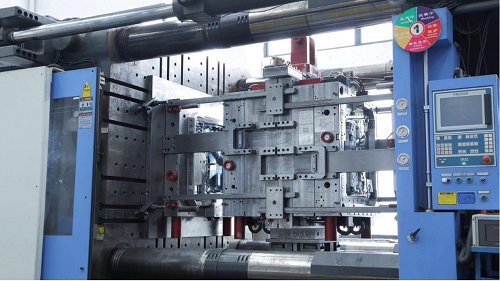

Different from conventional molds, the cavity of the stack mould is distributed on two or more layers, which is equivalent to stacking and combining multiple molds together. The most common two-layer die stack is usually installed by two single-layer dies back-to-back, and the parting surface is usually opened synchronously by the gear and rack mechanism.

Stack mould reduces injection molding production costs and tooling costs. The ordinary mold needs 2 injection molding machines, but the stack mold only needs 1 injection molding machine. Usually, when an injection molding machine is used in conjunction with a conventional mold, its injection volume and mold opening stroke only use 20%-40% of the rated value, which does not give full play to the performance of the injection molding machine. Compared with the conventional mold, the two-layer mold has nearly 100% improvement in production efficiency compared with the standard mold, and the clamping pressure is about 10% larger than that of the standard mold, which greatly improves equipment utilization and productivity.

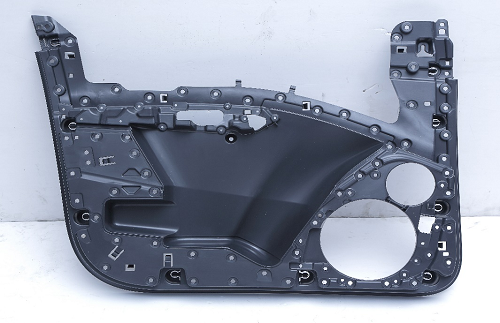

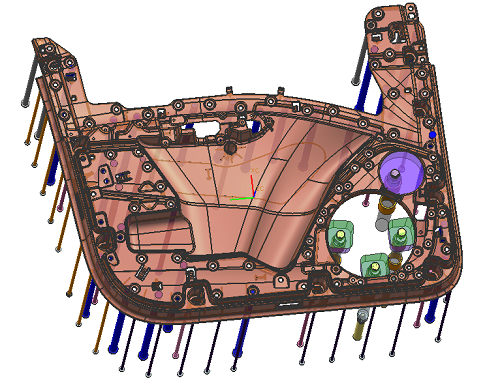

Kaihua Mould has applied the stack mould to automobile, household, daily necessities and other fields, and established in-depth cooperation with Audi and IKEA.

Post time: Jul-22-2022