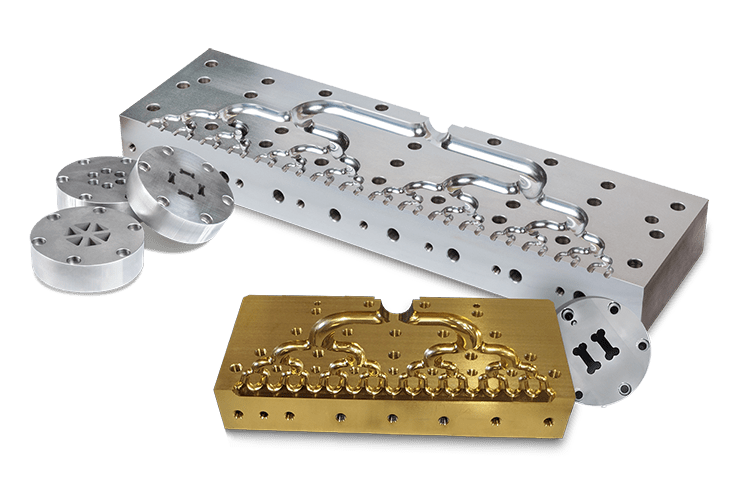

Industrial Extruction Mould

1.Product Introduction

At Kaihua Mold, we offer exceptional moulding solutions for Industrial Extrusion Dies. Our team of engineers is dedicated to ensuring that every extrusion die we create produces a quality final product, always maintaining the uniform exit velocity and output consistency.

Our engineers begin by testing the material to be extruded using computer flow analysis. This data ensures that we have the critical information needed to create and build a custom die, whether single-layer or multi-layer, that fulfills all material requirements.

At Kaihua Mold, we focus on the key factors that make an industrial extrusion die successful. This includes creating a design that guarantees uniform flow, temperature management, and precise dimensions. Our expertise in the field enables us to provide the required level of accuracy for achieving the desired outcomes.

We provide moulding solutions for various industries such as automotive parts manufacturing, construction, and packaging industries. Our team of experts has a wealth of experience in the extrusion industry and understands the importance of producing high-quality industrial extrusion dies.

At Kaihua Mold, we use the latest technology and equipment to manufacture custom extrusion dies for various applications. Our clients can expect reliable and efficient moulding solutions that guarantee quality results every time.

In conclusion, if you are in need of a reliable and experienced team to provide excellent industrial extrusion moulding solutions, look no further than Kaihua Mold. We offer high-quality services that guarantee consistent results and customer satisfaction. Contact us today to learn more about our services and how we can help with your next project.

2.Advantages

· High Quality

· Short Cycle

· Competitive Cost

3.Project Cases:

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.