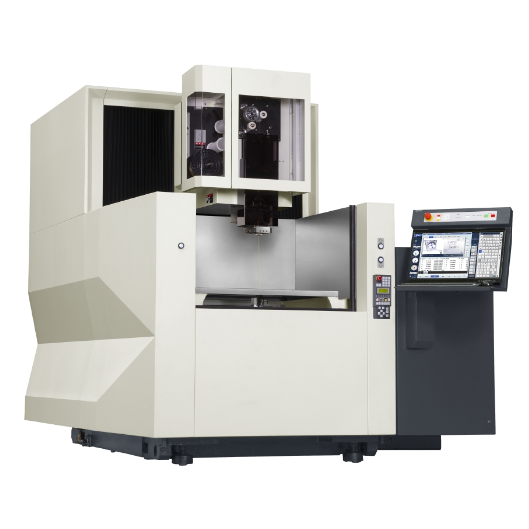

Vertical Injection Molding Machine

1.Product Introduction

As a leading provider of injection molding solutions, we are proud to offer our Vertical Injection Molding Machines. Each of our machines is designed and manufactured with the highest level of precision and quality, ensuring that our customers receive only the best equipment available on the market.

Our Vertical Injection Molding Machines are equipped with high rigidity clamping equipment and high-performance screw cylinders, ensuring that your production process operates smoothly and without interruption. Our electronic control technology is also state-of-the-art, providing reliable and accurate control over the entire injection molding process.

We understand that our customers require machinery that can be relied upon day after day, and that's why we have spared no expense in the development and production of our machines. With our Vertical Injection Molding Machines, you can be confident that you are investing in equipment that will meet your needs both now and in the future.

Furthermore, our machines have been optimized for easy operation, meaning that even those who are new to the process can quickly learn to use them. Additionally, with our customer support team always available to assist you, you can rest assured that you will have the help you need to get the most out of your investment.

At Kaihua Mold, we take pride in delivering high-quality injection molding solutions to our customers around the world. With our Vertical Injection Molding Machines, we are confident that we are providing a product that will meet all of your production requirements and exceed your expectations. Contact us today to learn more about our products and how we can help you achieve your goals.

2.Product Parameter (Specification)

| Theoretical Injection Volume | 471cm |

| Screw Diameter | 50mm |

| Max Shot Weight | 420g/14.8oz |

| Injection Pressure | 1856kg/cm |

| Injection Rate | 157cm3/s |

| Temperature Control Zone Num. | 4 |

| Hopper Capacity | 30L |

3.Advantages

· Light curtain and control system with touchscreen

· Screw cold start protection

· Emergency alarm and safety switch

· PID proportional temperature control

· Automatic fault display and shutdown and automatic cleaning device

· High-speed but low-pressure clamping device

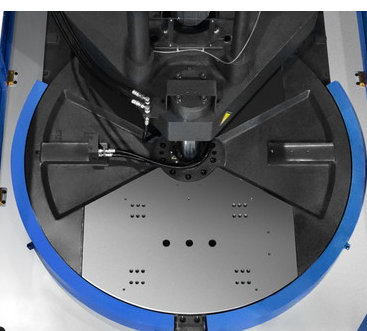

4.Details:

4.Advantages

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management