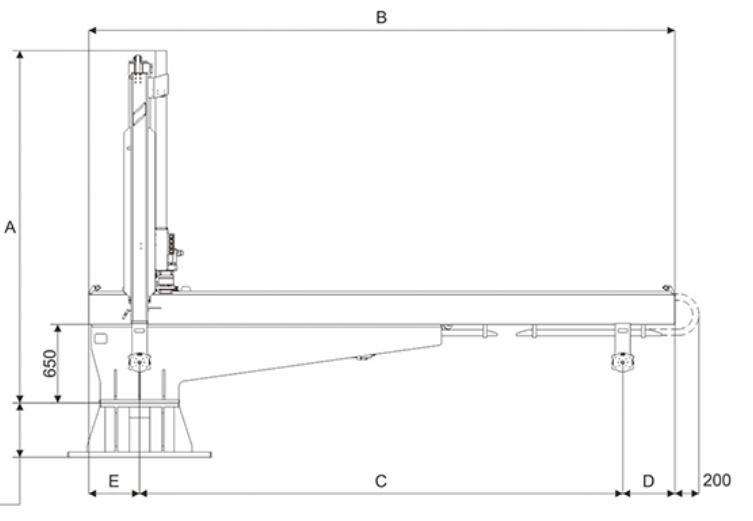

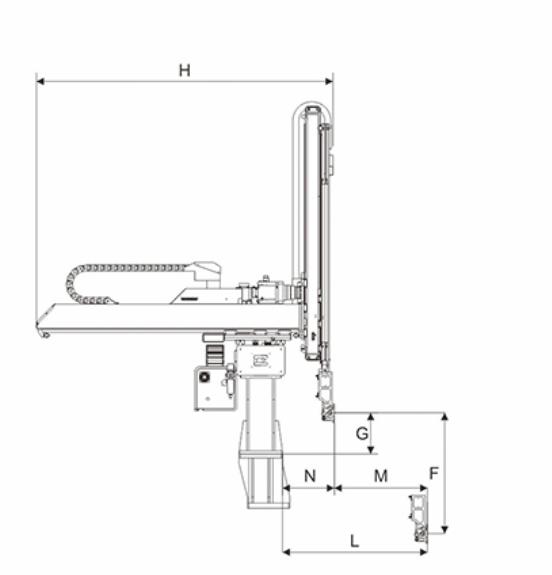

I.M.M.1300-2400T Servo Robot

1. Product Introduction

The I.M.M.1300-2400T Servo Robot by Kaihua Mold is the ultimate solution for all your industrial needs. This Servo Driven Robot is powered by state-of-the-art imported AC servo motors, ensuring precision and efficiency at all times. Its smart design utilizes light-weight and high-rigid aluminum alloy structure beams, which not only enables fast fetching and smooth actions, but also offers long service life and low vibration for maximum productivity.

The I.M.M.1300-2400T Servo Robot can efficiently perform a wide range of actions with ease, including arrangement, stacking, quality inspection, and embedding among others. With its ability to execute all kinds of special actions, your industrial process can become more seamless and quick, saving you precious time and resources.

Kaihua Mold's commitment to excellence is evident in the I.M.M.1300-2400T Servo Robot, which is built to meet the highest standards of quality and efficiency. Its precise and accurate movements were designed to cater to the demands of today's fast-paced industrial processes. The Servo Driven Robot's performance is unmatched, making it the ideal choice for various industries that require precise and efficient automation.

In conclusion, the I.M.M.1300-2400T Servo Robot by Kaihua Mold is the epitome of professional, precise, and high-quality design. It is the ultimate solution to make your industrial process more efficient, reliable, and productive. Its advanced capabilities, combined with Kaihua Mold's commitment to excellence, make this Servo Driven Robot the perfect choice for your industrial automation needs.

2.Advantages

· Aesthetic

This Five Axes Servo Driven Robot adopts European streamline design, whose transverse beam, guide beam and upper and lower arms are standard profiles, leading to compact structure and beautiful appearance.

· Safety

Position limit sensors and blocks effectively prevent mechanical and electrical malfunctions. Control board is designed to CE EMC test with short circuit and noise proof functions.

· Humanization

Servo driven axis provides the possibility of multi points for positioning products and sprues.

· Convenience

Control hardware fixtures are designed with flyer structure which provides benefit to maintenance. Cable drag chains help with cable management and ease for maintenance.

· Intelligence

Real time remote monitoring and telediagnosis assist better equipment management. USB port allows fast data updating, saving and loading.

3.Details:

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.