Steel NAK80

Product Introduction

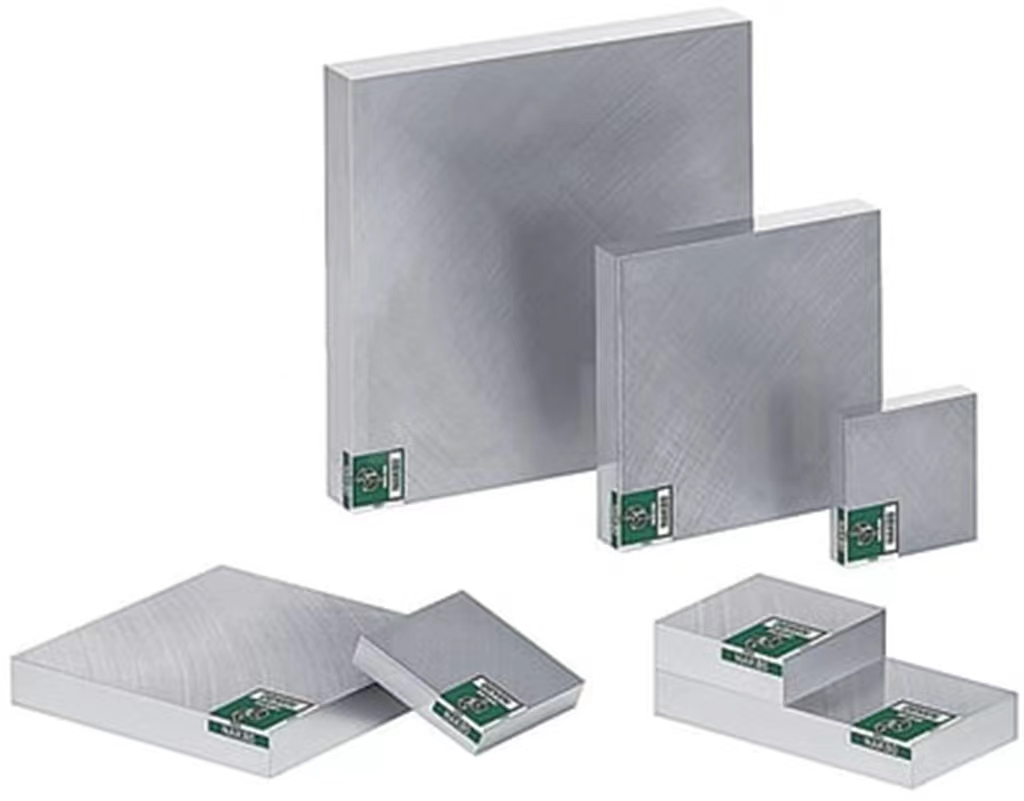

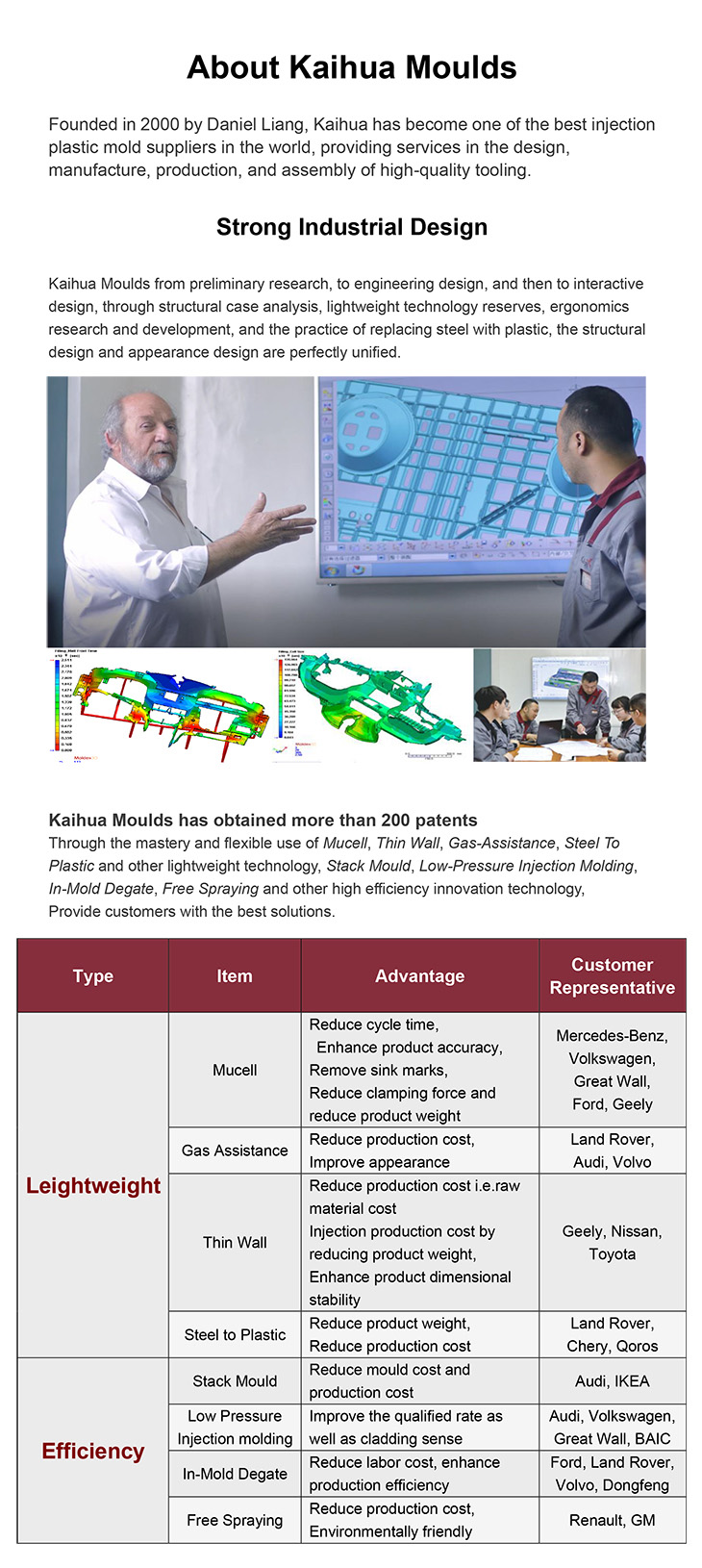

In the field of mold-making, Steel NAK80 has emerged as a popular choice for its exceptional properties that make it suitable for creating high-precision, mirror polishing molds. Steel NAK80 is a pre-hardened steel that has excellent polishability and toughness, making it ideal for manufacturing products that require a degree of finish, such as families, cars, cameras, computers, and other supplies on the transparent product molds.

One of the most significant advantages of Steel NAK80 is its high thermal stability. This property ensures that the mold remains stable under high temperatures, which is essential in molding processes that involve heating or cooling cycles. Moreover, Steel NAK80 also possesses excellent corrosion resistance and wear resistance properties, making it an ideal choice for manufacturing office automation equipment, automobile parts discharge processing molds, and other parts that require high precision and durability.

Kaihua Mold, a leading manufacturer and supplier of premium-quality mold-making materials, offers Steel NAK80 with exceptional surface finish and dimensional stability. The company's Steel NAK80 is manufactured using advanced technology and undergoes rigorous testing procedures to ensure it conforms to industry standards.

Kaihua Mold's Steel NAK80 is a versatile material that can be used in various molding processes, including injection molding, blow molding, and compression molding. It is also compatible with a wide range of resins, including ABS, PC, PMMA, and POM.

In conclusion, Steel NAK80 is an excellent material for manufacturing molds that require high precision and surface finish. Its exceptional properties make it ideal for use in various industries, including the automotive, electronics, and medical sectors. Kaihua Mold's Steel NAK80 is a reliable and high-quality material that is perfect for any molding project that requires precision and durability.

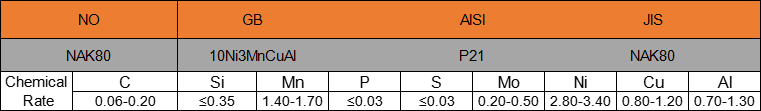

Classification