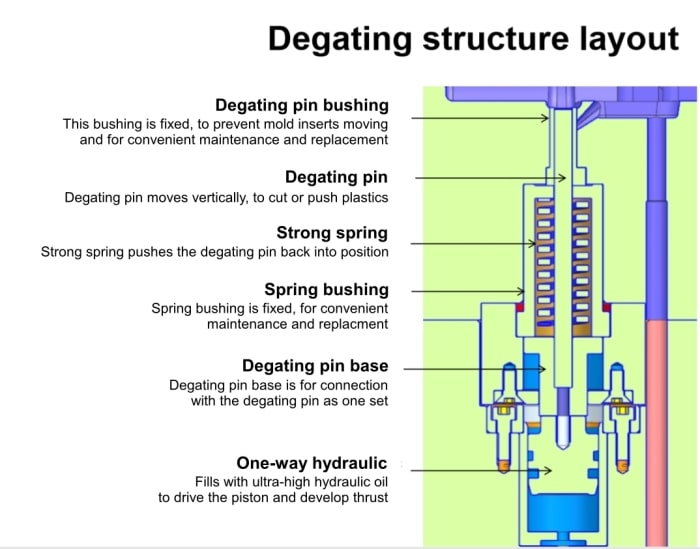

In-mold degate is an automatic separation technology of the material gate of the plastic part and the product. A typical in-mold degate system consists of the following parts: micro ultra-high pressure oil cylinder, high-speed and high-pressure cutter, ultra-high pressure sequence control system and auxiliary parts.

In-mold degate dies are widely used in developed countries and regions in the world today. This is mainly because the in-mold degate die has the following salient features:

①The gate separation in the mold is automated, reducing the dependence on people.

After the traditional plastic mold is opened, the product is connected to the gate, and two processes are required for manual shear separation. The in-mold hot-cutting mold advances the gate separation before the mold is opened, eliminating the subsequent process, which is conducive to production automation and reduces the dependance on people.

② Reduce the artificial quality impact of products.

In the process of in-mold hot-cut mold forming, the automation of gate separation ensures the consistency of appearance at the separation of the gate, and the result is a part with consistent quality, while the traditional manual separation of the gate process cannot guarantee the appearance of the separation of the gate. Therefore, many high-quality products on the market are produced by in-mold hot-cut molds.

③ Reduce molding cycle and improve production stability

The automation of in-mold thermal cutting avoids useless human actions in the production process, and the fully automated mechanical shearing of the product ensures quality consistency, which has incomparable advantages over traditional molds in the mass production process of products.

Post time: Sep-23-2022