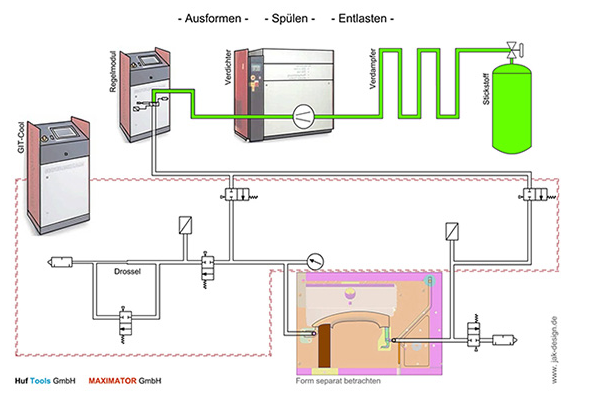

Gas assistance refers to the use of high-pressure inert gas (N2) injected into the molten plastic to form a vacuum section and push the molten material forward to realize the processes of injection, holding, and cooling.

Due to gas has efficient pressure transitivity, it keeps the pressure consistent throughout the airway, which can eliminate internal stress, prevent product deformation, and greatly reduce the pressure in the cavity, so it does not need a high clamping force during the molding process. Gas assistance is able to lighten the weight of the product, shrink sink marks, cut the loss and improve the service life of the mold.

The gas-assisted equipment includes a gas-assisted control unit and a nitrogen generator. It is another system independent of the injection molding machine, whose only interface with the machine is the injection signal connection line.

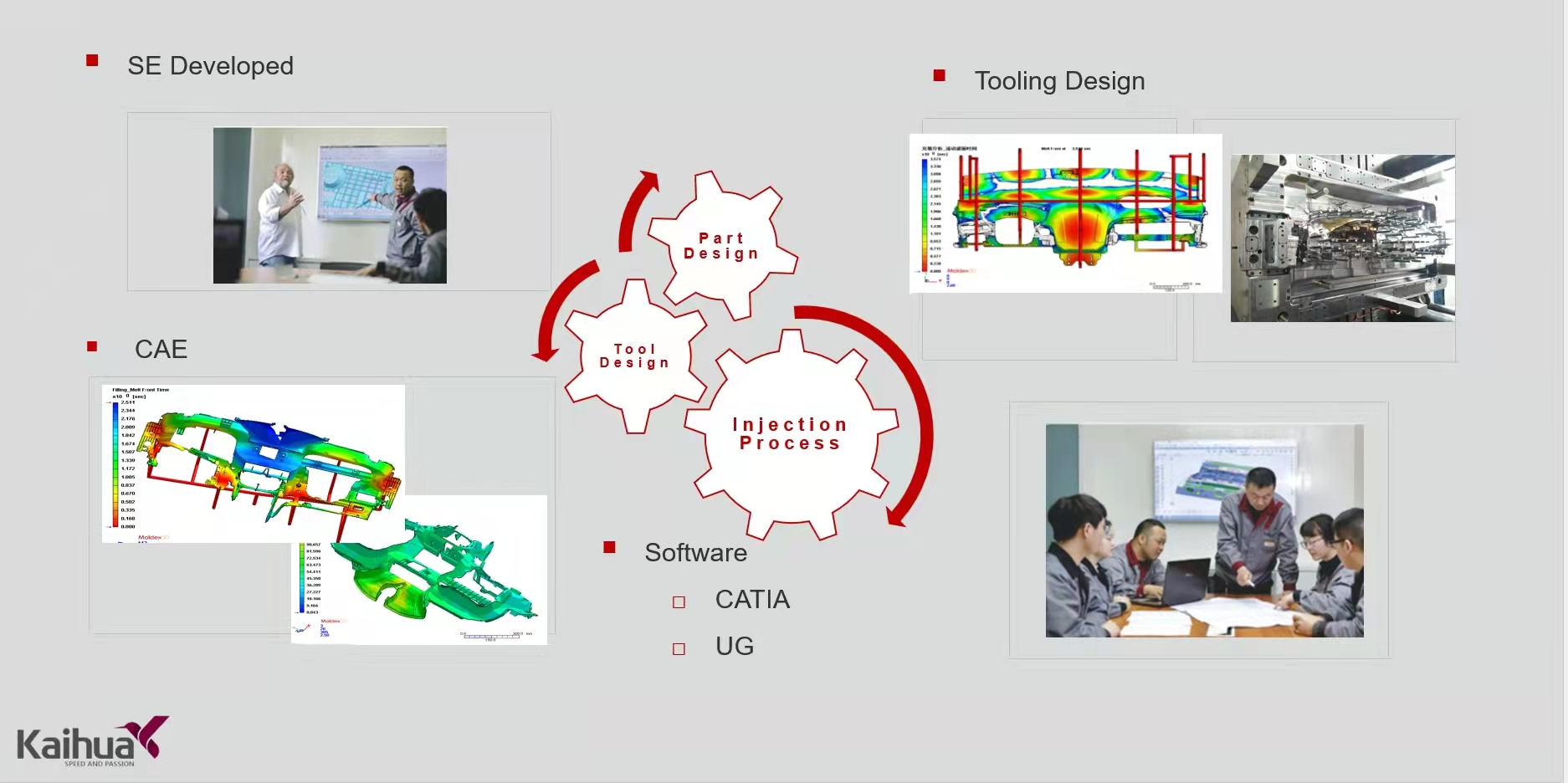

Kaihua Mould has widely applied gas-assisted technology in the fields of automobiles and household daily necessities. At present, it has reached good cooperation with Jaguar Land Rover, Audi and Volvo.

Post time: Jun-02-2022