One of Hottest for China Custom Auto Front Bumper Plastic Injection Mould Moulding Part for Car

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of One of Hottest for China Custom Auto Front Bumper Plastic Injection Mould Moulding Part for Car, Our organization has been devoting that “customer first” and committed to helping buyers expand their company, so that they become the Big Boss !

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of China Plastic Mould, Custom Plastic Injection, With the first-class goods, excellent service, fast delivery and the best price, we’ve got won highly praise foreign customers’. Our merchandise have been exported to Africa, the Middle East, Southeast Asia and other regions.

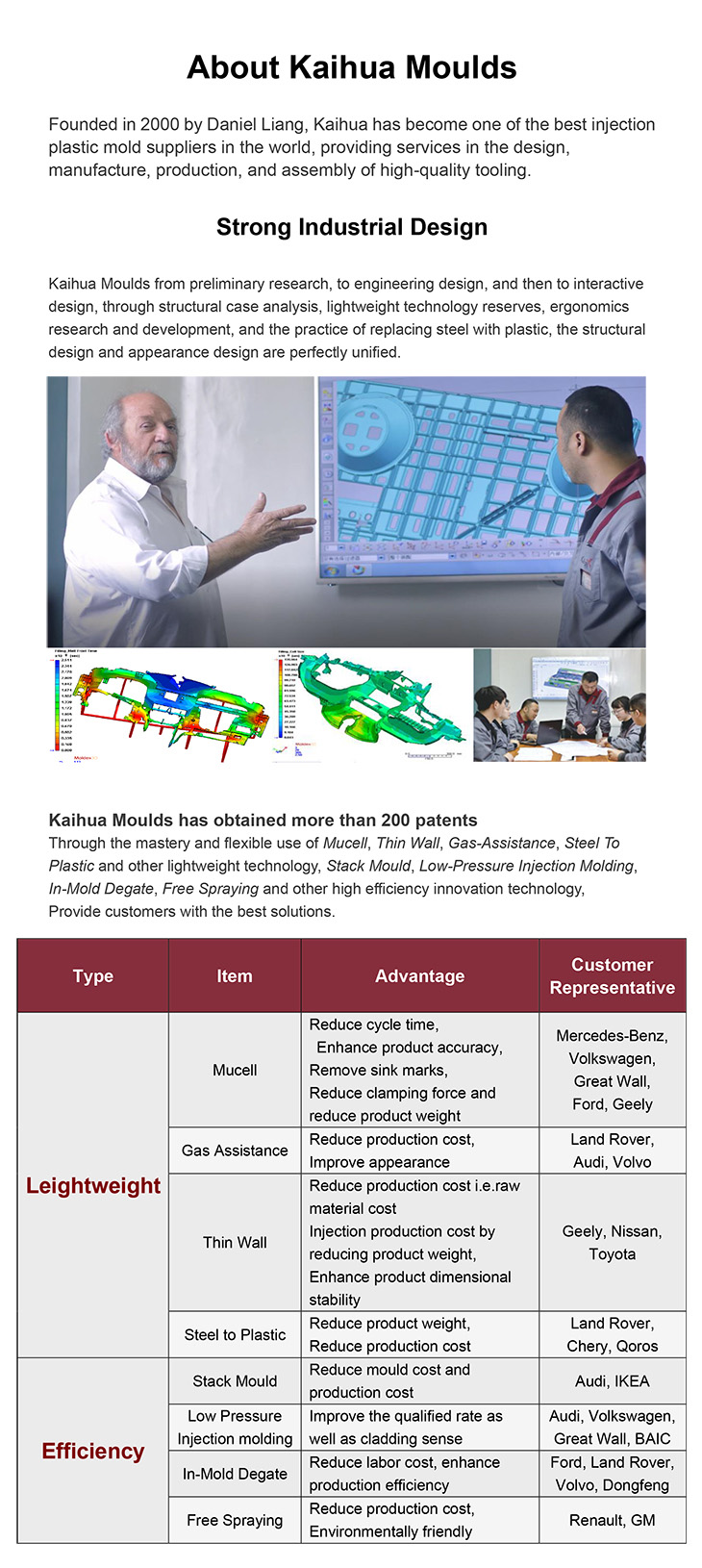

1.Product Introduction

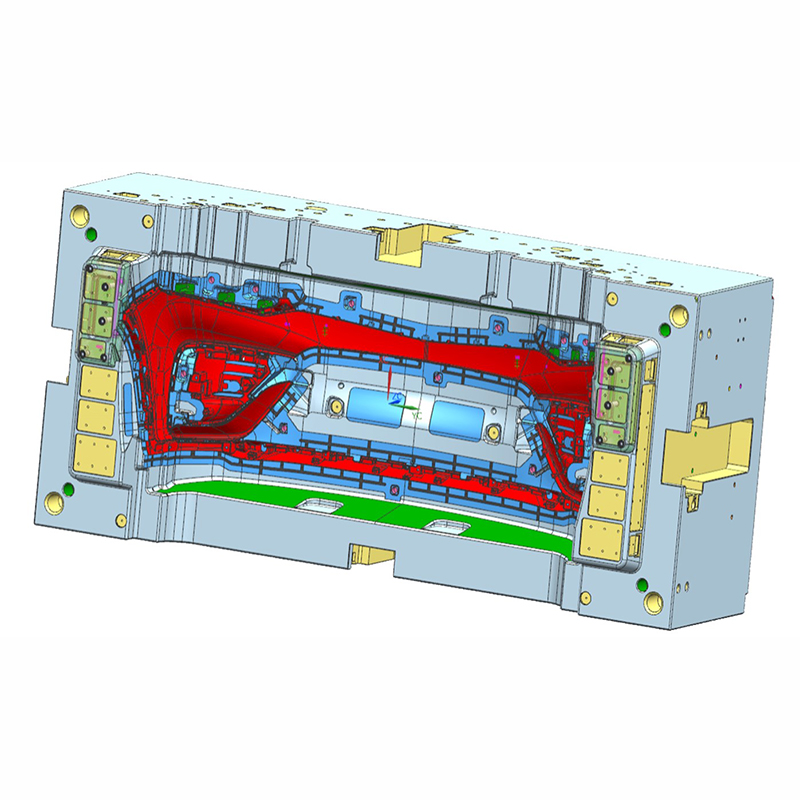

We can provide customers with the best solutions for Automotive Plastic Injection Molding for Internal Parting Car Bumper.

Kaihua Service include: Product Design, Mold Design, Mold Making, Products Research & Development & Produce, Provide Processing Injection Molding For Tier 1.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | P20, 718, 8407, Nak80, H13, S136, DIN 1.2738, DINt |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc, or your requirement |

| Shaping Mode: | Plastic Injection Mould |

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Quote | According to Samples, Drawing and Specific Require |

| Production Capacity | 2400 Sets/Year |

| Design Software | CATIA, UG |

3.Product Feature and Application

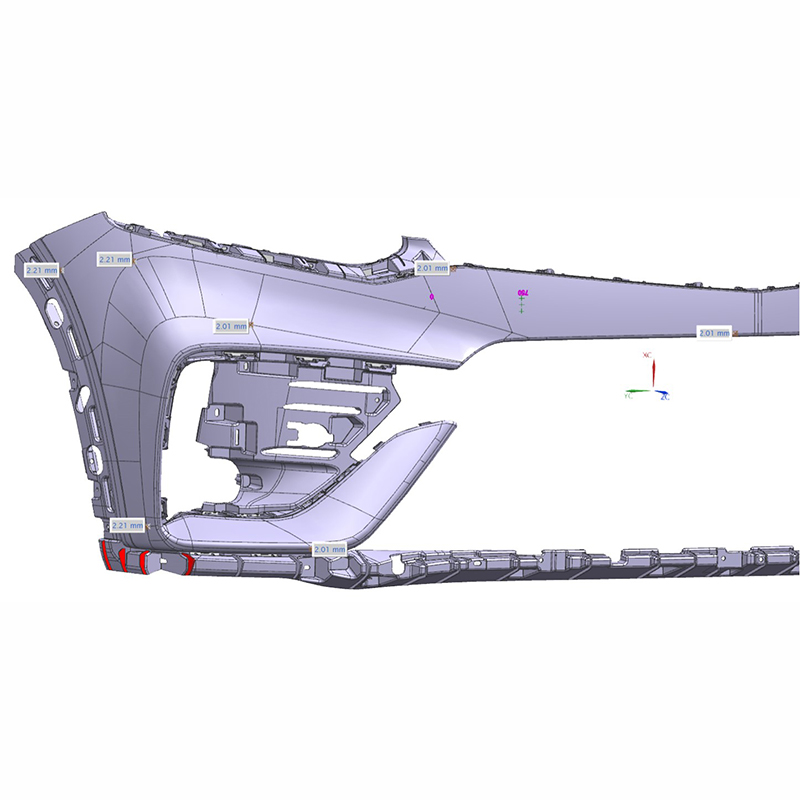

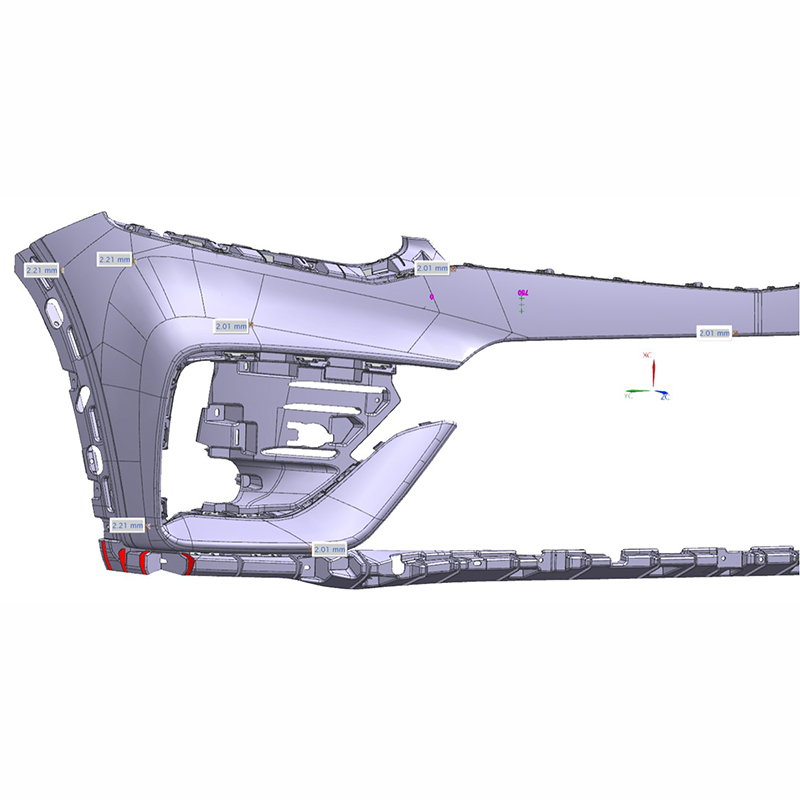

Technical Features : Internal Parting Car Bumper

2.Unequal thin-wall design

The middle area is 2.0mm, and the ends on both sides are thickened gradually to 2.2mm.

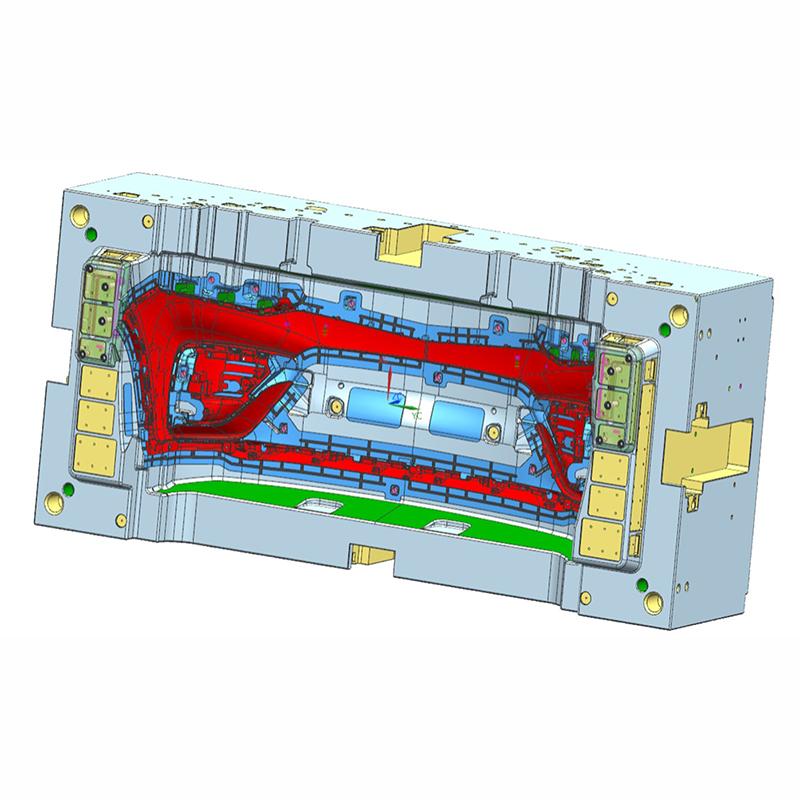

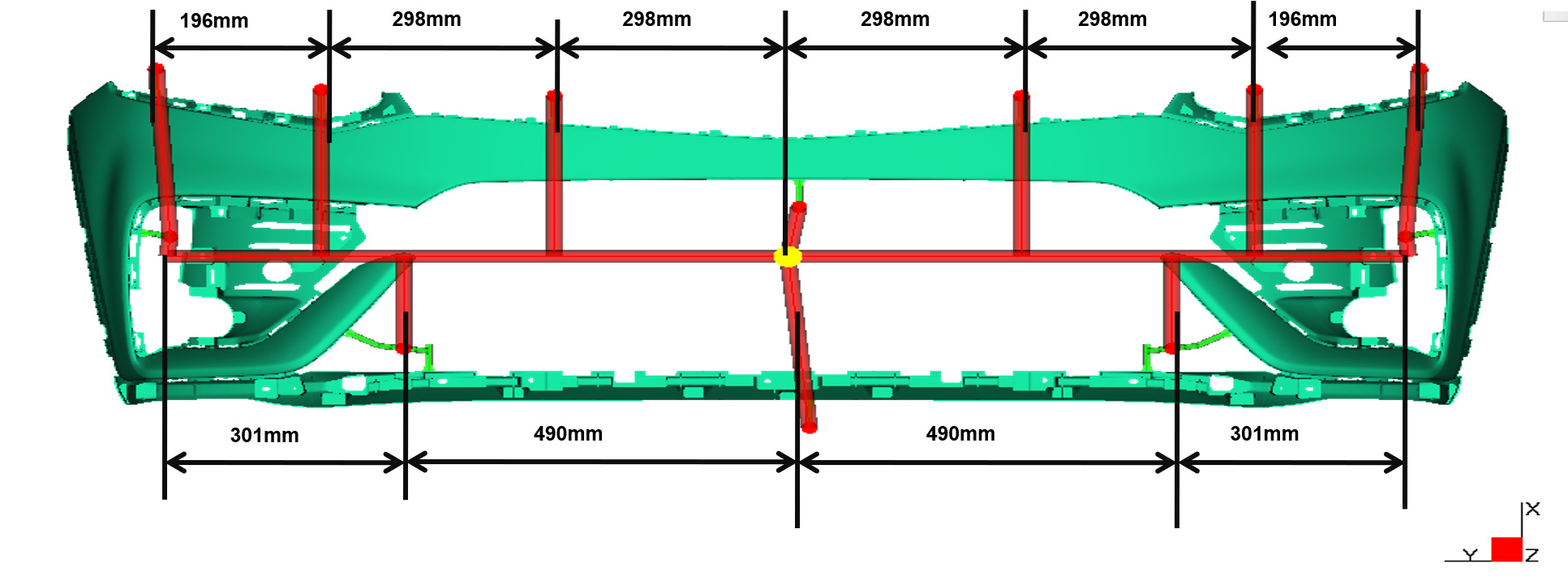

2.Hot runner scheme

2.Hot runner scheme

The hot runner scheme using Synventive Sequence valve gate 12 drops.

3.Simulated fill time (About 7.1s)

3.Simulated fill time (About 7.1s)

4.Cavity parting technology

4.Cavity parting technology

The internal parting bumper is perfectly injection-molded at one time through the secondary track change track control technology, therefor ensuring the appearance quality of the bumper and saving the processing procedures and processing costs of plastic parts.

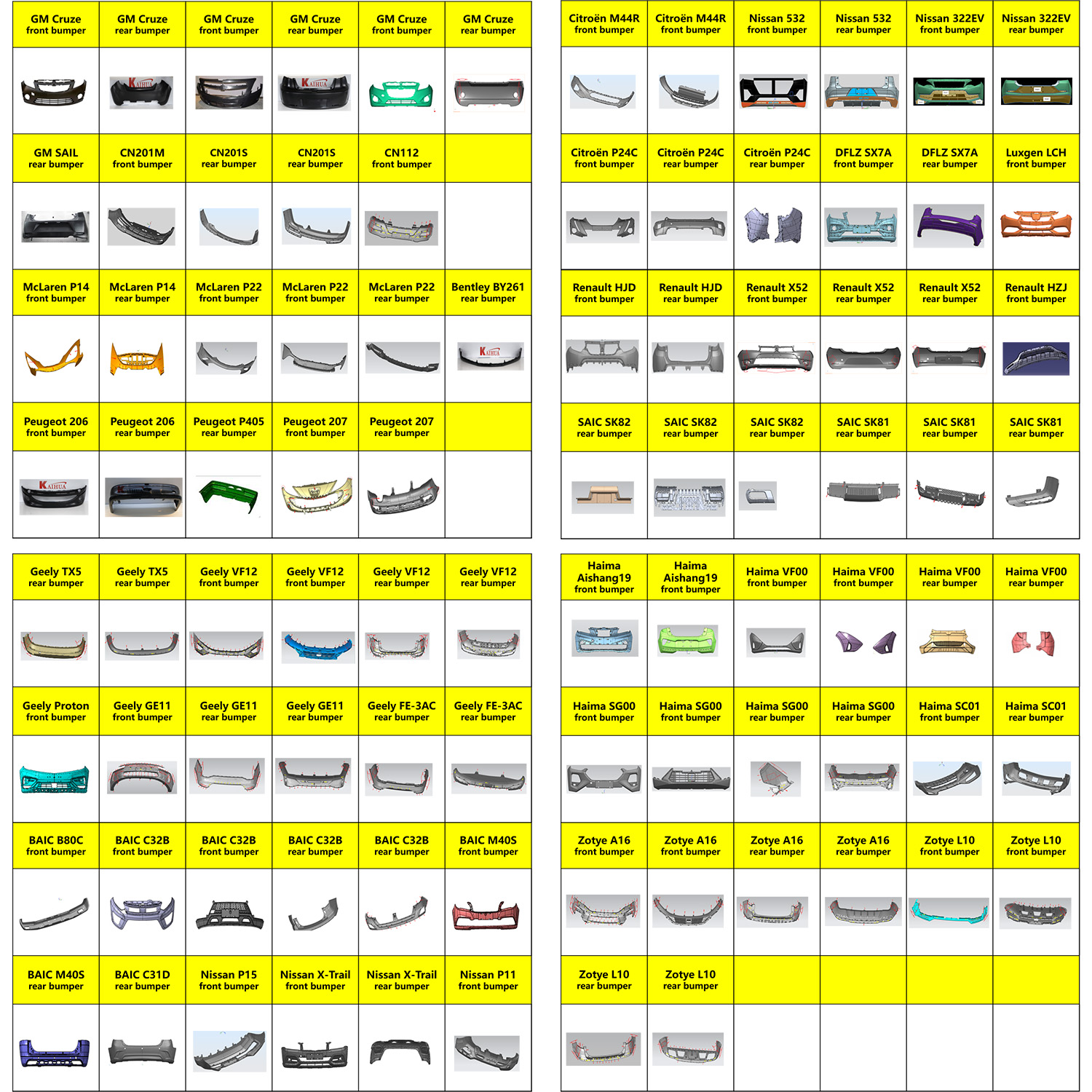

4. Cooperation Cases

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of One of Hottest for China Custom Auto Front Bumper Plastic Injection Mould Moulding Part for Car, Our organization has been devoting that “customer first” and committed to helping buyers expand their company, so that they become the Big Boss !

One of Hottest for China Plastic Mould, Custom Plastic Injection, With the first-class goods, excellent service, fast delivery and the best price, we’ve got won highly praise foreign customers’. Our merchandise have been exported to Africa, the Middle East, Southeast Asia and other regions.