Manufacturer of Plastic Molded Parts - Logistics Division – KAIHUA

Manufacturer of Plastic Molded Parts - Logistics Division – KAIHUA Detail:

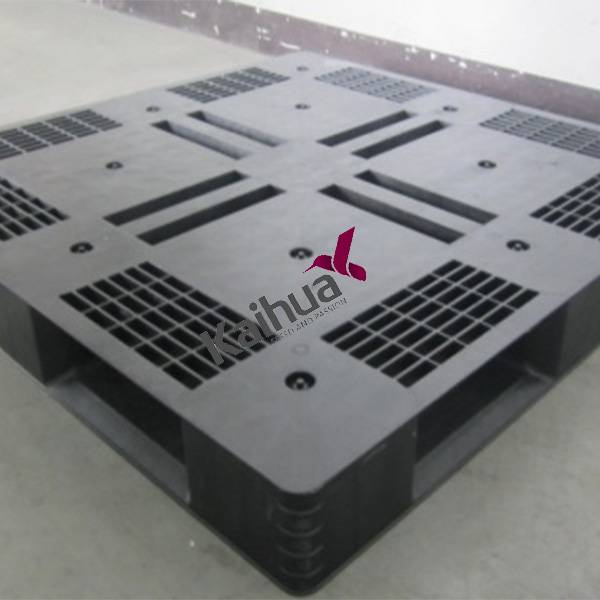

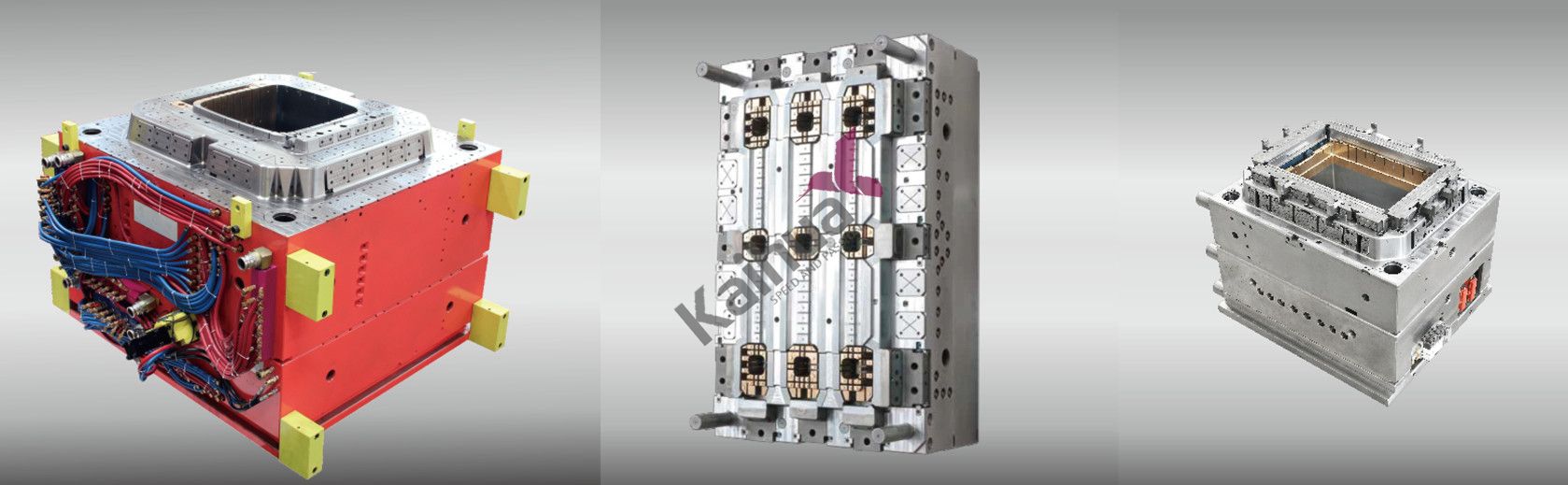

Solution and mould making for dustbin, pallet, crate etc. Most of the moulds are exported to clients in Europe and America market. Currently we can supply large mould weighting up to 90T.

We are capable to make dustbin moulds range from 40L to 3200L. With rich experience we have obtained year by year, our moulds can have very fast cycle time and long mould life. We can provide moulding solutions for industrial crates as well as big agricultural crates. By deep study on how to change versions easily, we help our client to save mould and production cost. No matter small, easy handle pallet or clean, stable pallet for food, hygiene segment. Our moulds are always built with short cycle time as well as easily changeability. Meanwhile, we can provide service for dynamic and static loading analysis.

our advantages

High Quality (Mold & Product Quality)

On-time delivery (Approval Sample & Mould Delivery)

Cost Control (Direct & Indirect Cost)

Best Service (Service to Customer, Employee & Supplier)

System— U8 ERP management system

Routine—Project Engineering Control

Document—ISO9001-2008

Standardization—Performance Assessment System

Good moulds lies first in good design.

By researching along with domestic and international excellent peers, our design team are not only good at 2D, 3D products and mould design but also bring great value such as “efficient” and “lightweight” as much as possible to our customers.

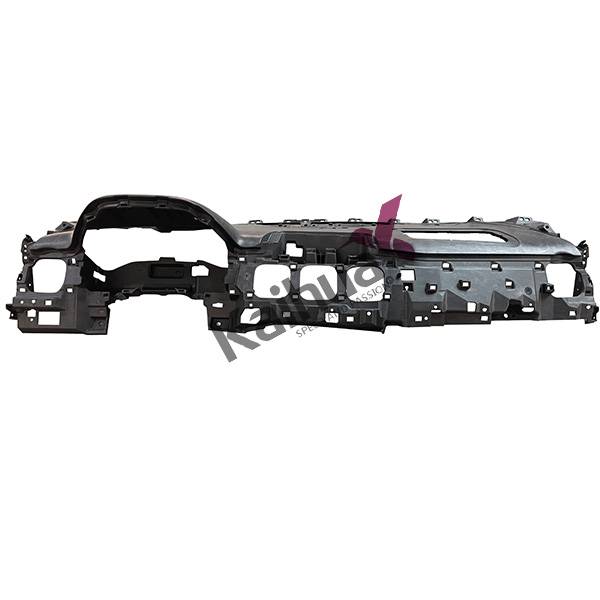

Product design team: we assist customers in B side design and feasibility analysis. With or without design, we can develop product design based on the requirements.

CAE team: making research together with our customers, such as loading analysis, strength analysis, gas or foaming simulation etc.

Mould design team: relying on rich experience and professional software, we can quickly respond to customer’s needs and create design which is easy to machine, easy to use, easy to do maintainance, and safe to make production.

■5 axis CNC groups: DMG from Germany, OKUMA and MAKINO from Japan, FIDIA from Italy. Max.stroke is 4000×2000×1100mm

■EDM groups: DAEHAN double-ended and four-ended EDM machining center from Korea. Max.stroke is 3000×2000×1500mm

■Milling center: Kuraki horizontal boring and milling machining center from Japan. Max.cutting depth is 1100mm.

■CMM groups: WENZEL from Germany, HEXAGON from Sweden and COORD from Italy. Max.measuring stroke is 2500×3300×1500mm.

■Others: SCHENCK balance test equipment from Germany, hardness test equipment from US, ow-rate inspection machine, water & hydraulic integrated inspection machine.

■Spotting groups: up to 500T

■Injection machines: Krauss maffei from Germany, HAITIAN, YIZUMI. Parallel movement, magnet clamping/hydraulic clamping, with 5-axis robot, barrel ret for Mucell, up to 3300T.

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for Manufacturer of Plastic Molded Parts - Logistics Division – KAIHUA , The product will supply to all over the world, such as: Denmark, Brazil, Ghana, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!