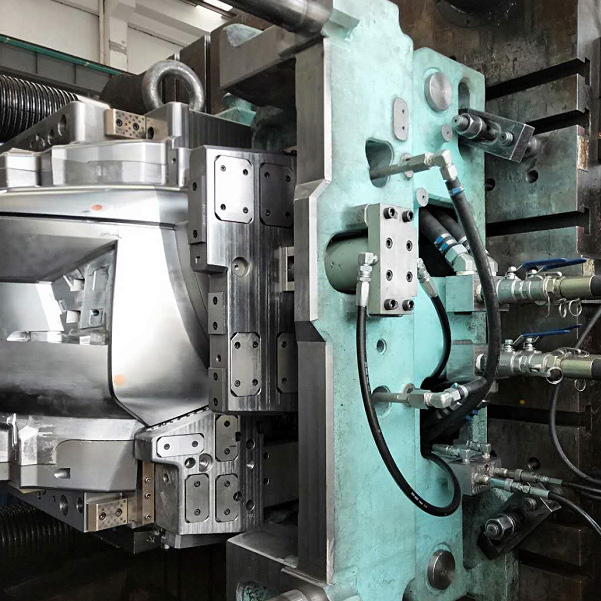

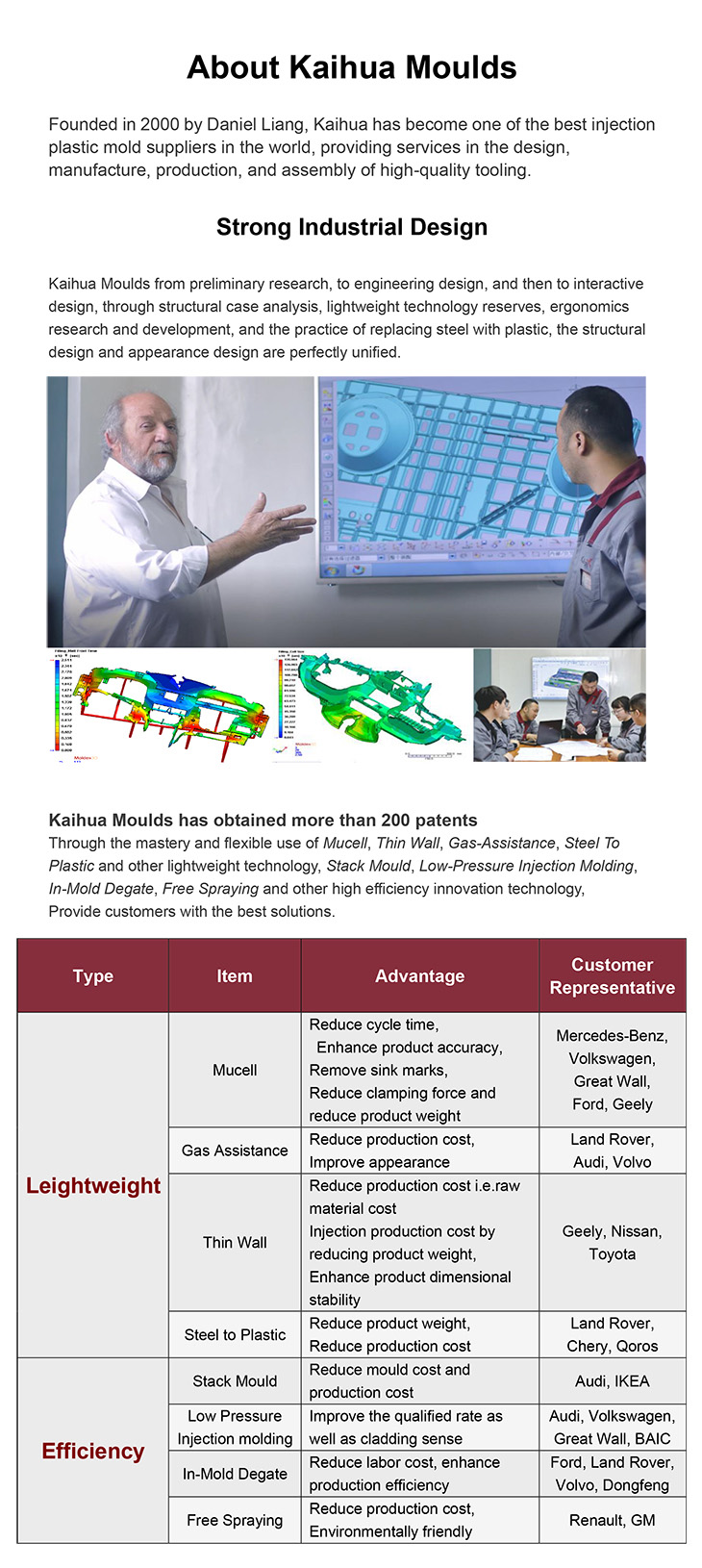

Reliable Supplier Plastic Injection for Car Bumper Mold

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for Reliable Supplier Plastic Injection for Car Bumper Mold, our products and solutions have excellent standing from the whole world as its most competive selling price and our most advantage of after-sale provider towards the clients。

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for China Auto Part Mould and Auto Part Mold, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We are going to continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

1.Product Introduction

We can provide customers with the best solutions for Automotive Plastic Injection Molding for Short Cycle External parting Car Bumper Mould.

Kaihua Service include: Product Design, Mold Design, Mold Making, Products Research & Development & Produce, Provide Processing Injection Molding For Tier 1.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | P20, 718, 8407, Nak80, H13, S136, DIN 1.2738, DINt |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc, or your requirement |

| Shaping Mode: | Plastic Injection Mould |

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Quote | According to Samples, Drawing and Specific Require |

| Production Capacity | 2400 Sets/Year |

| Design Software | CATIA, UG |

3.Product Feature and Application

Technical Features 3: Short Cycle Mold

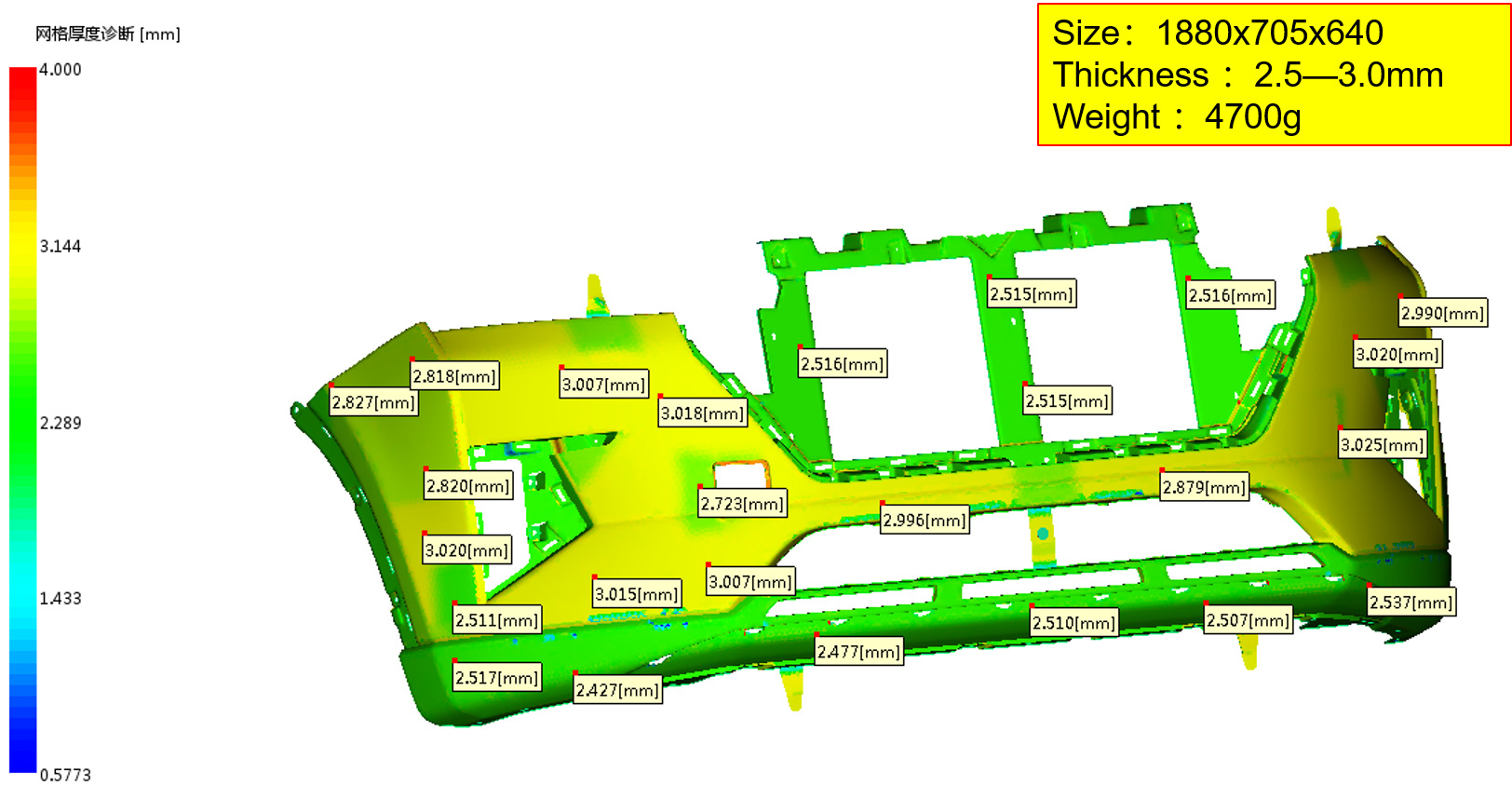

1.Thickness

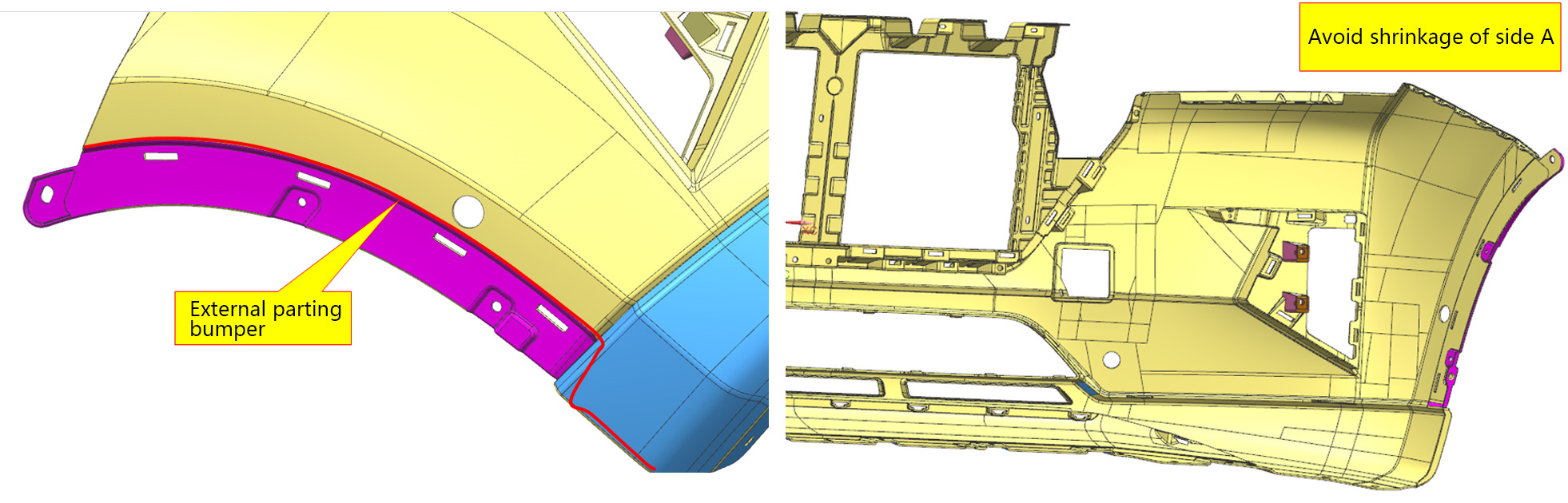

2.Product structure

2.Product structure

3.Simulated fill time (About 5.5s)

3.Simulated fill time (About 5.5s)

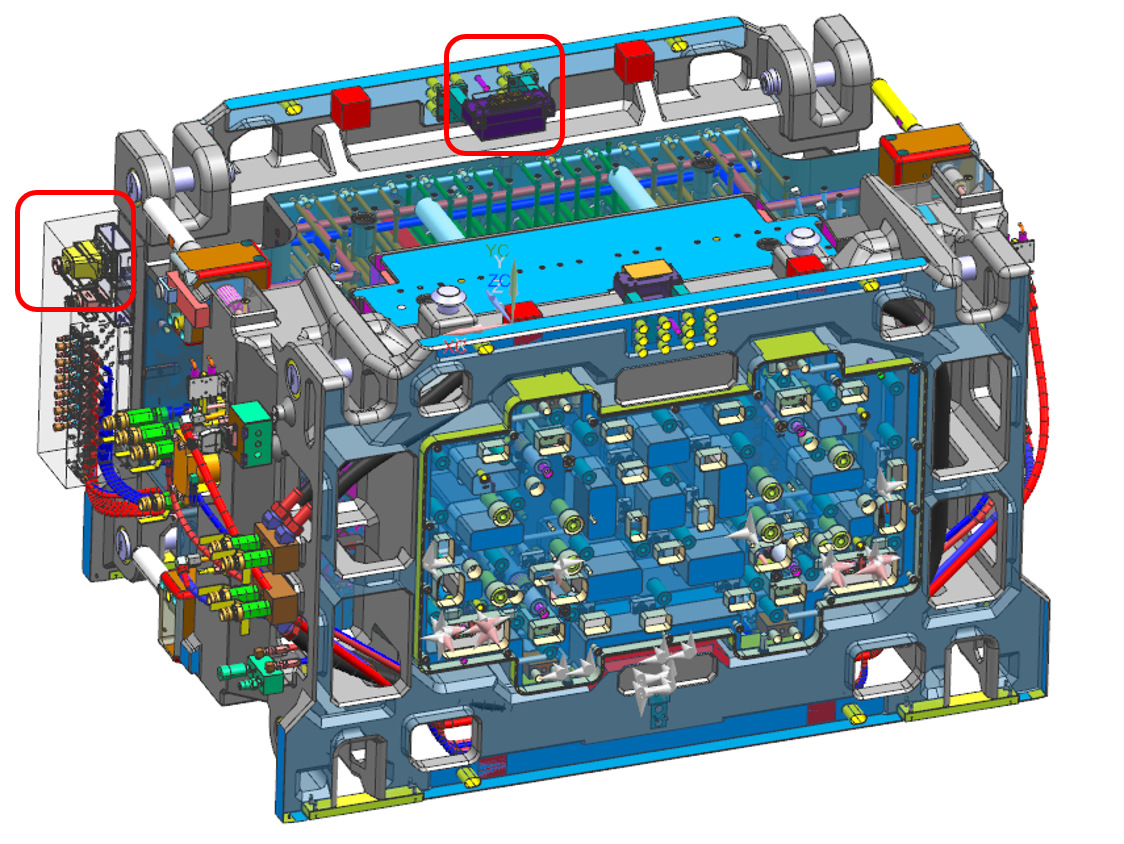

4.Hot runner scheme

4.Hot runner scheme

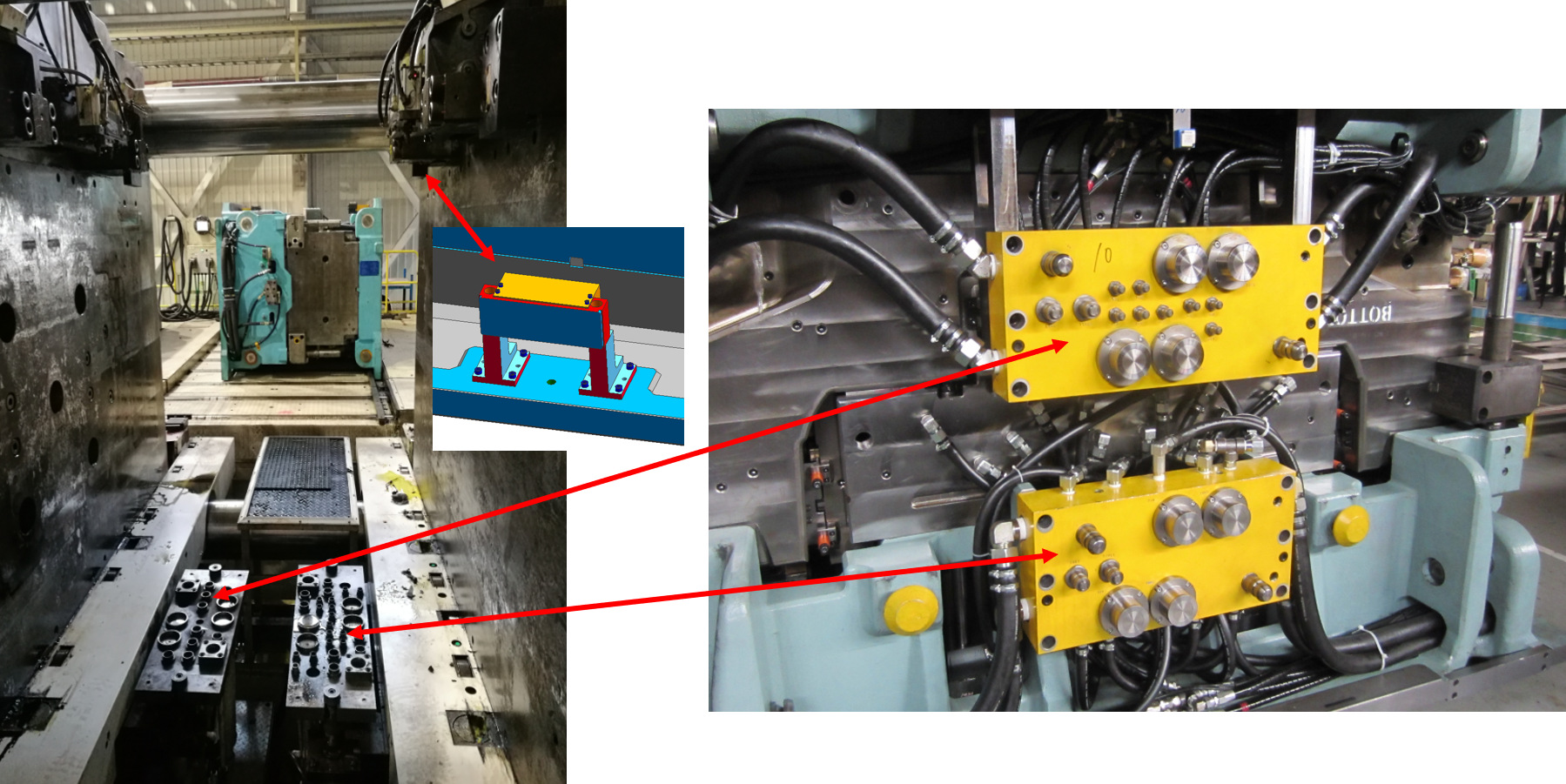

During factory production, the machine is automatically connected to the hot runner plug.

Preheat the plug in advance at the time of mold factory test, mold matching and factory production.

5.Automatic connection system

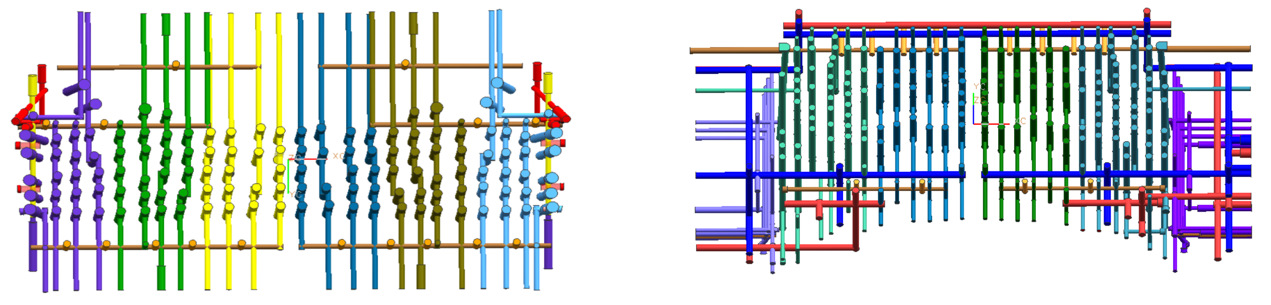

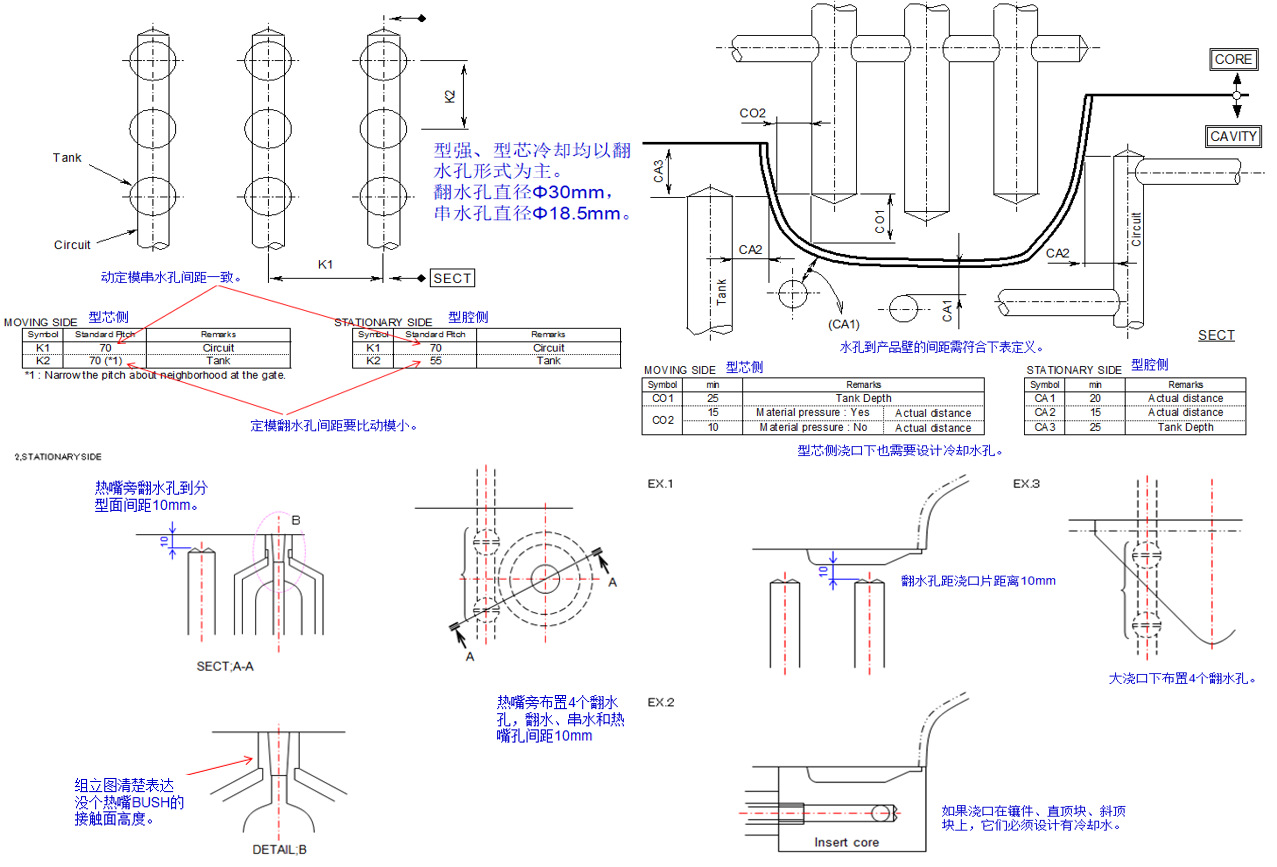

6.Cooling channels

6.Cooling channels

Mold Cooling Channels (Water channels) is one of the important systems in plastic mold.

Below are the channels of Core and Cavity respectively.

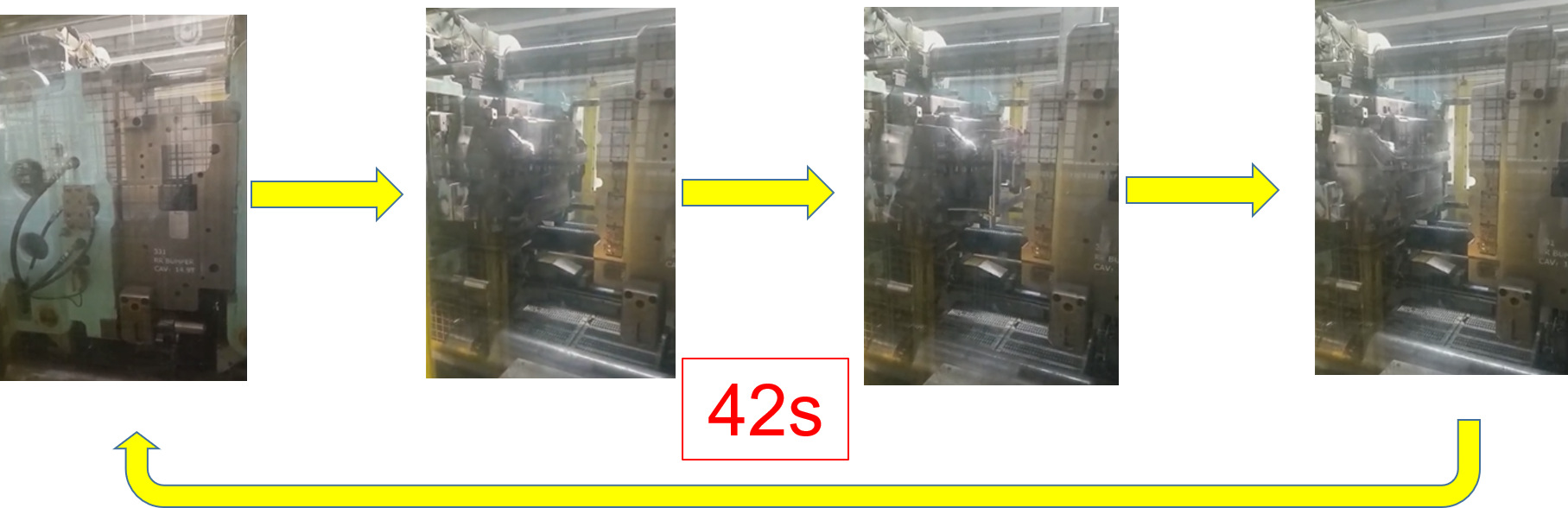

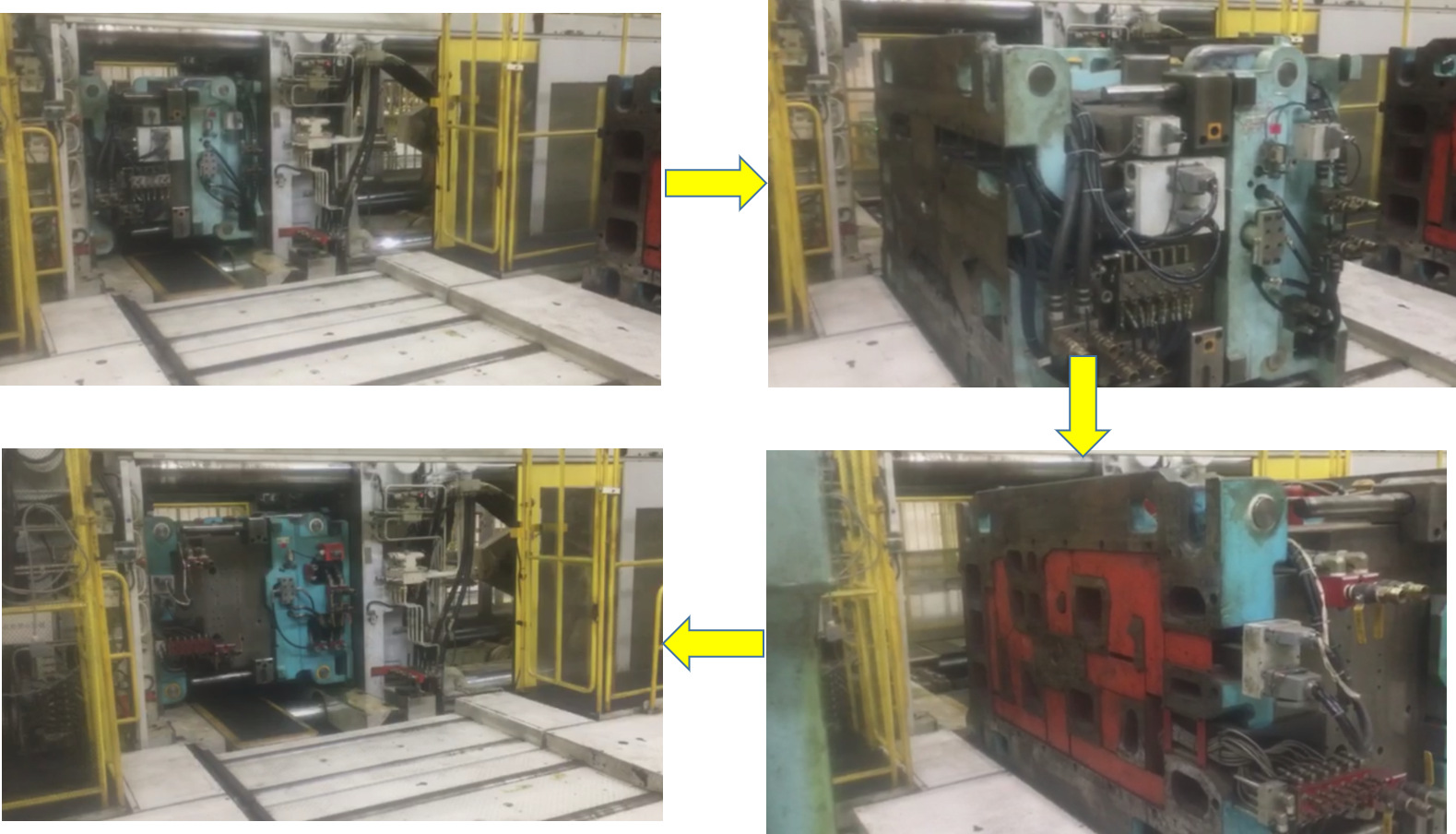

7.Automatic mold replacement

7.Automatic mold replacement

As shown in the following flow chart, the original mold of the injection molding machine is automatically replaced with other molds on the right.

8.Molding cycle

8.Molding cycle

Mold closing, injection molding, cooling, mold opening, ejection, part taking, resetting, mold closing. The total time for a complete production cycle is 42 seconds.

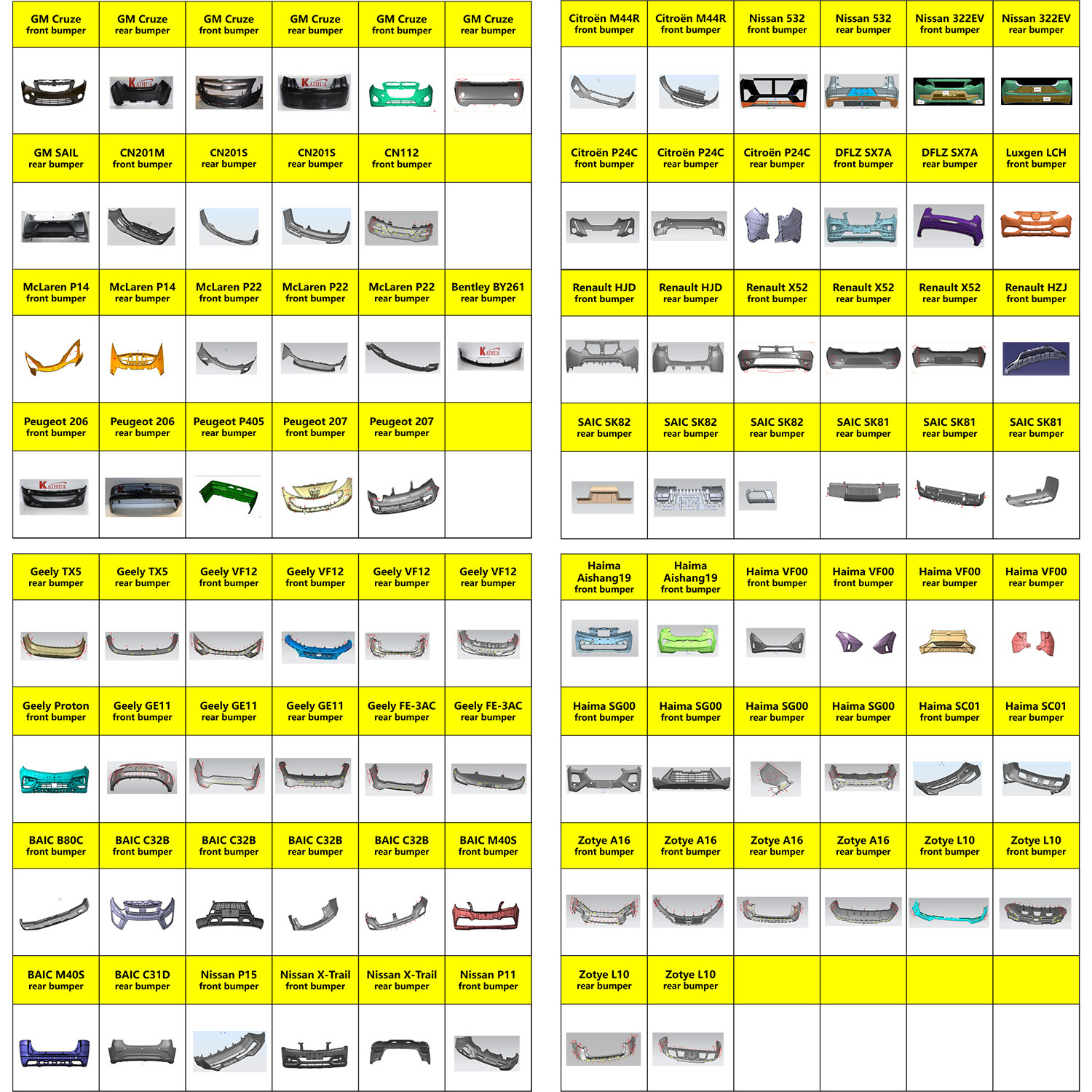

10.Cooperation Cases

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for Reliable Supplier Plastic Injection for Car Bumper Mold, our products and solutions have excellent standing from the whole world as its most competive selling price and our most advantage of after-sale provider towards the clients。

Reliable Supplier China Auto Part Mould and Auto Part Mold, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We are going to continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!