Up to 1100L-10L Waste Bin Injection Mould

1.Product Introduction

Up to 1100L-10L Waste Bin Injection Mould by Kaihua Mold

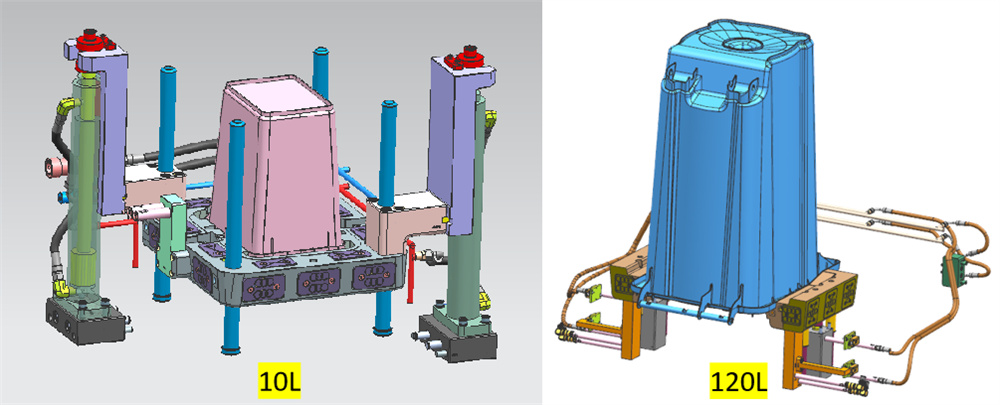

Kaihua Mold is a leading manufacturer of waste bin injection moulds. Our moulding solutions cater to bins ranging from 10L-42L up to 1100L. With our deep study on how to change versions easily, we help our clients save both mould and production costs. Our moulds are suitable for various types of bins including Rubbish Bins, Wheelie Bins, Trash Cans, and Litter Bins on the street.

Our dedicated team of professionals makes sure that all our moulds are built with fast cycle times and have a long mould life. Our commitment to excellence and quality has led us to become the preferred supplier of waste bin injection moulds to various industries.

At Kaihua Mold, we have the expertise, experience, and dedication to provide high-quality solutions to our clients. We understand that each project is unique and requires a customized approach. Therefore, we work closely with our clients to deliver solutions that meet their specific requirements.

Kaihua Mold is dedicated to customer satisfaction and delivering top-quality moulds that meet industry standards. Our state-of-the-art facilities and advanced technology ensure that all our products conform to the highest international standards.

In conclusion, our Up to 1100L-10L Waste Bin Injection Moulds are designed with precision and expertise to meet the diverse requirements of our clients. We are committed to delivering high-quality solutions that help our clients save both time and cost. Contact us today to learn how we can assist you with your waste bin injection moulding requirements.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | 45#, P20, H13, 718, 1.2344, 1.2738 or your requirement |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc10L-42L, up to 1100L. or your requirement |

3.Product Feature and Application

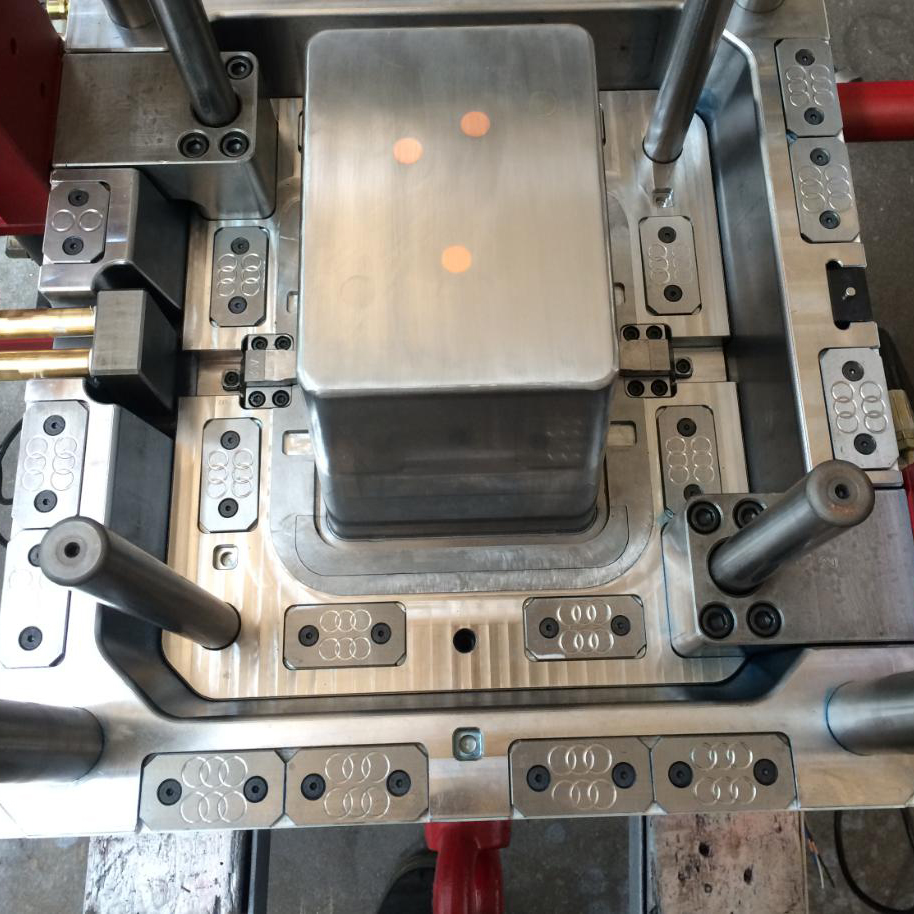

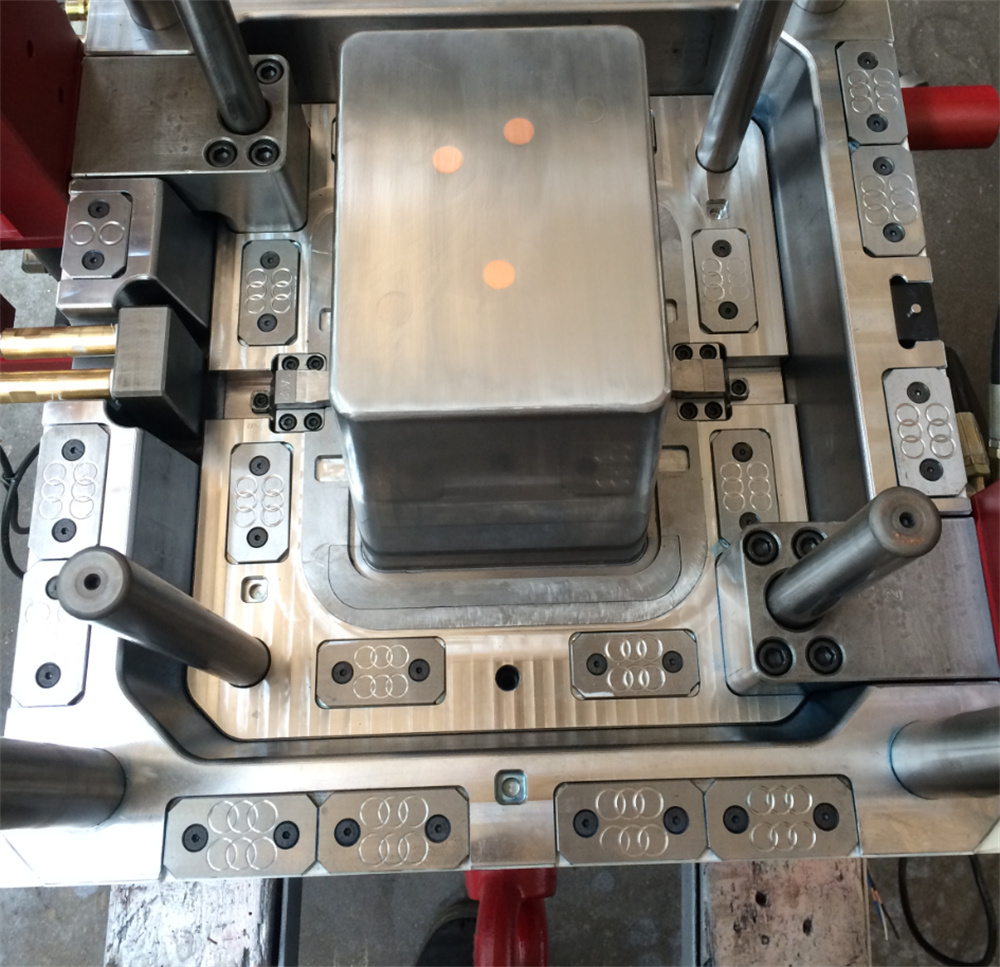

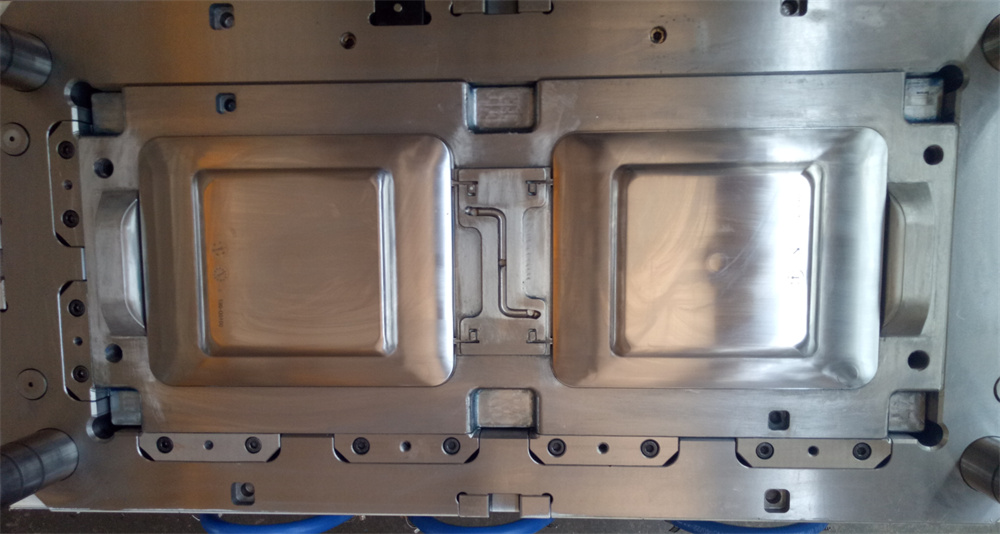

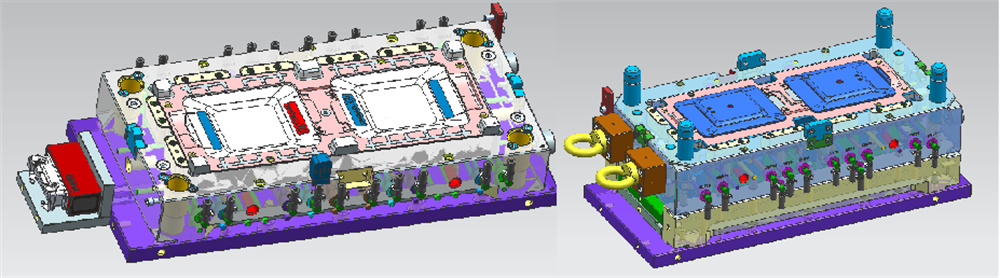

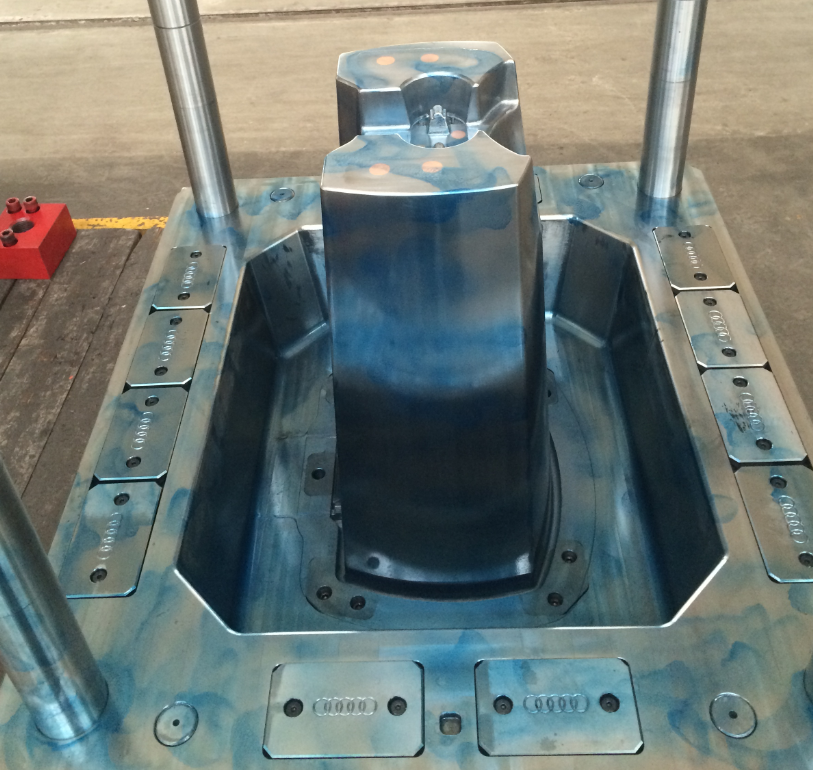

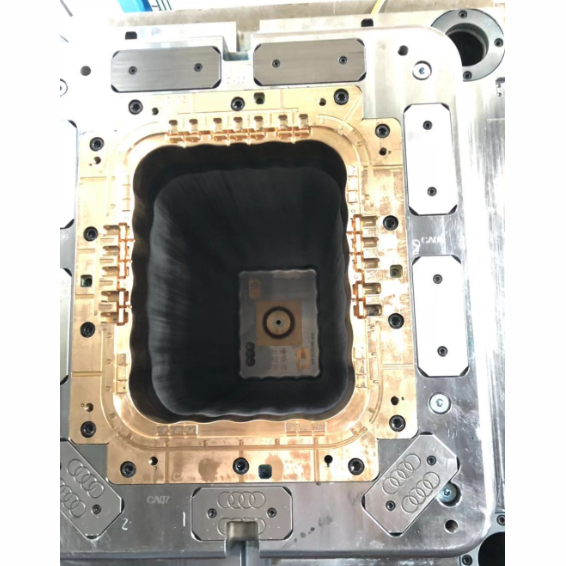

4.Production Details

We are able to check Injection mold design and run professional simulations to make sure that the product design can match with different standard.

For example, EN 840 norms for mobile waste containers.

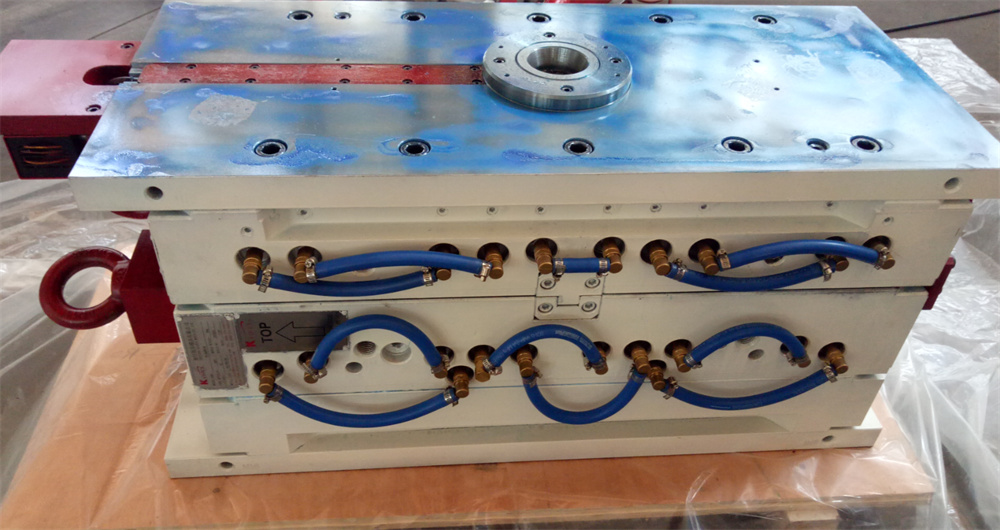

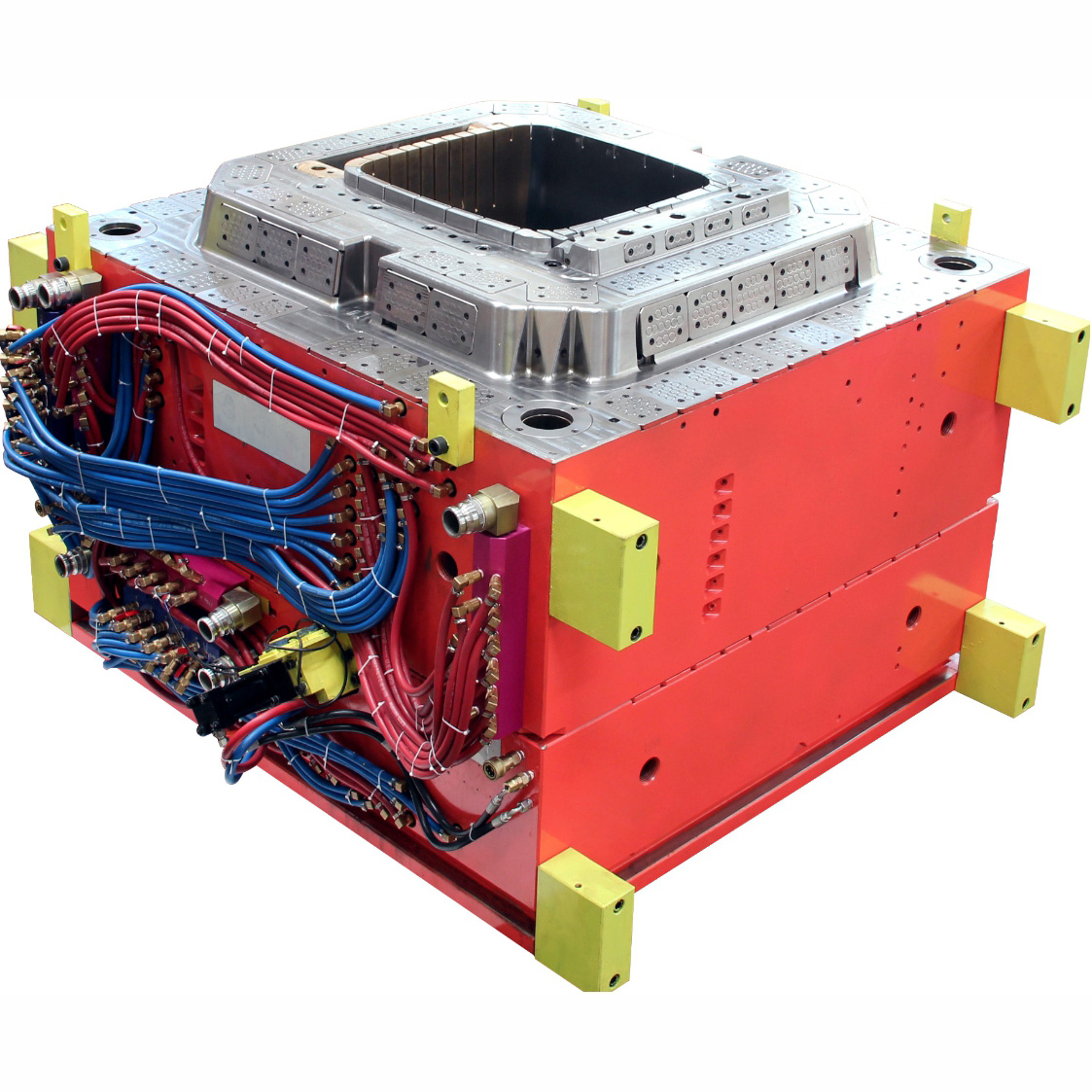

Cooling

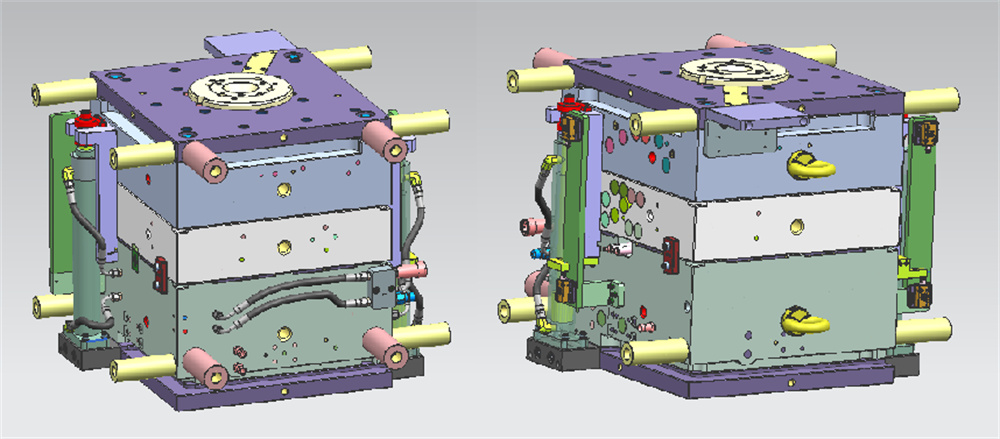

Example: 240L waste bin

Cycle time: ≦60s including robot pickup

There are 7pcs independent cooling manifolds with large size inlet/outlet connectors, which we can use them to control the temperature of each zones.

cavity side: A, B, C and Dcore side: E, F and G

Multiple cooling manifolds with

valve will ensure water flow controls.

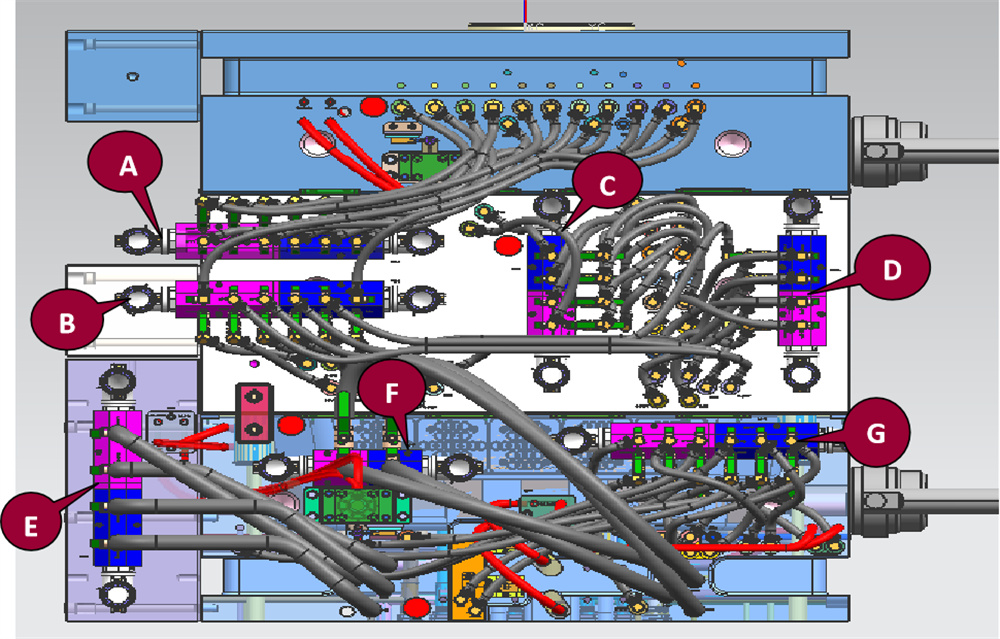

We will design good and reliable ejection system.

Sometimes it will be ejector blocks, or it can be stripper plate too.

Sometimes we use only air valves and robot to take out parts.

The ejection must be as simple as possible and design for easy maintenance.

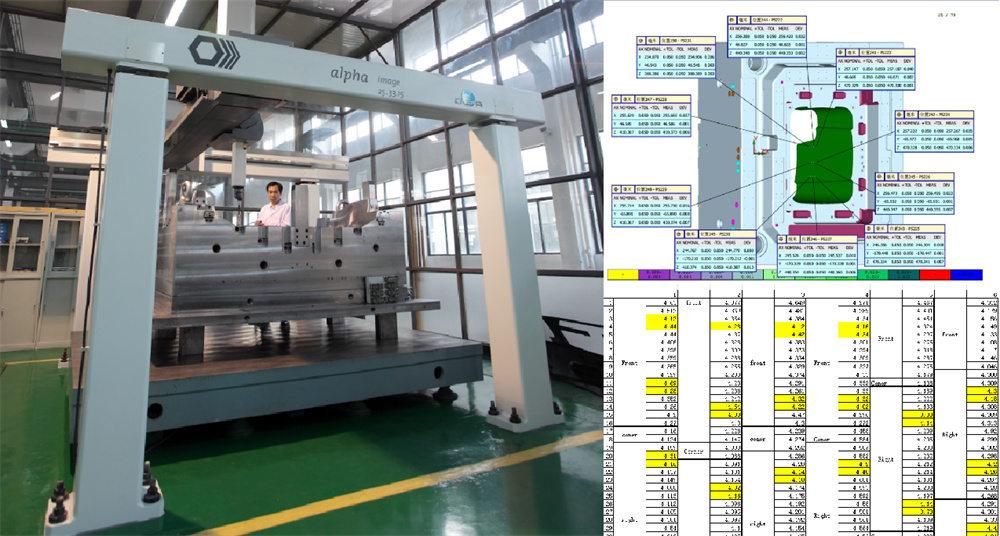

Machinery

Small to large size CNC including 5 axis high speed CNC

MAKINO Automation lines

Spotting machine 100-500T,

capable for all kind of injection moulds

CMM – dimensions/thickness

Krauss Maffei machines, all with robots,

from 160-1600T(multi-injection)

3200T injection machine, parallel movements, hydraulic clamping,

with 6-axix ABB robot.

It is not the biggest machine that we have.

We are now buying up to 5500T injection machine.

Product Introduction

This Five Axes Servo Driven Robot is divided into single cut and double cut for customers to choose, and it highly matches to two-plate mold, third-plate or hot runner mold. The robot can realize all kinds of special actions, such as arrangement, stacking, quality inspection and embedding, etc.

Product Parameter (Specification)

| Power Source | AC220V±10V 50/60 HZ |

| Drive System | Customized |

| Swivel | 90°Fixed Pneumatic |

| Standard | EUROMAP12, SPI, EUROMAP67 |

| Core Component | Motor |

| Video outgoing-inspection | Provided |

Details

Advantages

√ Aesthetic

This Five Axes Servo Driven Robot adopts European streamline design, whose transverse beam, guide beam and upper and lowaer arms are standard profiles, leading to compact structure and beautiful appearance.

√Safety

Position limit sensors and blocks effectively prevent mechanical and electrical malfunctions. Control board is designed to CE EMC test with short circuit and noise proof functions.

√Humanization

Servo driven axis provides the possibility of multi points for positioning products and sprues.

√Convenience

Control hardware fixtures are designed with flyer structure which provides benefit to maintenance. Cable drag chains help with cable management and ease for maintenance.

√Intelligence

Real time remote monitoring and telediagnosis assist better equipment management. USB port allows fast data updating, saving and loading.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management