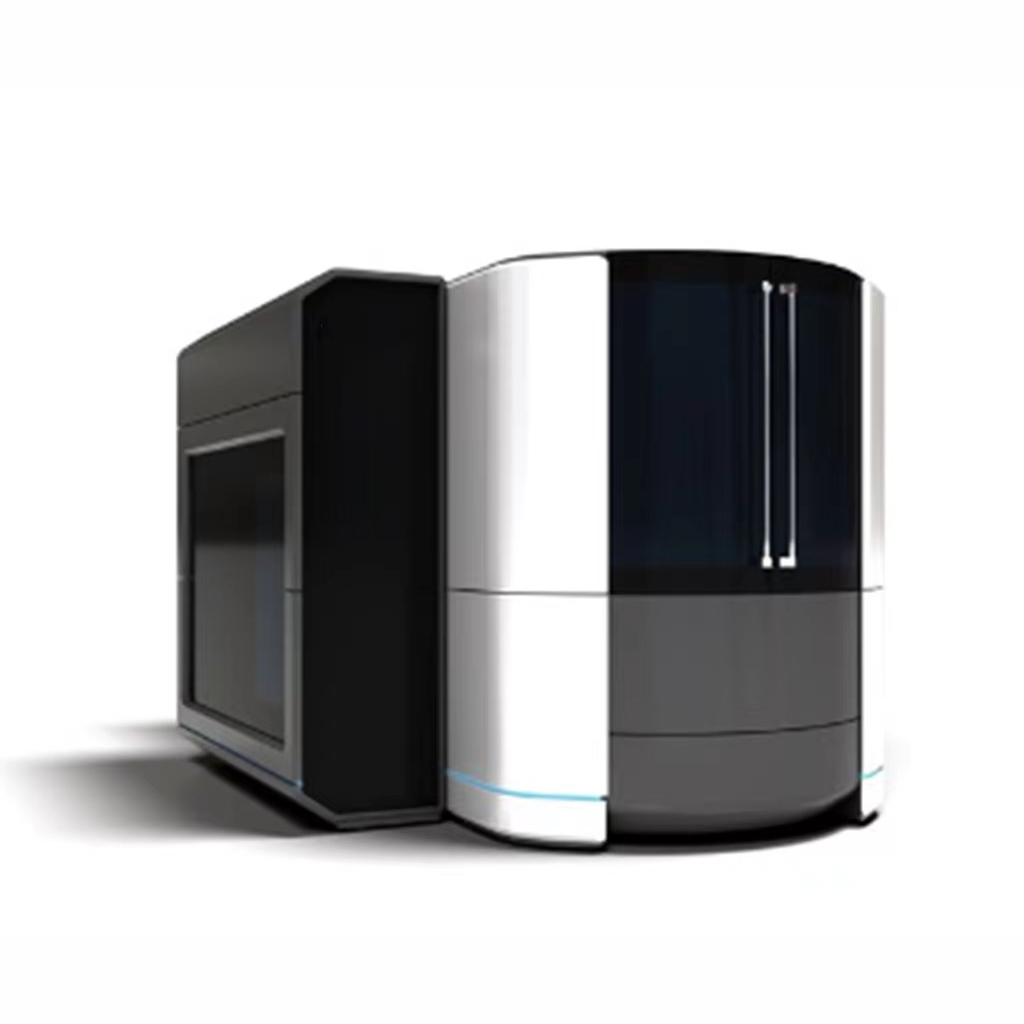

Vertical Machining Center

1.Product Introduction

If you are looking for a high-quality Vertical Machining Center that can handle various workpiece materials and support a wide range of fields, the Kaihua Mold Vertical Machining Center is the perfect choice. Our state-of-the-art machining center can handle materials such as iron, aluminum, and die casting with ease, making it ideal for both heavy cutting and precision machining.

One of the key advantages of the Kaihua Mold Vertical Machining Center is its traditional inclined column structure, which allows for high acceleration and deceleration speeds. This ensures that workpieces are machined quickly and accurately, regardless of the complexity of the job.

In addition, our machining center features precision positioning technology, with cooling of the ball screw and bearing bracket to prevent chip failure. This guarantees that the machining process is always accurate and efficient, producing high-quality results.

We understand that precision and quality are essential for any machining application, which is why our vertical machining center is built to exacting standards. From the latest technology to the highest quality materials, we are committed to providing our customers with the best possible machining solutions.

If you are looking for a reliable, high-quality vertical machining center for your business, look no further than the Kaihua Mold Vertical Machining Center. Contact us today to learn more about our products and services, and how we can help you achieve unparalleled precision and quality in your machining applications.

2.Advantages

· High Quality

· Short Cycle

· Competitive Cost

3.Project Cases:

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.