephone.

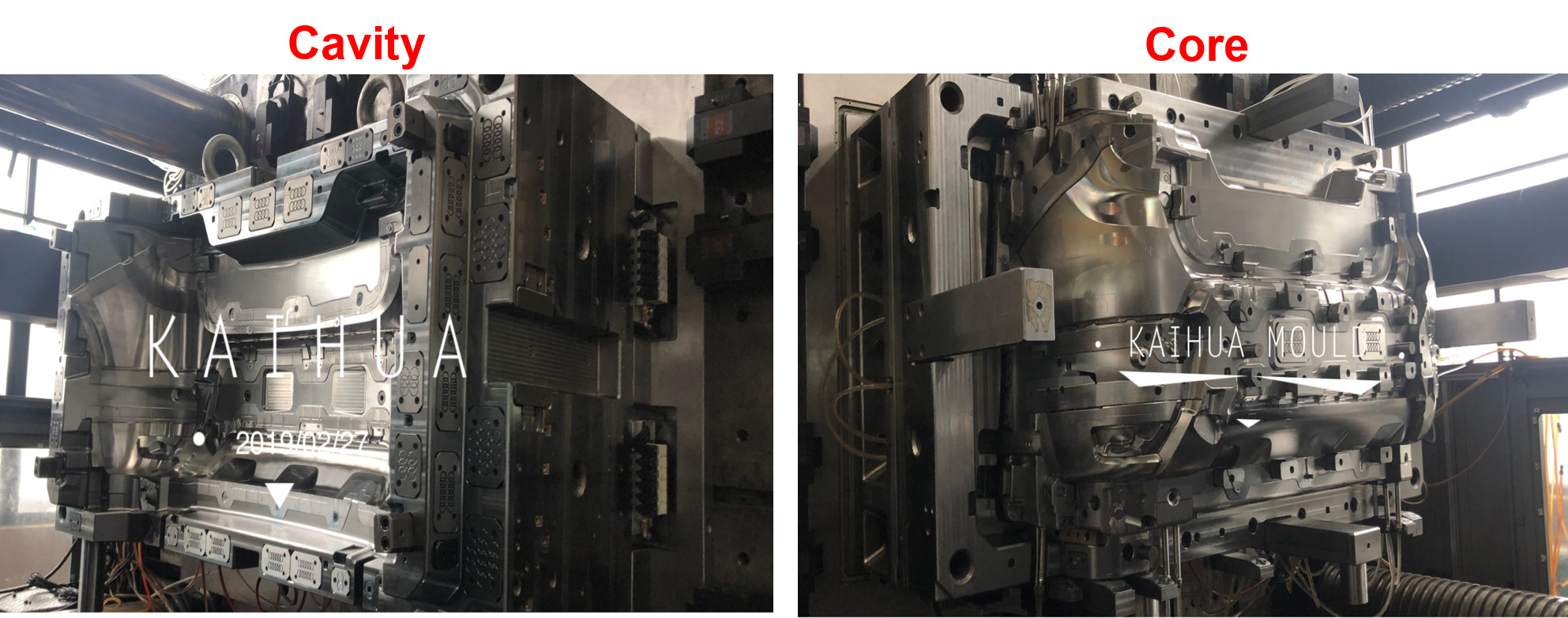

1.Product Introduction

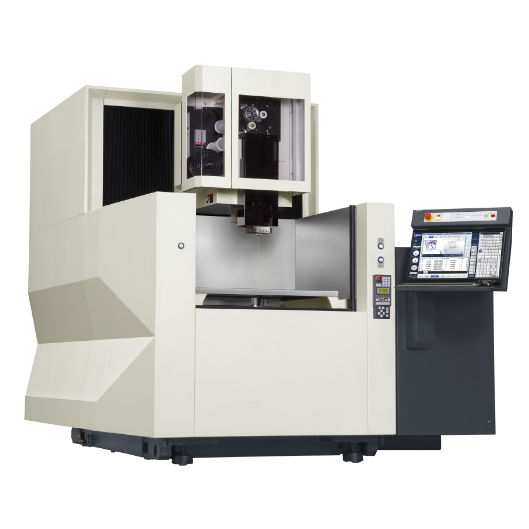

We can provide customers with the best solutions for Automotive Plastic Injection Molding with One Mold Two Cavities for Car Bumper.

Kaihua Service include: Product Design, Mold Design, Mold Making, Products Research & Development & Produce, Provide Processing Injection Molding For Tier 1.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | P20, 718, 8407, Nak80, H13, S136, DIN 1.2738, DINt |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc, or your requirement |

| Shaping Mode: | Plastic Injection Mould |

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Quote | According to Samples, Drawing and Specific Require |

| Production Capacity | 2400 Sets/Year |

| Design Software | CATIA, UG |

3.Product Feature and Application

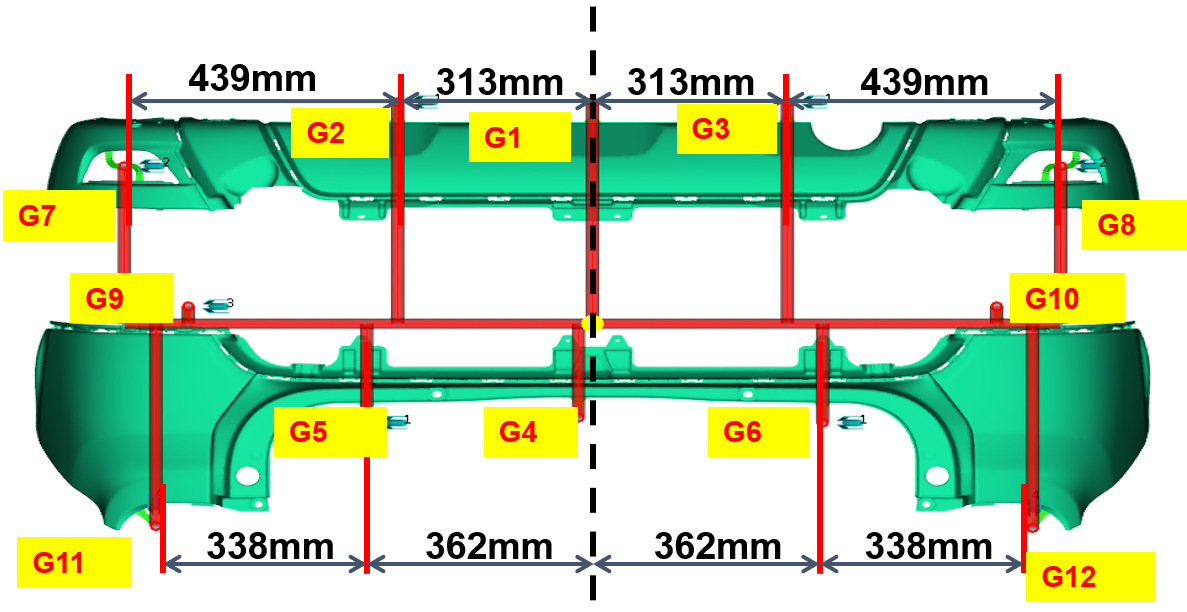

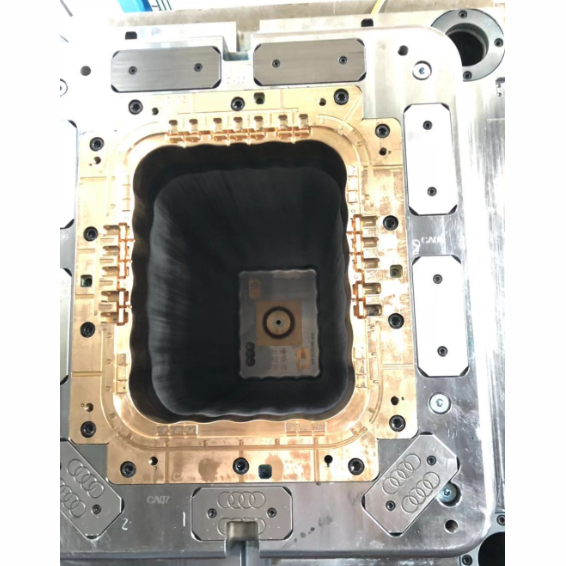

Technical Features :one mold with two cavities

1. Gate (product + hot nozzle)

2. Simulated fill time (About 5.2s)

Hot runner must be controlled separately, not shared, easy to maintain pressure control, product size adjustment.

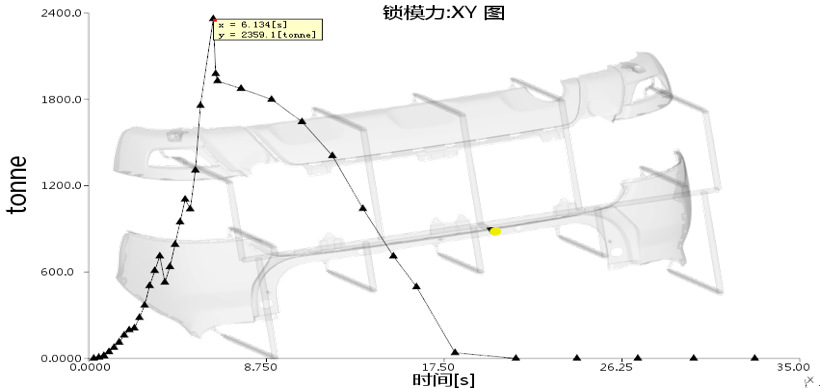

3. Clamp force

Projection area towards mold open direction is 6712mm^2, the Max. cavity pressure around 46.93 Mpa during fill time, clamp force needs 2359.10tonne during fill time and 2359.10tonne during cycle time, it would be better to increase 20% safety index regarding the actual situation.

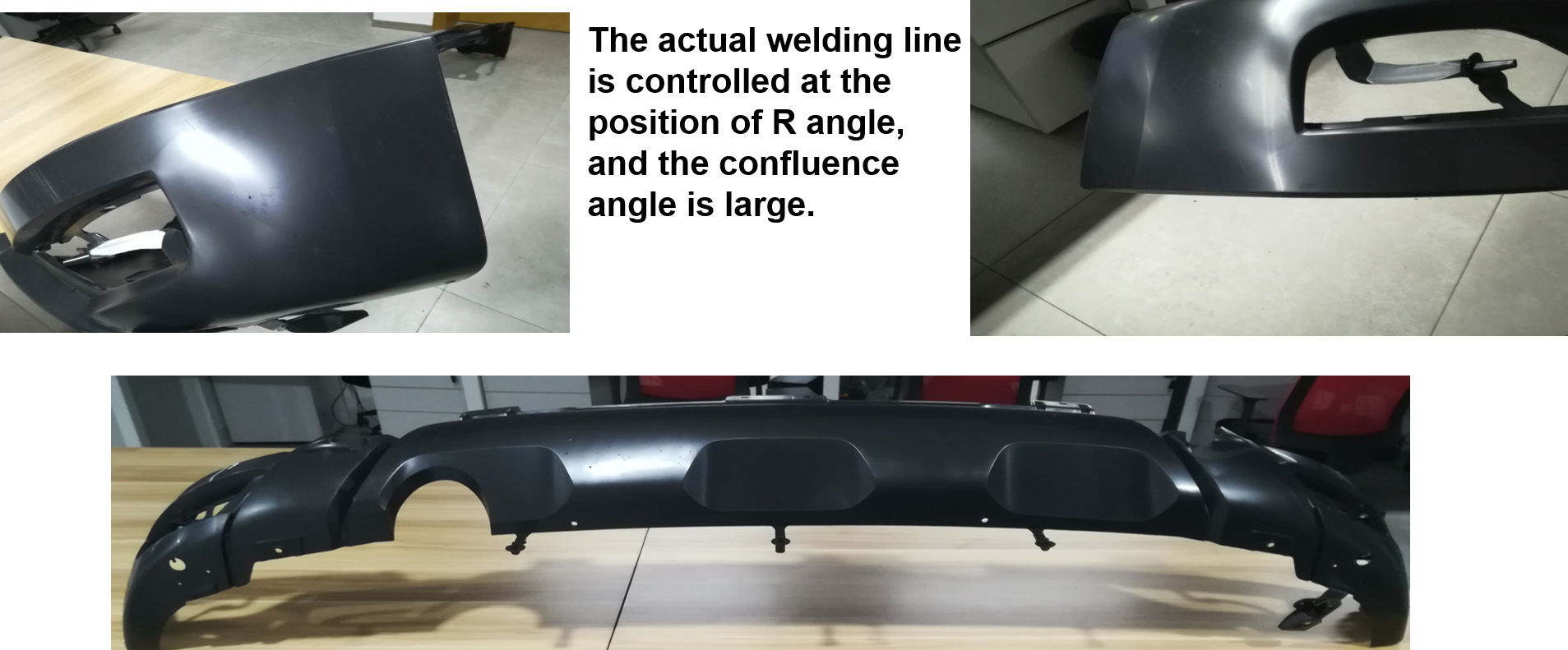

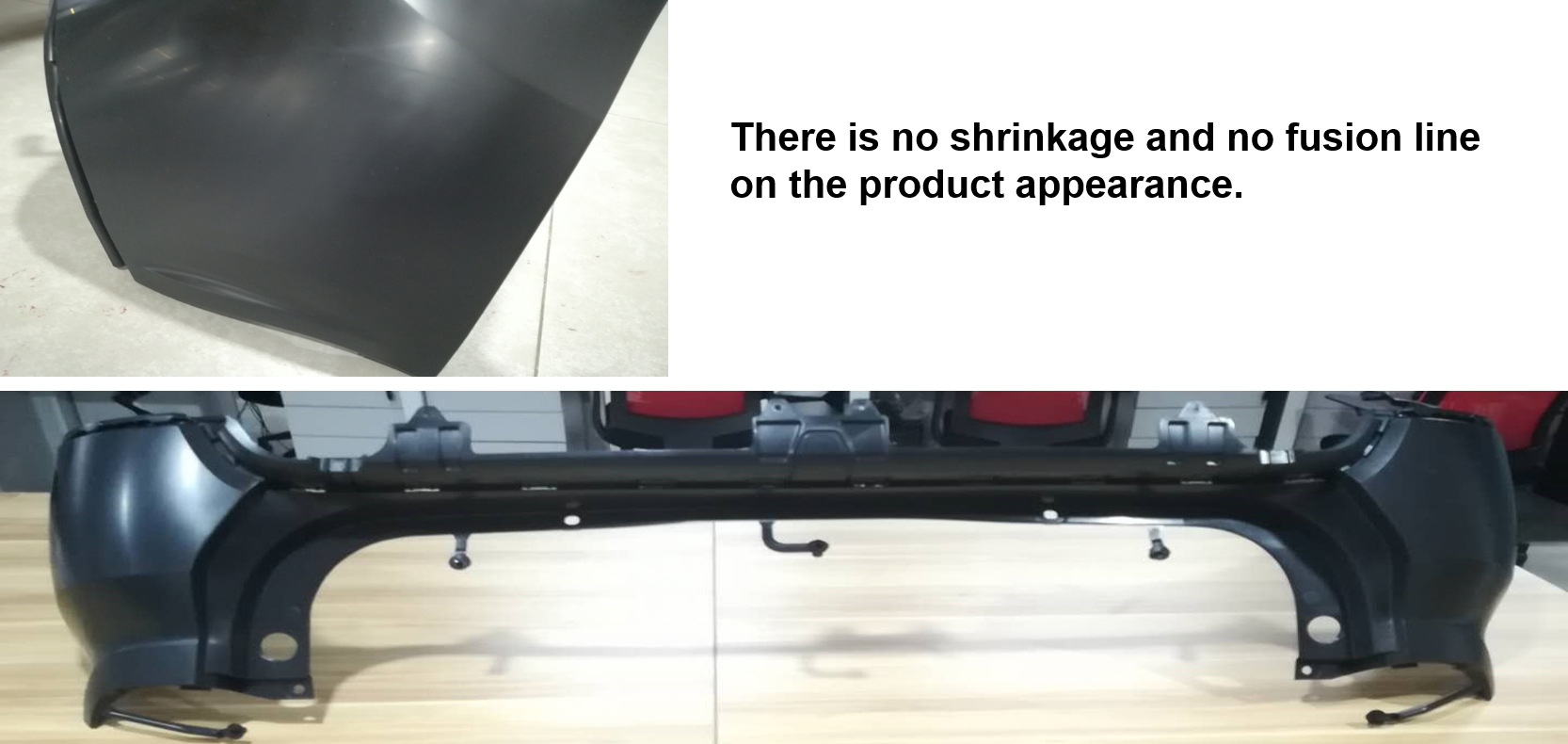

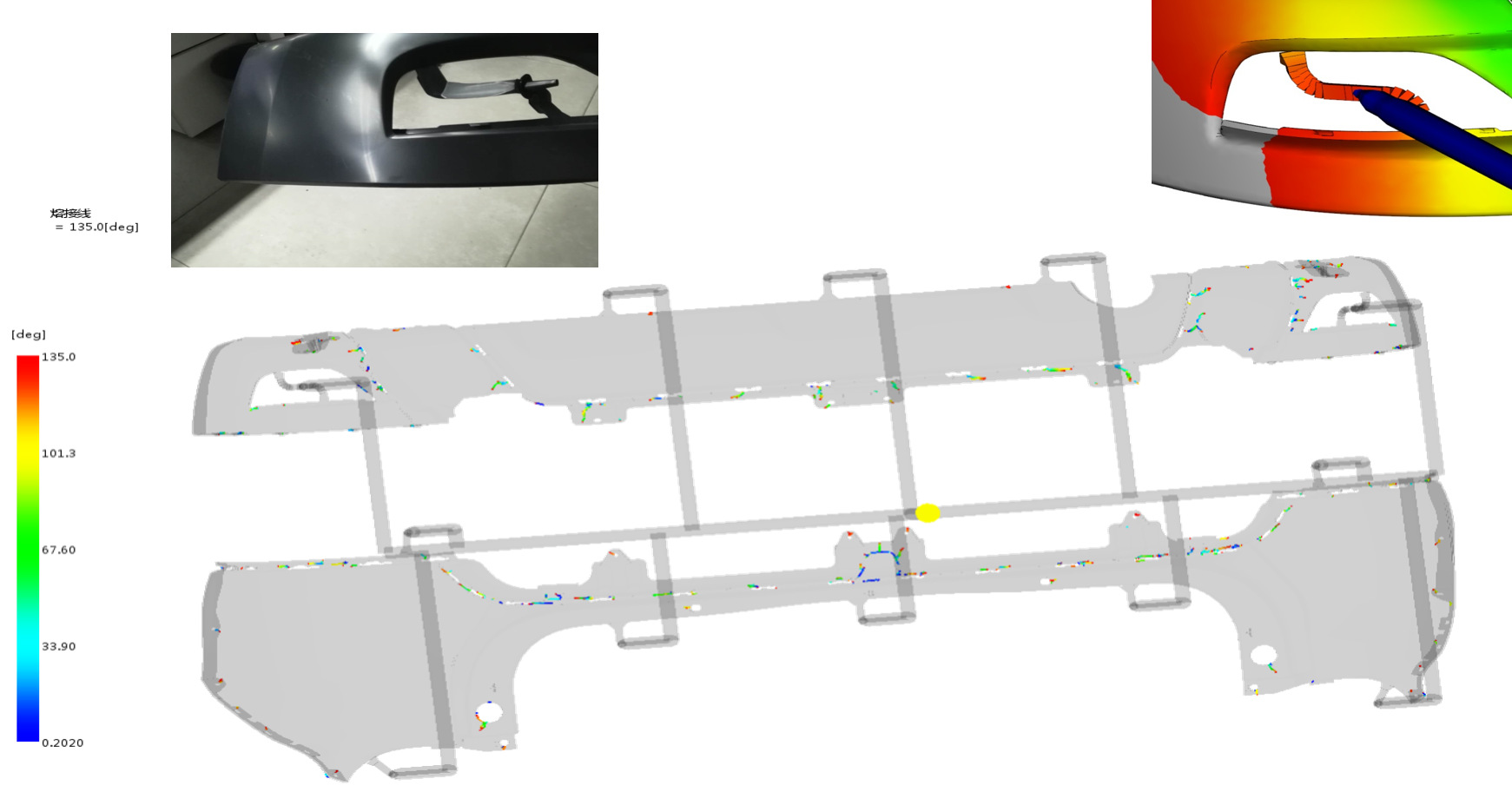

4.Welding line

4.Welding line

The welding line position of the product surface is shown in figure.

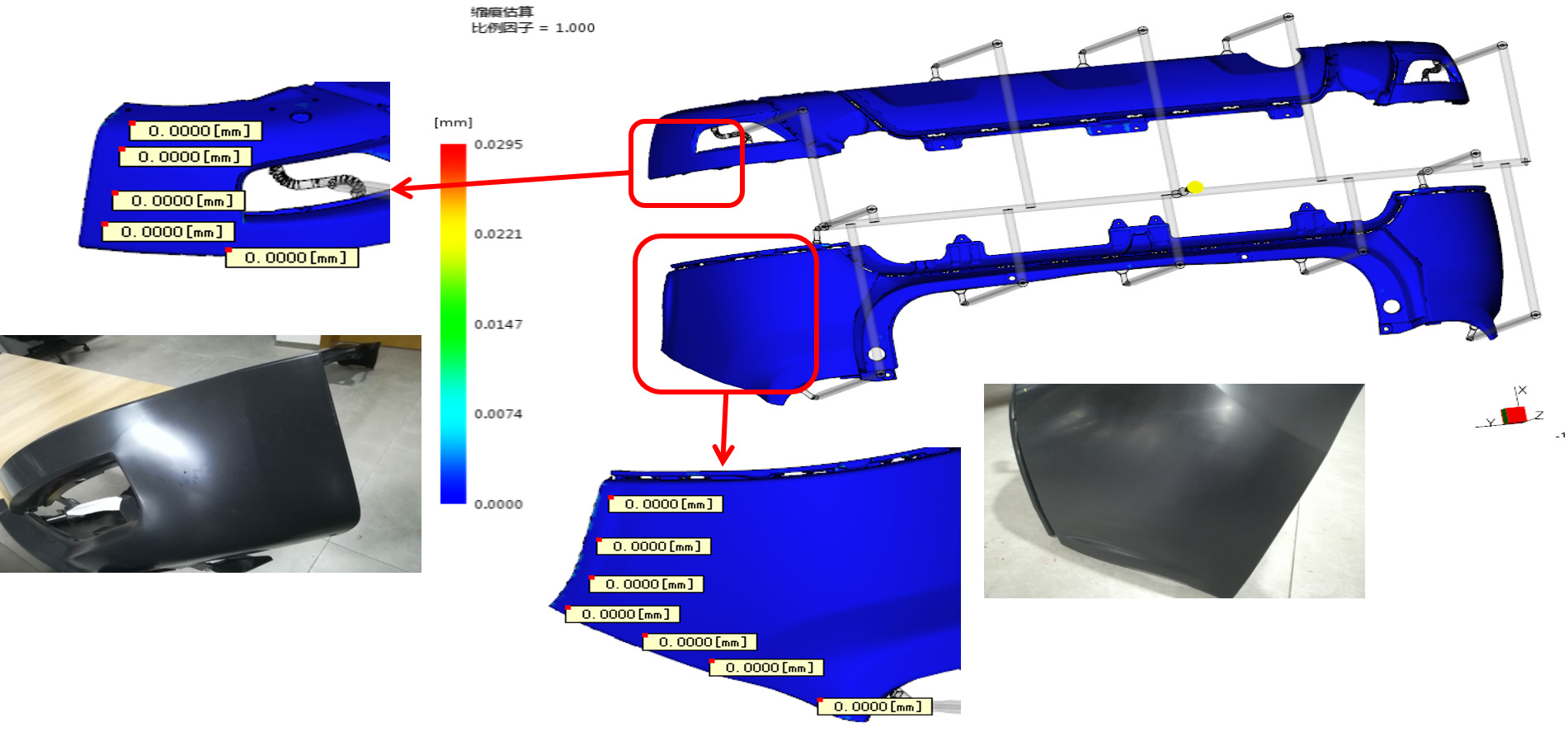

5.Shrinkage

5.Shrinkage

The test mold no obvious shrinkage marks on appearance of the product, which is consistent with the analysis.

6.Test mold sample

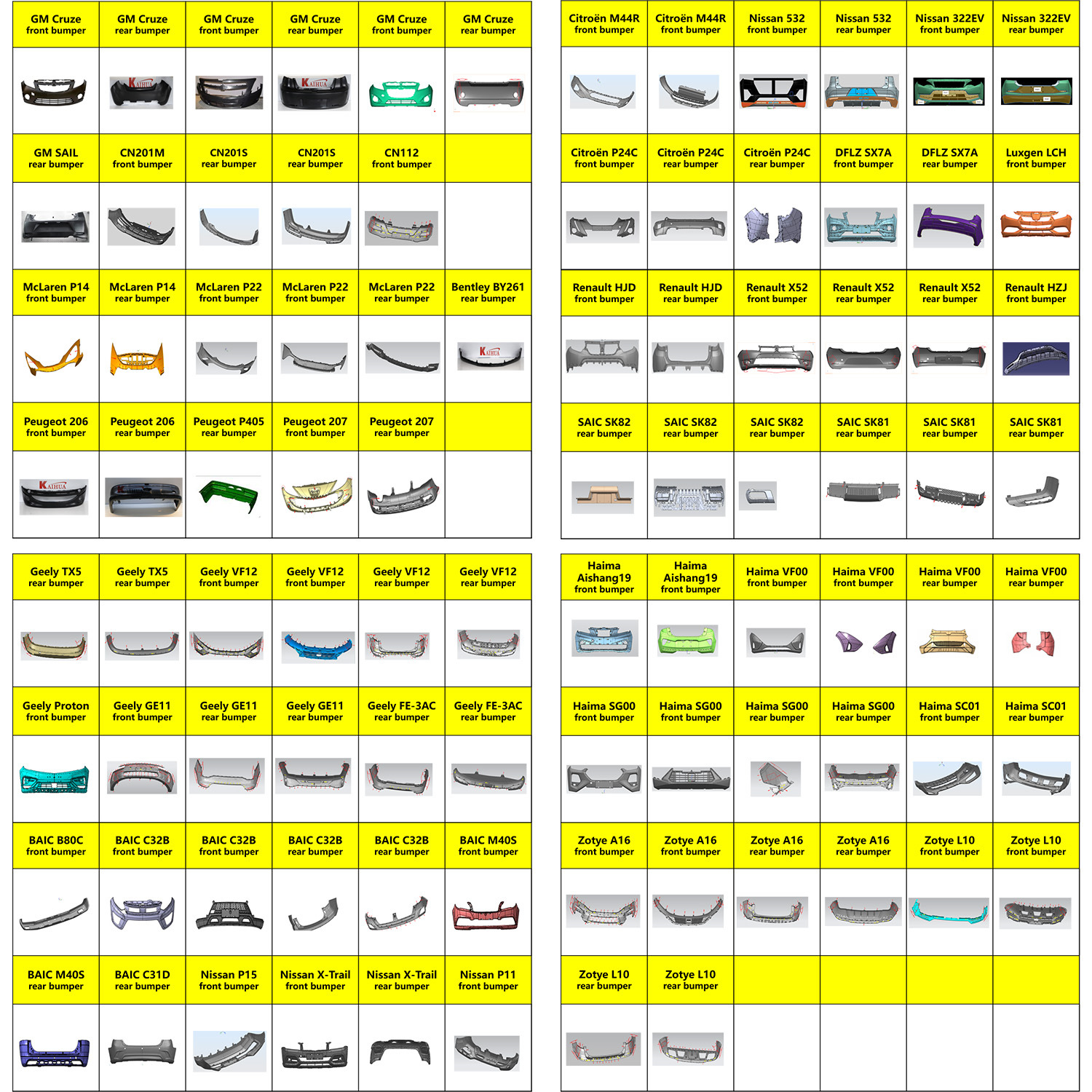

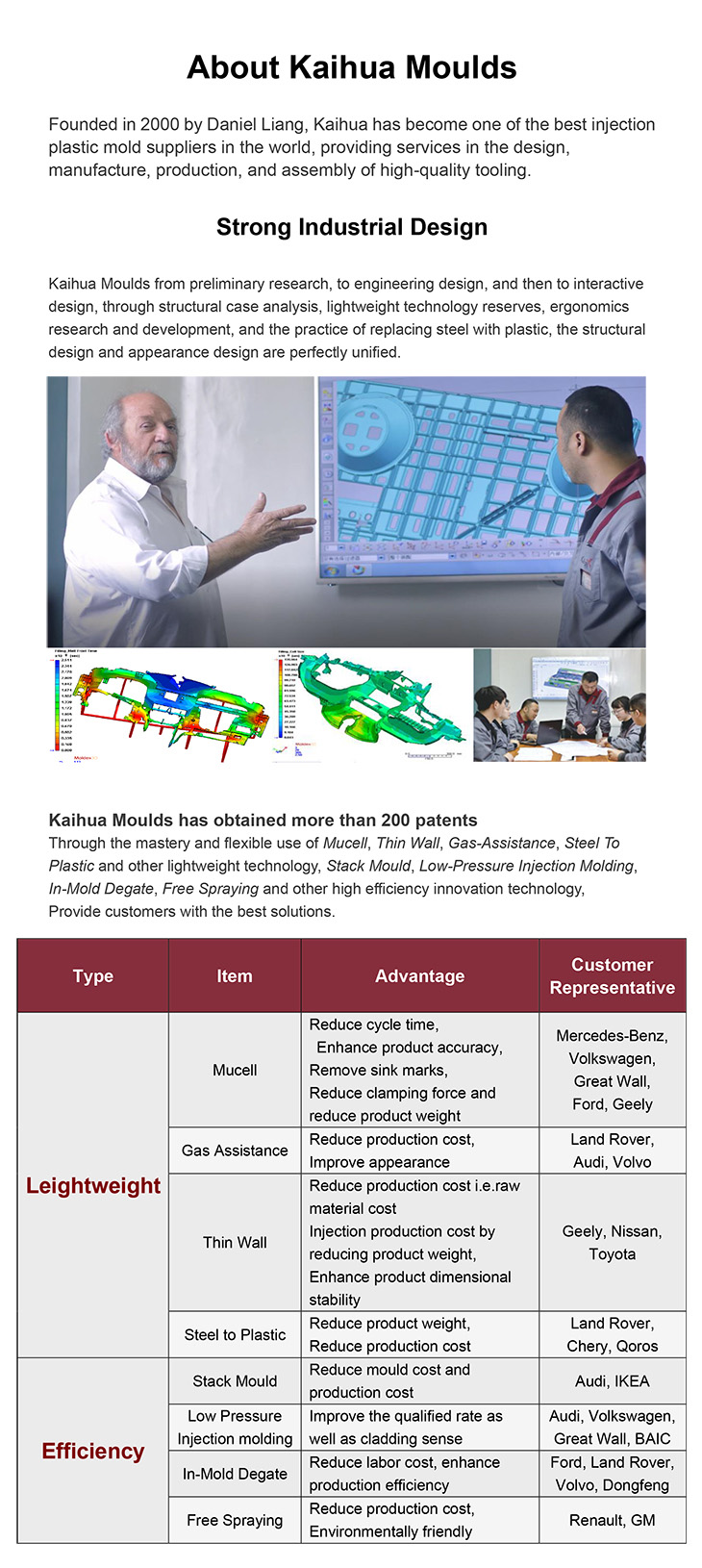

4. Cooperation Cases

Adhering to your principle of “quality, assistance, performance and growth”, we have now gained trusts and praises from domestic and international customer for Hot Sale for OEM Plastic Injection Mould for Car Spare Parts Auto Bumper, Presently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Hot Sale for China Injection Mold and Automotive Parts, We welcome you to visit our company, factory and our showroom displayed various solutions that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to supply you the best service. If you will need more information, remember to do not hesitate to contact us by E-mail or telephone.