Lowest Price for Injection Mold Maker - Car bumper mould – KAIHUA

Lowest Price for Injection Mold Maker - Car bumper mould – KAIHUA Detail:

The front and rear ends of the car are equipped with bumpers, which not only have decorative functions, but more importantly, they are safety devices that absorb and alleviate external impacts, protect the body and protect the body and the occupants.

The front and rear bumpers of the car are mainly made of metal materials. The U-shaped channel steel is stamped from steel plates with a thickness of more than 3 mm, and the surface is chrome-plated. It is riveted or welded with the frame rails, and there is a large gap with the body. It seems that an attached part looks very unattractive.

With the development of the automobile industry and the large-scale application of engineering plastics in the automobile industry, automobile bumpers, as an important safety device, have also moved on the road of innovation. At present, in addition to maintaining the original protection function of the front and rear bumpers of the automobile, it is also necessary to pursue harmony and unity with the shape of the car body, and to pursue its own lightweight. The front and rear bumpers of a car are made of plastic, and they are called plastic bumpers.

Automotive division annually make about 1200 moulds on average, especially good at large and medium-sized interior mold, classic case such as foaming dashboard mould for ford, Volkswagen, Benz, the Great Wall and stc., stack mould of door panel for audi, gas-assisted door panel mould, highlights non-mark grille mould, low-pressure molding column mould for jaguar

Sanmen base covers an area of 36,000 square meters with over 350 employees, and produces over 600 sets of molds annually. It is specialized in plastic injection moulds for automobile parts like automobile bumpers, fences, lamps and other exteriors system parts; automobile dashboard, door panel and other interior decoration system parts; wind frame, wind blade, flume and other cooling system parts. It mainly provide moulds and services to well-know automobile brands such as GM, FORD, VW, BMW, BENZ, Peugeot, RENAULT, Magna, FIAT, VOLVO, NISSAN, TOYOTA, and well-known automobile enterprises such as IAC, PO, Faurecia, Viston, BOSCH, BEHR, Valeo and Denso. 70% of the moulds are exported to more than 30 countries or regions such as Europe, North America, South America, Asia and etc.

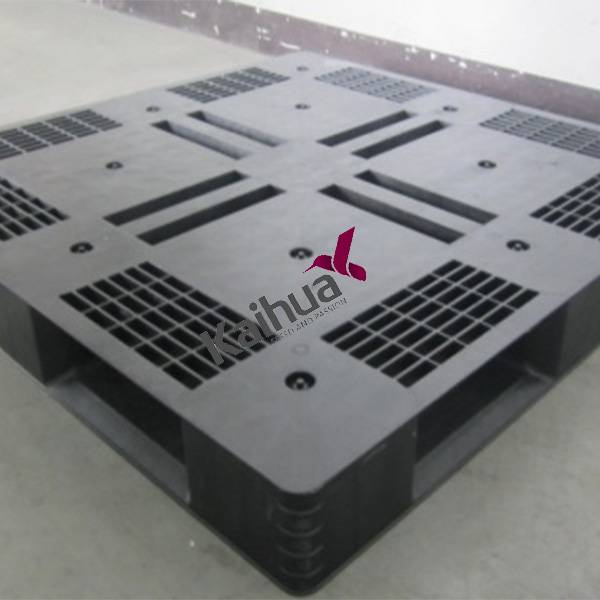

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Lowest Price for Injection Mold Maker - Car bumper mould – KAIHUA , The product will supply to all over the world, such as: Tanzania, Ethiopia, Riyadh, With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!