The 19th China Tray International Conference and 2024 Global Tray Entrepreneurs Annual Meeting will be held in Ningbo from November 27-29, 2024. The conference aims to explore the application of intelligent and green technologies in the tray industry and tray recycling, and share advanced technology application cases. ZheJiang Kaihua Logistics Technology Co., Ltd was invited to participate and independently developed, designed, and manufactured the first domestic mucell tray mold with ZheJiang Kaihua Logistics Technology Co., Ltd, injecting new vitality into the tray industry and setting a new model for green development.

During the conference, Daniel Liang, Chairman of Kaihua, delivered a wonderful speech on the theme of “Kaihua Mold Continuous Innovation Helps the High Quality Development of the Plastic Industry”. In his speech, he elaborated on Kaihua’s deep cultivation and meticulous work in technological innovation, demonstrating how it innovates tray products with advanced technology in the tray manufacturing and logistics industry; And the exquisite research and ingenuity in management innovation, allowing the audience to deeply appreciate Kaihua’s pioneering attitude and strong strength in the industry.

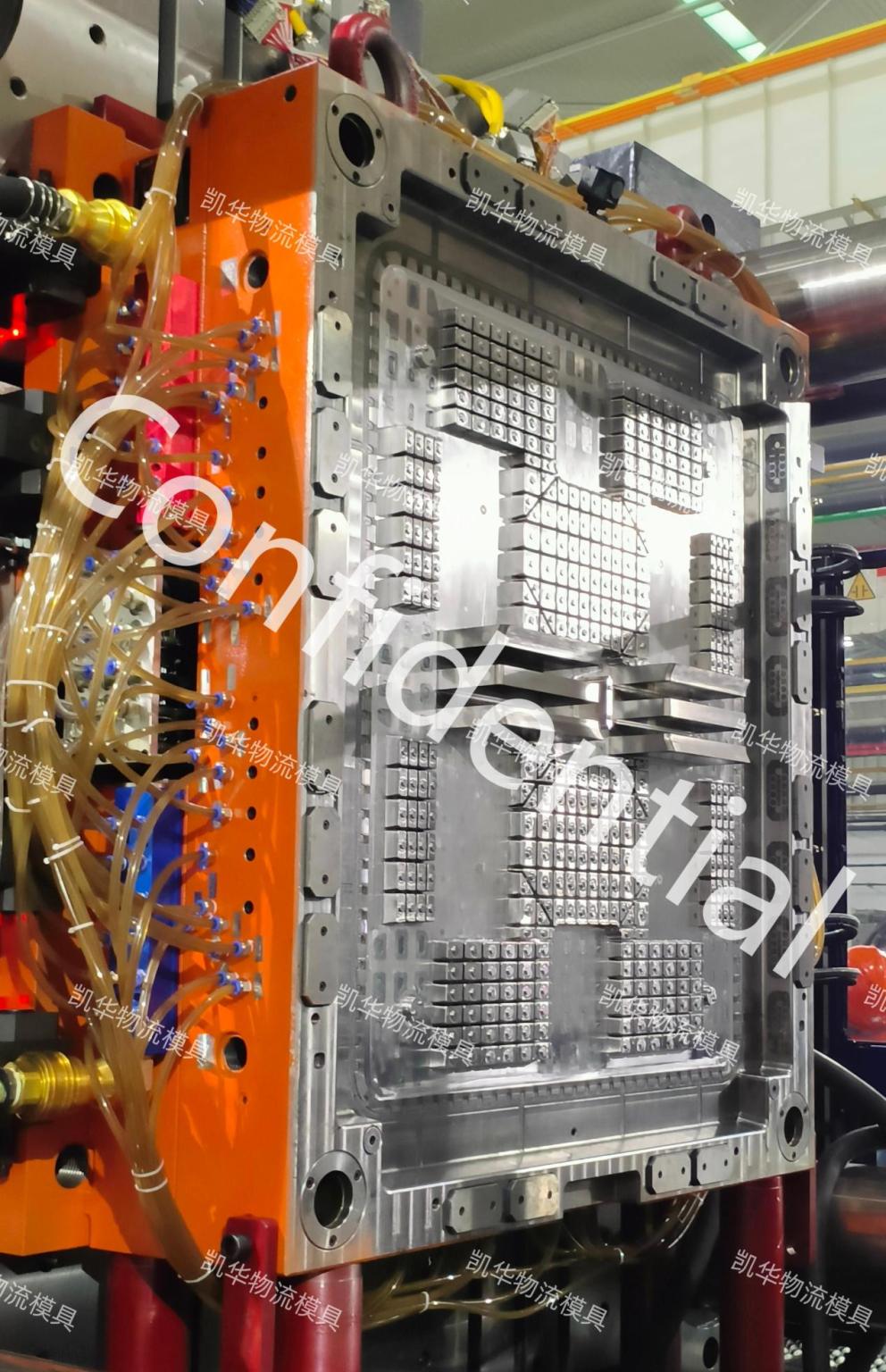

On the afternoon of November 28th, at the 12th factory of Haitian, the injection molding production of the first domestic KHL-Y1210WT-1 mucell tray mold designed, developed and manufactured by ZheJiang Kaihua Logistics Technology Co., Ltd was showcased. This tray adopts mucell technology, which can fully optimize the performance of materials through micro foaming technology. Its grid shaped tray design, combined with the four-way fork handling method, makes the tray more stable and efficient during handling and storage.

This mucell field tray has a size of 1200x1000x140mm, a production cycle of 165 seconds, and is made of PP material. After physical foaming treatment, the weight of the tray has been reduced from 17.4kg to 15.2kg. This plan not only reduces weight by 10-15%, saves materials and costs, and lightens production, but also significantly reduces production costs. The locking force is reduced by 27%, reducing load and cost, saving 5% in production cycle, and improving machine capacity. In addition, the seamless design improves overall strength, ensures dimensional stability, eliminates deformation, and is easy to handle.

The debut of Kaihua mucell tray mold will undoubtedly trigger a wave of green and lightweight transformation in the tray industry. This tray product adopts green and environmentally friendly technology, and the raw materials can be recycled and reused. This feature makes it stand out in today’s increasingly stringent environmental requirements, and points out the direction for the sustainable development of the tray industry.

Post time: Dec-27-2024